Coal powder ignition device and method

A technology for pulverized coal and combustion area, which is applied to pulverized coal ignition devices and the field of ignition, can solve the problems affecting the reliability and stability of pulverized coal combustion, reduce the reliability of pulverized coal combustion, and increase ignition energy consumption, etc. The effect of shortening ignition time, reducing ignition energy consumption and improving ignition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

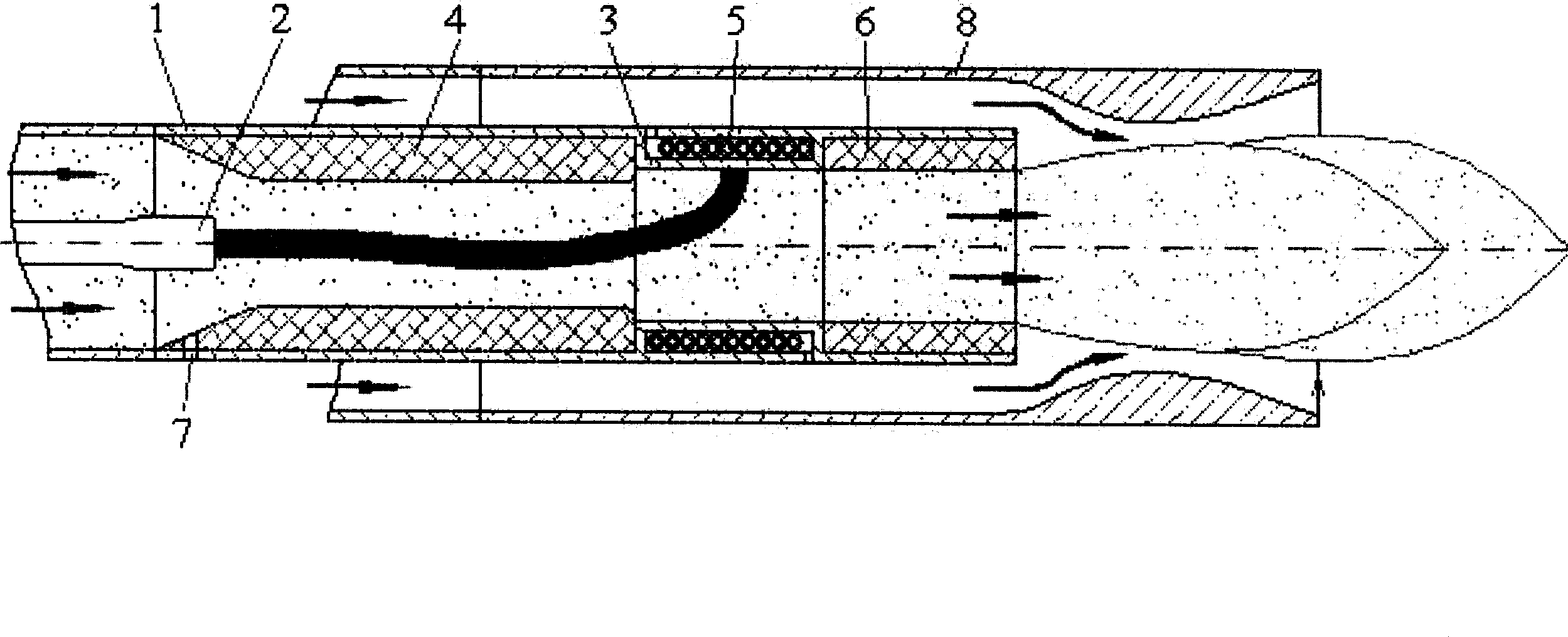

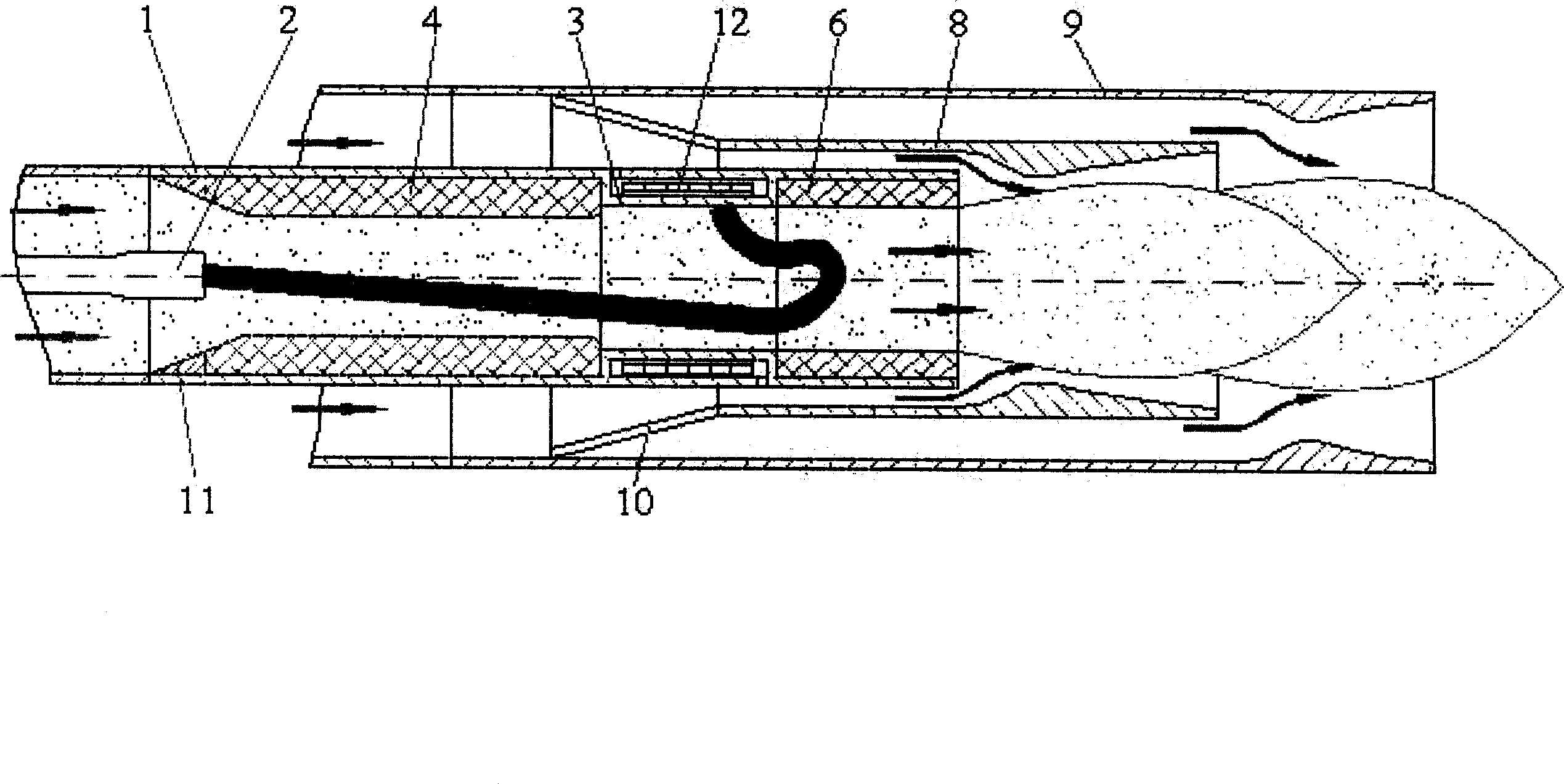

[0021] see figure 1 . 1 is the pulverized coal transportation pipeline, and the arrow in it indicates the flow direction of the pulverized coal-air mixture. 2 is the cathode of the plasma arc generating device, which is in the shape of a round rod, connected to the negative electrode of the power supply through a water-cooled metal pipe, and placed in the center of the pulverized coal transportation pipeline by an insulating support. The two are coaxial, and the front end of the cathode points to the direction of the pulverized coal flow. 3 is the anode of the plasma arc generating device, which is a metal pipe made of conductive material, which is connected as a whole with the pulverized coal transportation pipeline by a conventional mechanical connection method. A water-cooled interlayer is provided in the middle of the anode pipeline, and the solenoid electromagnetic coil 5 and the anode cooling mechanism are installed in the water-cooled interlayer. The cooling mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com