Low-cost environment-friendly oil-soluble viscosity reducing agent for super heavy oil

An oil-soluble, viscosity-reducing agent technology, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of affecting the effect of dilution, uneven mixing, and increased demand for dilution, and achieves a huge environmental impact. Benefits, thin oil saving rate, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0020] Example 1 oil-soluble viscosity reducer

[0021] Raw material composition:

[0022] Main ingredient 30%

[0023] Azobisisobutyronitrile (initiator) 0.5%

[0024] Toluene (solvent) 69.5%;

[0025] Wherein, the above-mentioned main ingredients are waste oil, styrene and maleic anhydride in a mass ratio of 3:1:1.

[0026] Preparation:

[0027] First fully dissolve the maleic anhydride with toluene at room temperature, then add waste oil, styrenebutene in turn, and then add the initiator azobisisobutyronitrile, and continuously stir the reaction at 80°C, normal pressure, and nitrogen protection 3 hours, obtain the oil-soluble viscosity reducer among the present invention.

example 2

[0028] Example 2 oil-soluble viscosity reducer

[0029] composition:

[0030] Main ingredient 37%

[0031] Azobisisobutyronitrile 0.3%

[0032] Diesel (solvent) 62.7%;

[0033] Wherein, the above-mentioned main ingredients are waste oil, styrene and maleic anhydride in a mass ratio of 3:2:2.

[0034] Preparation:

[0035] First, fully dissolve maleic anhydride with diesel oil at room temperature, then add waste oil, styrene in sequence, and then add initiator azobisisobutyronitrile, and continuously stir and react at 80°C, under normal pressure, under nitrogen protection, for 3 Hour, obtain the oil-soluble viscosity reducer among the present invention.

example 3

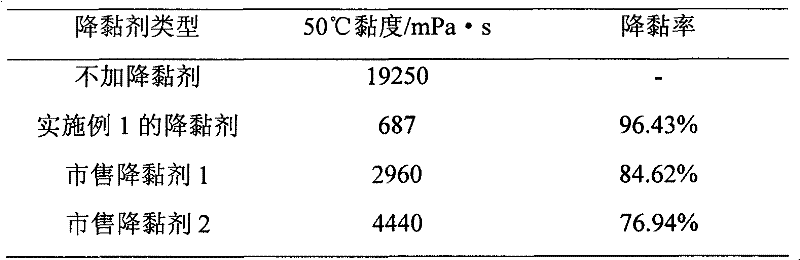

[0036] Application of Example 3 in Thick Oil Viscosity Reduction in TH12126 Well of Tahe Oilfield

[0037] Tahe TH12126 heavy oil can flow when the formation temperature is 140°C, but not flow at room temperature, and the viscosity is 89×10 at 50°C. 4 mPa s. After adding the viscosity reducer prepared in Example 1 with a mass fraction of 1% of the system, the viscosity of the system at 50°C was 7650 mPa·s, and the viscosity reduction rate was 99.14%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com