An Experimental Method for Methane Huff and Puff Assisted by Foam Oil in Thin Heavy Oil Reservoirs

The technology of a heavy oil reservoir and an experimental method is applied in the field of foam oil-assisted methane huff and puff in thin-layer heavy oil reservoirs, which can solve the problem of low recovery factor, and achieve the advantages of improving recovery factor, improving development effect, and increasing formation pressure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

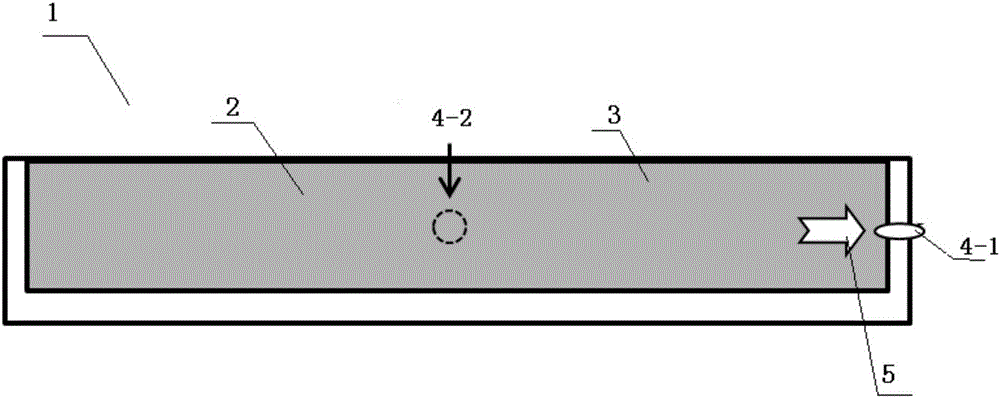

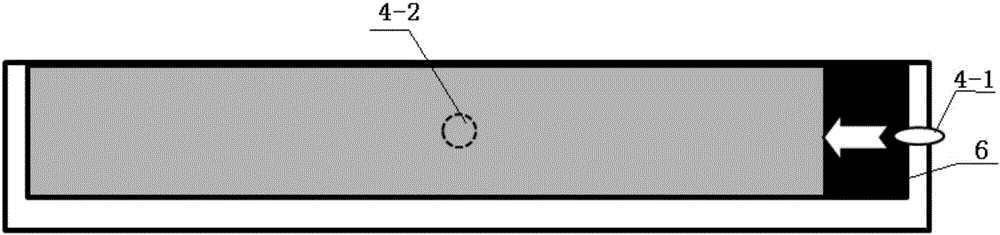

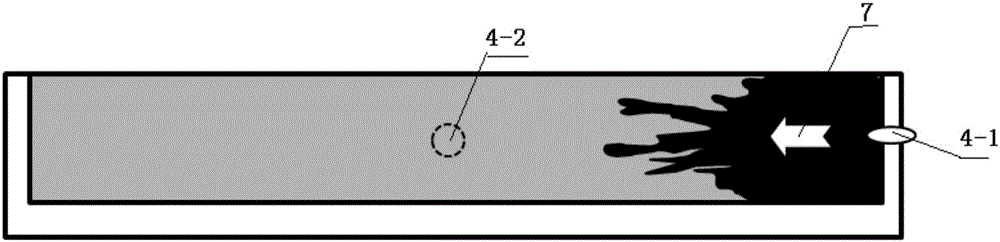

[0058] An experimental method for foam oil-assisted methane huff and puff in thin-layer heavy oil reservoirs. The experimental method uses a one-dimensional visual sand filling model 1, including a sand filling cavity 2 filled with quartz sand layers, and a sand filling cavity 2 in the sand filling cavity 2. A plurality of injection / production ports 4-1 are arranged around, and the liquid in the sand filling cavity 2 flows along a one-dimensional direction; the experimental method includes the following steps:

[0059] 1) inject formation crude oil into the quartz sand layer 3 of the described sand filling chamber 2, so that the model pressure is the formation pressure of the thin-bed heavy oil reservoir to be simulated; from figure 1 The shown injection / production port 4-1 injects crude oil into the formation, so that the sand filling model pressure is 430 psig formation pressure;

[0060] 2) Heavy oil decompression and cold recovery stage: depressurization and cold recovery ...

example 2

[0100] The experimental method as described in Example 1, wherein, in this example, the one-dimensional visual sand filling model used in the experiment is the same as Example 1, and the difference is that:

[0101] The porosity, permeability and original oil saturation of the one-dimensional visualized sand filling model after sand filling in the step 1) are 35.22% and 33.33 μm respectively 2 and 89%.

[0102] The step 2) in the step-down cold recovery recovery rate R 冷采 was 30.04%.

[0103] In described step 3), concrete steps are as follows:

[0104] First, inject methane gas, the injection pressure is greater than 650 psig, and the gas injection volume is 4759 cm 3 , the sand filling model pressure before braising is 367psig;

[0105] Next, inject the oil-soluble surfactant solution that makes described viscous oil form foam oil, injection pressure is 50psig, and concentration is 0.5wt%;

[0106] Finally, the distance from the front edge of the oil-soluble surfactant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com