Device for combusting and heating crude oil by using oilfield casing associated gas

A technology of associated gas and casing, applied in water heaters, fluid heaters, lighting and heating equipment, etc., to achieve the effects of reducing pollution, high heat utilization rate, and good heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

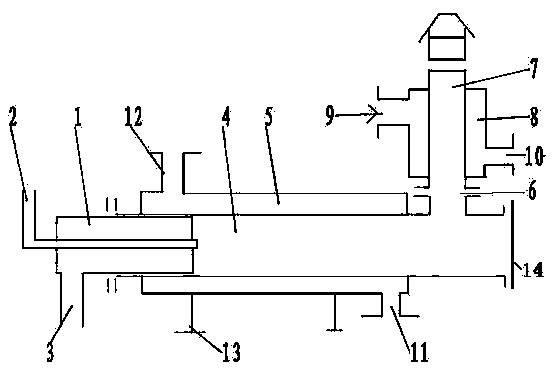

[0016] The device for burning and heating oil field casing associated gas of the present invention, such as figure 1 As shown, it includes a burner 1, a combustion chamber 4 and a flue 7. The burner is located at one end of the combustion chamber, the burner is provided with an air inlet 3 and a fuel inlet 2, and the combustion chamber is connected with the flue. The device is equipped with a high-temperature heat-absorbing chamber 5 and a low-temperature heat-absorbing chamber 8. The high-temperature heat-absorbing chamber 5 is arranged coaxially with the combustion chamber. The high-temperature heat-absorbing medium inlet 11 is located on the side where the high-temperature 12 is located at the side of the high-temperature combustion chamber close to the burner. The low-temperature heat-absorbing chamber 8 is arranged coaxially with the flue, the low-temperature heat-absorbing medium inlet 9 is located on the side of the flue outlet, and the low-temperature heat-absorbing ...

Embodiment 2

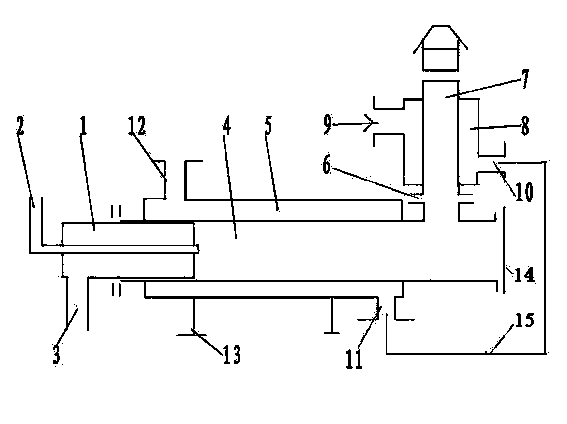

[0019] Another embodiment of the present invention is as figure 2 As shown, the low-temperature endothermic medium outlet 10 of the low-temperature endothermic chamber is connected to the high-temperature endothermic medium inlet 11 of the high-temperature endothermic chamber through a connecting pipeline 15, so that the high-temperature endothermic chamber 5 and the low-temperature endothermic chamber 8 are connected in series. Other structures are the same as in Embodiment 1.

[0020] Both the high-temperature heat-absorbing medium and the low-temperature heat-absorbing medium in this embodiment are crude oil. Crude oil at 40°C enters the low-temperature heat-absorbing chamber 7 through the low-temperature heat-absorbing medium inlet 9, and enters the high-temperature heat-absorbing chamber 5 through the low-temperature heat-absorbing medium outlet 9, the connecting pipeline 15, and the high-temperature heat-absorbing medium inlet 11 after being heated to 80±10°C. After be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com