Method for raising recovery efficiency of super-deep low permeability heavy oil reservoir

A technology for heavy oil reservoirs and ultra-deep layers, applied in the field of improving the recovery of ultra-deep low-permeability heavy oil, can solve the problem that SAGD technology cannot be applied to ultra-deep low-permeability heavy oil reservoirs, and it is difficult for ultra-deep low-permeability heavy oil reservoirs to be applied. It can improve the development effect, expand the scope of steam sweep, and increase the daily oil production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the above and other objects, features and advantages of the present invention more comprehensible, preferred embodiments are listed below and described in detail in conjunction with the accompanying drawings.

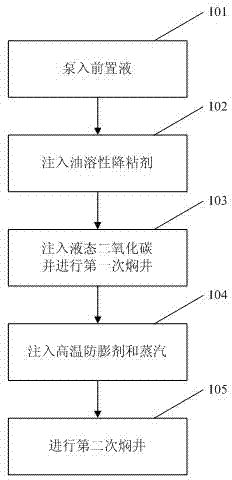

[0020] Such as figure 1 as shown, figure 1 It is a flow chart of a specific embodiment of the method for enhancing the recovery factor of the ultra-deep low-permeability heavy oil reservoir of the present invention.

[0021] In step 101, the pad fluid is pumped in, and then the sand-carrying fluid and sand grains are squeezed into the formation at a pumping pressure higher than the fracture pressure of the formation, and the pump is stopped and the well is shut down after continuing to inject the displacement fluid. The pre-fluid ratio is 35%-55%, and the pumping displacement of the sand-carrying fluid is 3.0m 3 / min-5.0m 3 / min, the sand concentration is 15%-28%. In one embodiment, the sand grains are quartz sand or ceramsite sand. The proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com