Method for oil extraction in multi-bottom and multi-branch well by artesian injection

A self-flowing water injection and multi-branch technology, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of uneconomical oilfields and large investment, so as to save well slots, increase recovery, and improve oil formation The effect of formation pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

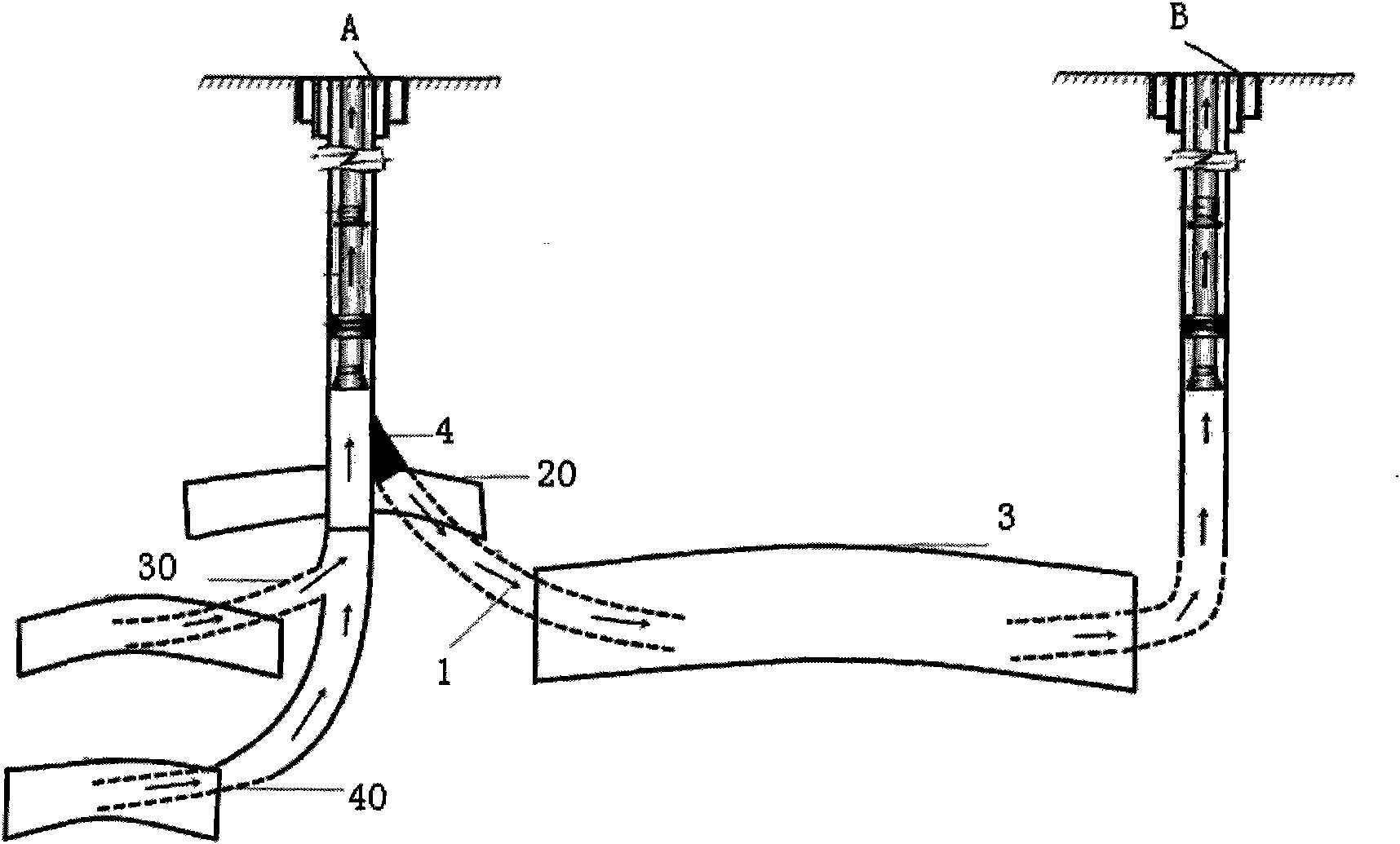

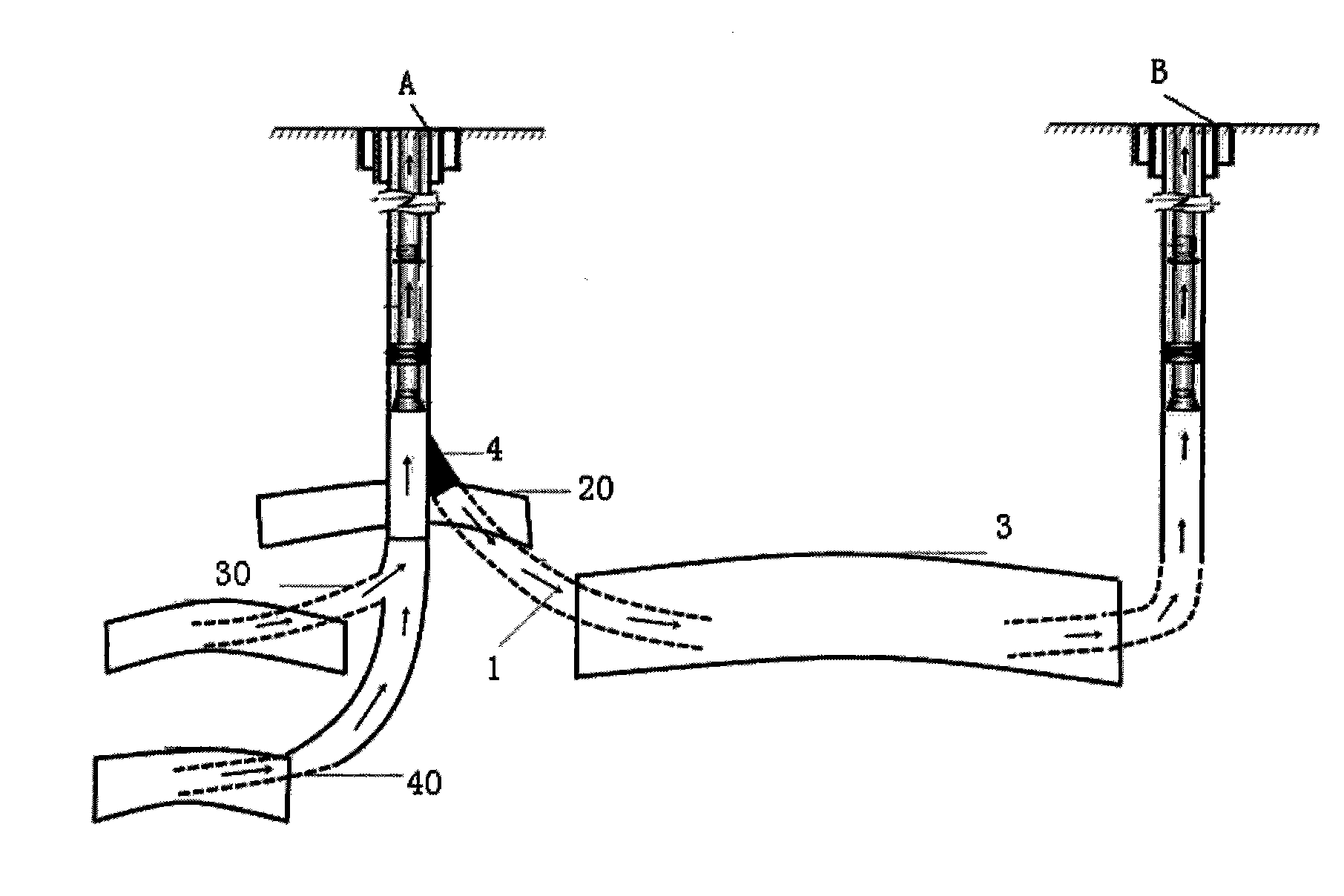

[0017] Depend on figure 1 Visible: the present invention is realized through the following steps:

[0018] Drill the first well A and the second well B;

[0019] In the first well, the water injection branch 1 is drilled using conventional drilling techniques, and the water injection branch passes through the water layer 20 and the oil layer 3 under the water layer 20;

[0020] After the water injection branch is drilled, the slotted pipe is lowered to communicate between the water layer 20 and the oil layer 3; due to the high pressure of the water layer and the low pressure of the oil layer 3, the water in the water layer automatically flows into the oil layer 3 to replenish energy for the oil layer 3;

[0021] After the slotted pipe of the water injection branch 1 is lowered, the cement plug 4 is used to seal the junction of the branch and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com