Methods and compositions for improving hydrocarbon recovery by water flood intervention

a technology of hydrocarbon recovery and flood intervention, which is applied in the direction of fluid removal, borehole/well accessories, chemistry apparatus and processes, etc., can solve the problems of water channeling through streaks/hairline fractures with higher permeability, water cuts in oil producing wells increasing, scaling problems in susceptible wells, etc., to improve the injection profile, increase hydrocarbon production, and improve the effect of hydrocarbon production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

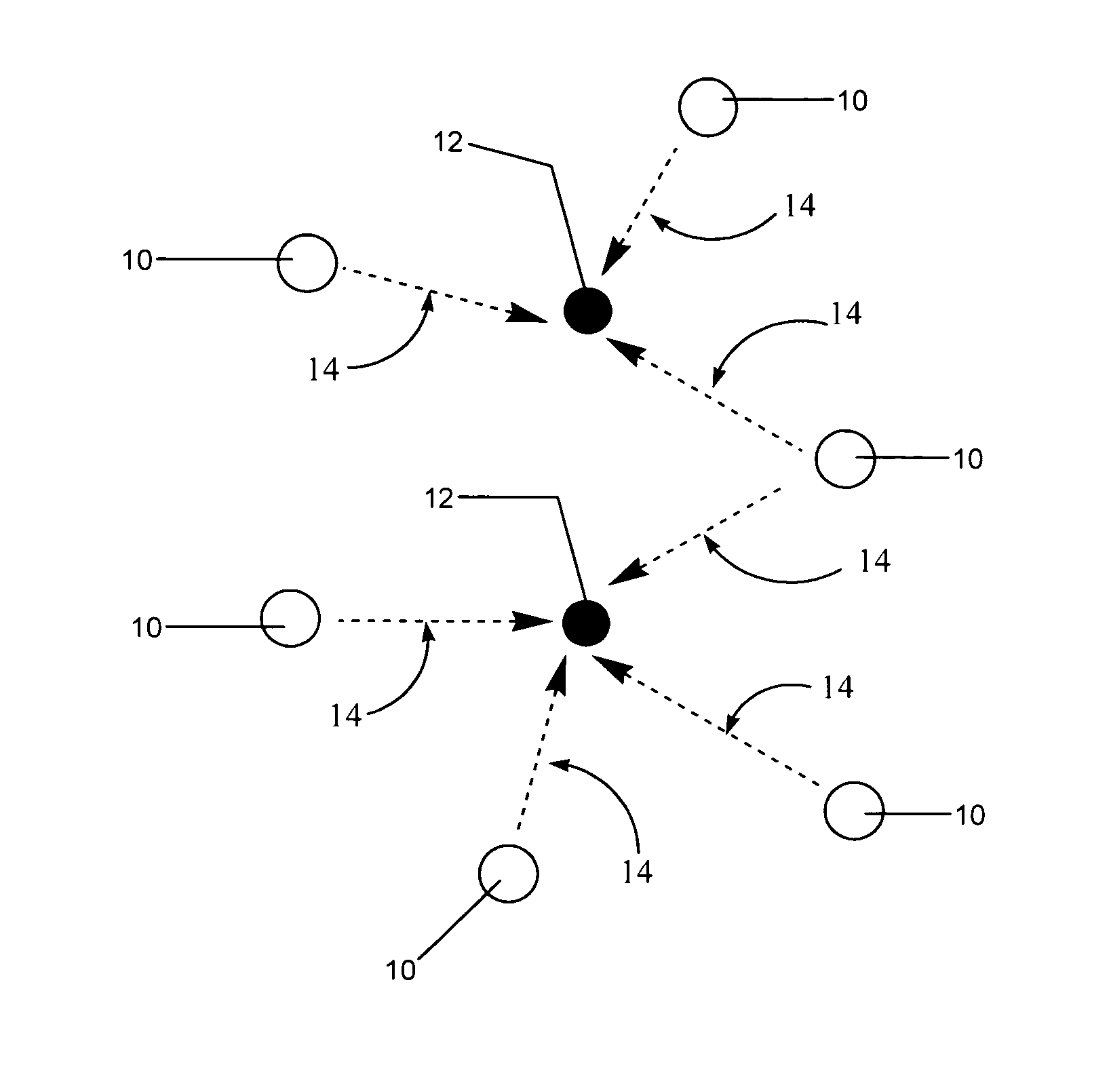

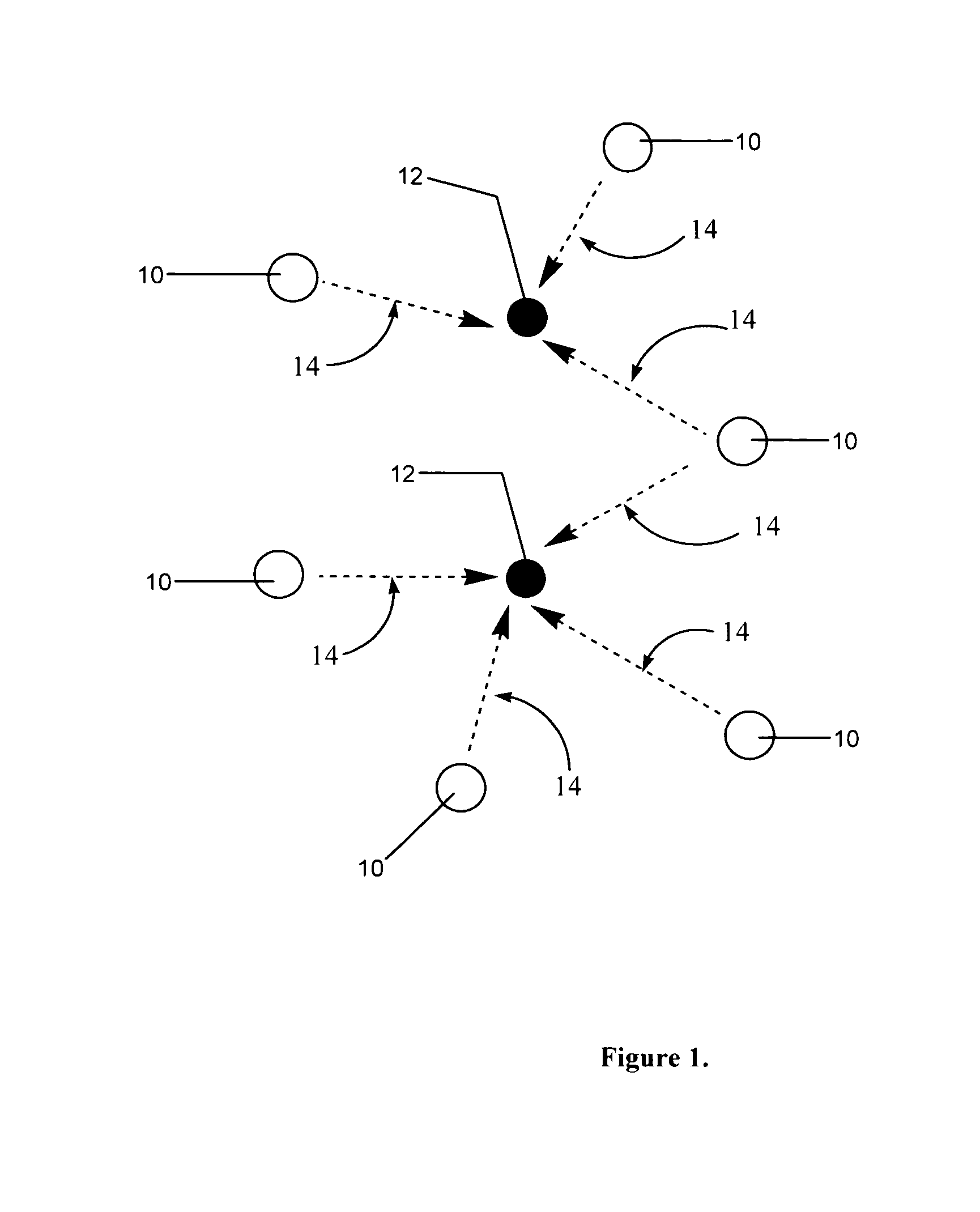

Image

Examples

example 1

General Procedure for Parallel Core Flow Testing

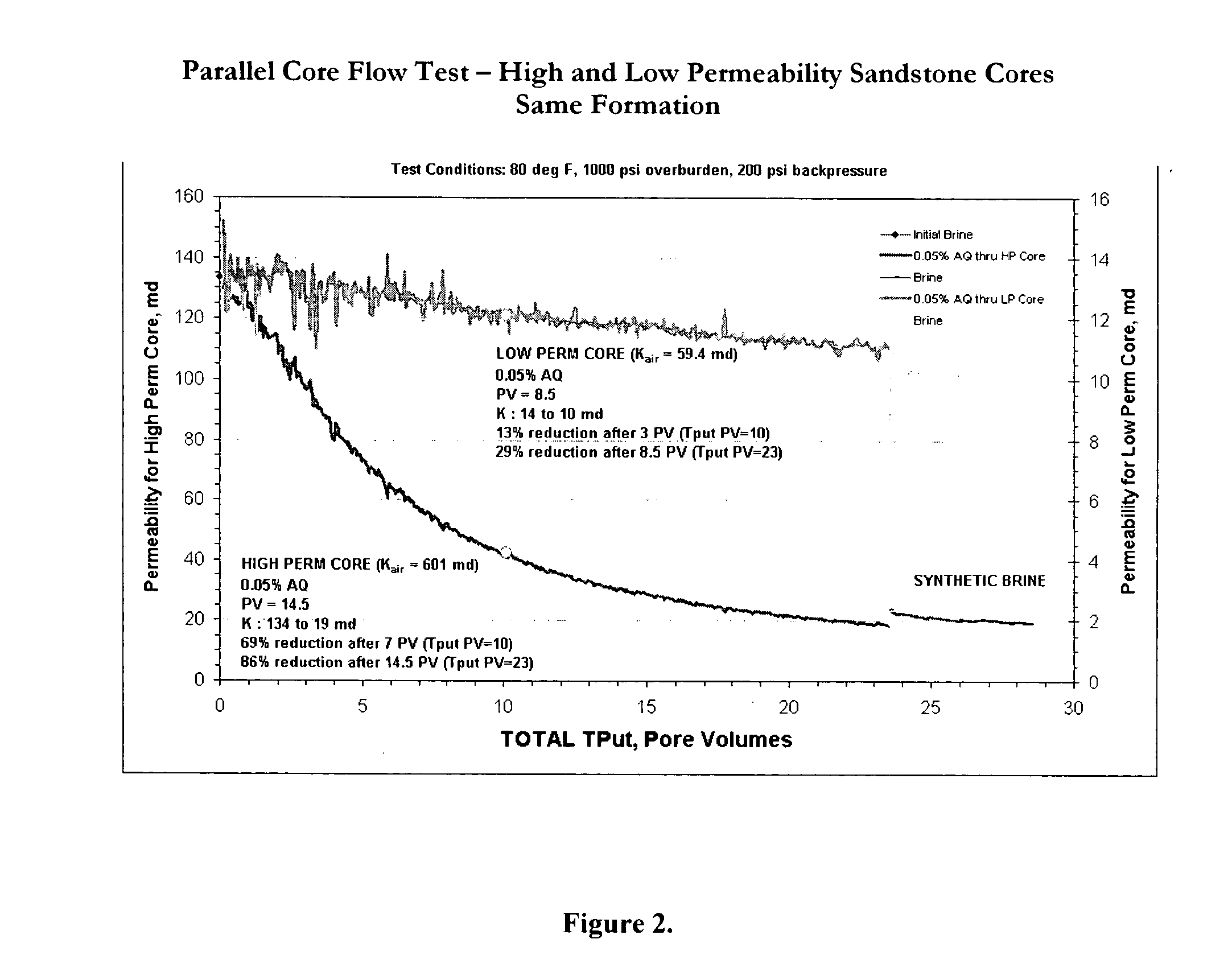

[0070] The first step is to determine the test core dimensions and baseline properties. The test cores were placed into a suitable core-holder of a parallel flow test apparatus. The dry cores were then saturated with brine. Following saturation, the cores were heated to the test temperature(s) with the required confining and back pressures. The initial permeability to brine through both cores was then determined independently by establishing flow in an arbitrary injection direction (to simulate injection into the reservoir) at constant rate until steady state. AquaCon™ (available from BJ Services Company, Houston, Tex.) treatment fluid was then injected through the parallel flow apparatus, at a constant rate of approx. 0.3 ml / min, in the injection (treatment) direction. AquaCon™ treatment flow and pressure drops through both the high permeability and low permeability cores were measured simultaneously. The duration of this AquaCon™ tr...

example 2

Parallel Core Flow Test

[0072] The purpose of this test was to determine AquaCon™ (BJ Services Co., Houston, Tex.) effectiveness in reducing water flow through high permeability thief zones without significantly affecting the permeability in lower permeability zones. For this test, a high permeability sandstone core that was 10 times more permeable than the low permeability core (air permeability contrast of 10:1) was used. The result of the linear parallel core flood testing with 0.05% AquaCon™ is shown in Table 1 below.

TABLE 1Before TreatmentAfter TreatmentRatio ofAquaConRatio ofHighTreatmentPermeabilityHighCoreKbrine:Low%PoreReductionKbrine:LowTestTypeKairKbrineKbrineConc.VolumesKbrinefrom Initial %Kbrine1Sandstone6011349.60.05231986%1.959.4140.051029%

[0073] A total of 23 pore volumes of AquaCon™ treatment were injected through the parallel core flow apparatus. As expected, the majority of the AquaCon™ treatment flowed preferentially through the high permeability core that resu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com