Electromagnetically determining the relative location of a drill bit using a solenoid source installed on a steel casing

a solenoid source and magnetic determination technology, applied in the direction of borehole/well accessories, survey, etc., can solve the problems of insufficient control, insufficient control, and inability to provide precise control, etc., to achieve the effect of long rang

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

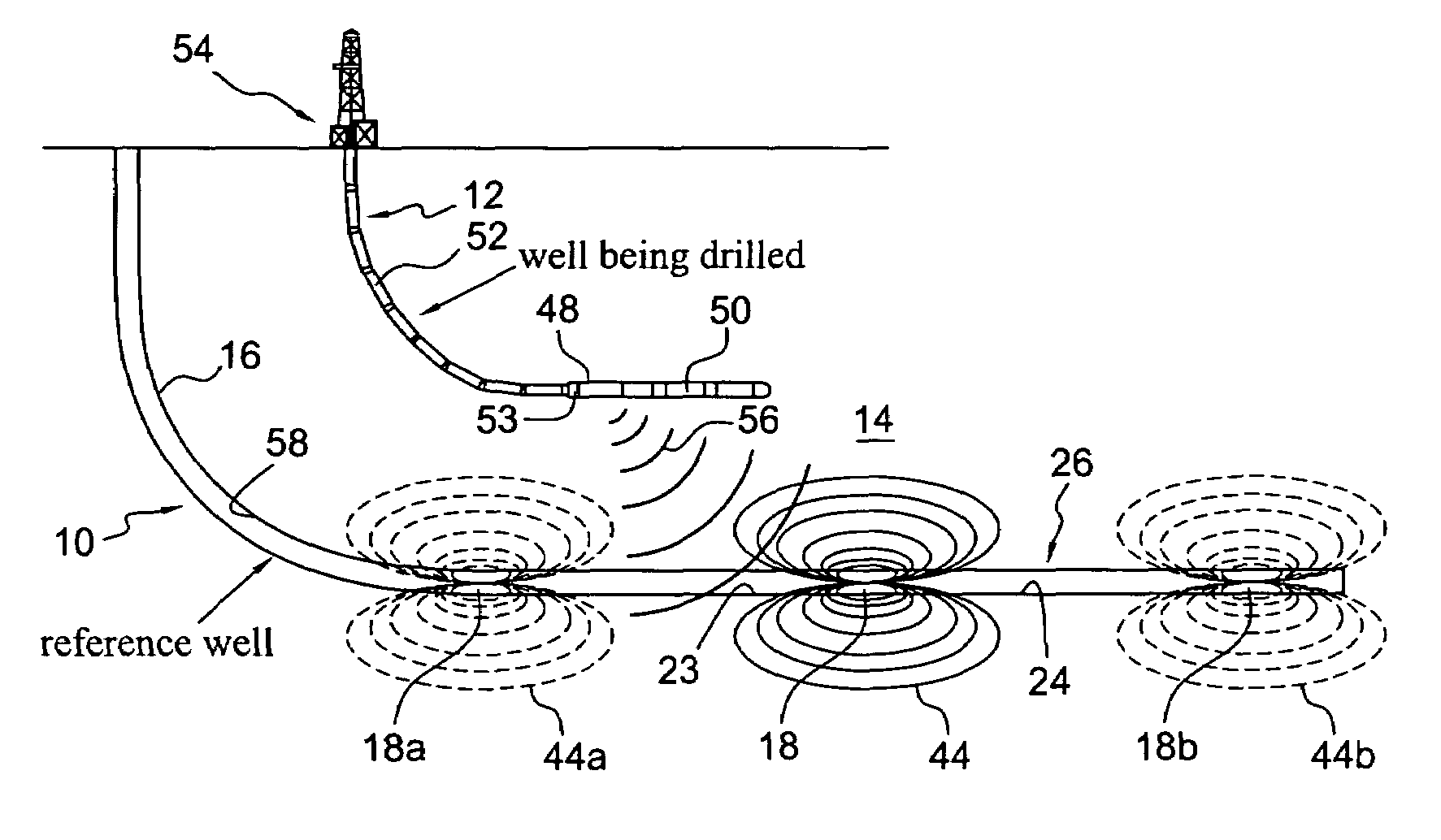

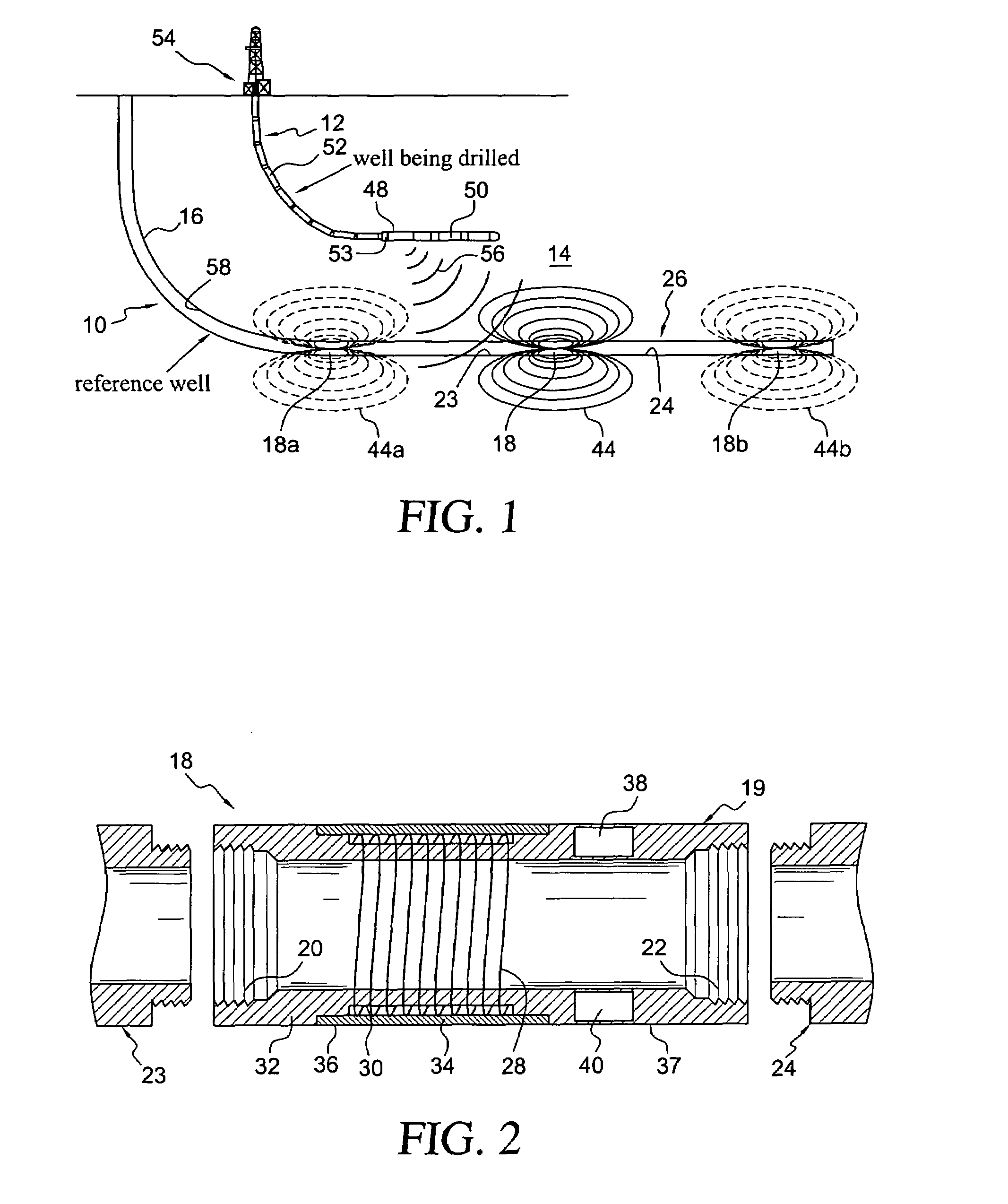

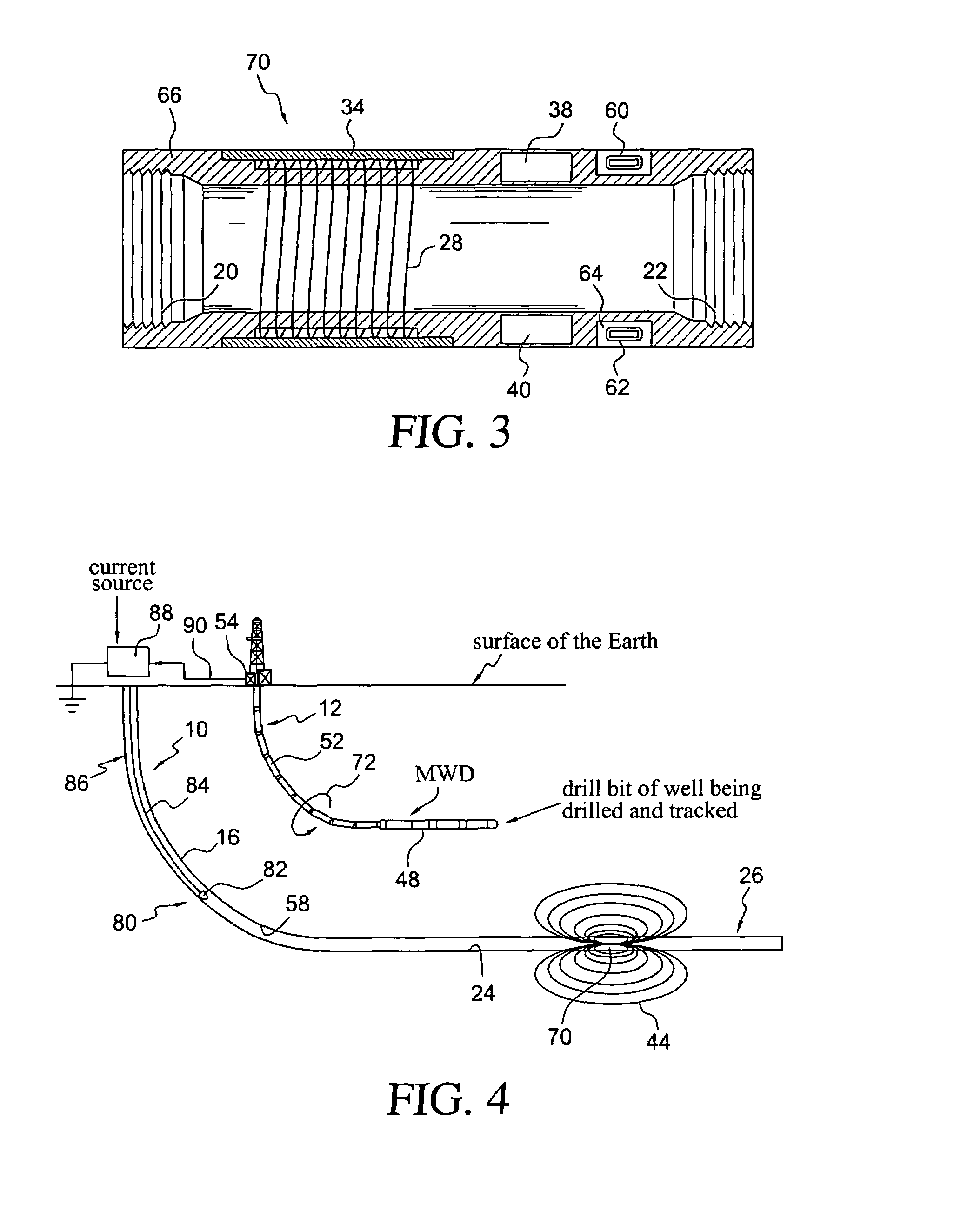

[0024]Turning now to a more detailed description of the present invention, there is illustrated in FIG. 1 an overall view of a pair of wells 10 and 12 in an oil field 14 for use in SAGD (steam assisted gravity drainage) production of oil from a non-flowing bitumen hydrocarbon formation. As illustrated, well 10 is a previously drilled and cased horizontal well which serves as a reference well, while well 12 is being drilled along a path that is near, and parallel to, a horizontal portion of the first well. In this important SAGD application, steam will be injected into the upper well 12 to melt the bitumen to allow it to flow to the lower well 10, from which it is pumped to the Earth's surface. An important specification of such a well pair is that the horizontal portions of the pair, which are located in the hydrocarbon formation, must be precisely parallel to each other, with a precisely specified separation. Typically, the well pair will have a horizontal reach of 1.5 km with a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com