Rock breading rod for producing shock waves and manufacturing method of rock breaking rod

A production method and technology of rock-breaking rods, which are applied in earth cube drilling, discharge machinery, ground mining, etc., can solve problems such as mining constraints of mineral resources and low density of electric energy storage, and achieve stable properties, guarantee of life safety, and safety sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

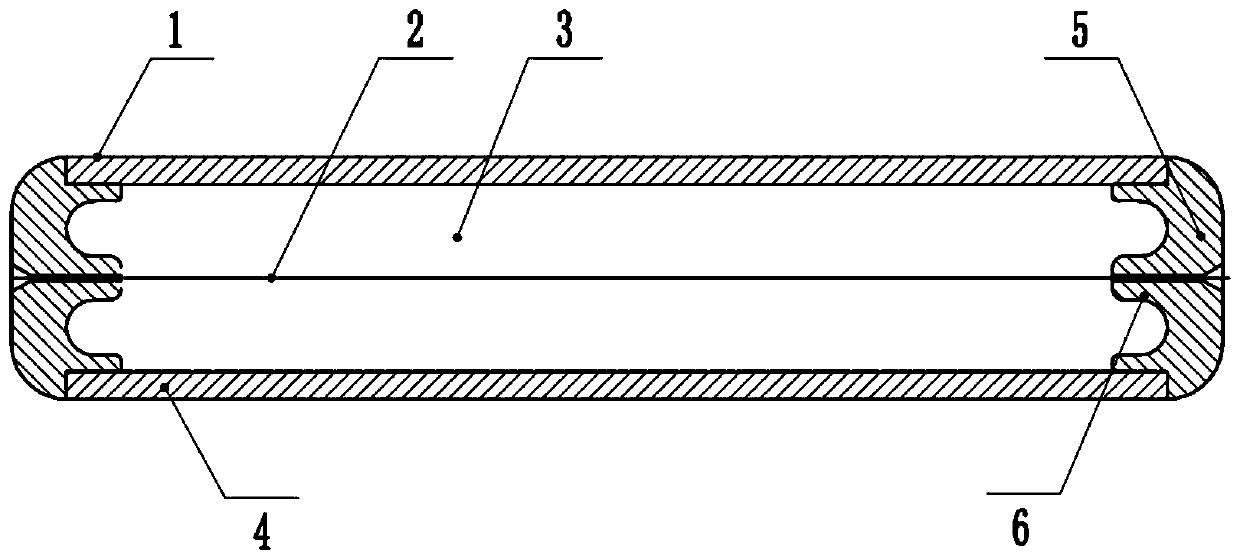

[0039] A rock-breaking rod used to generate shock waves, such as Figure 1 to Figure 3 As shown, it includes a shell 1 , a metal wire 2 and an energetic material 3 .

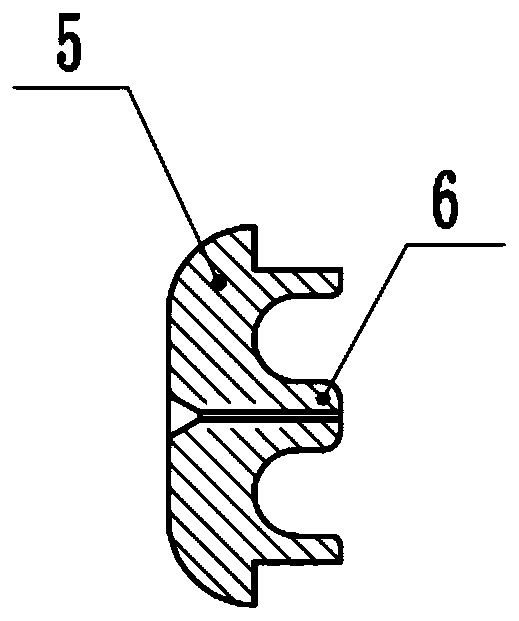

[0040] The shell 1 is a hollow straight tube with both ends closed. The outer diameter of the shell 1 is 32 mm, the length is 200 mm, and the wall thickness is 1 mm. The shell 1 includes a straight tube 4 and an end cap 5 .

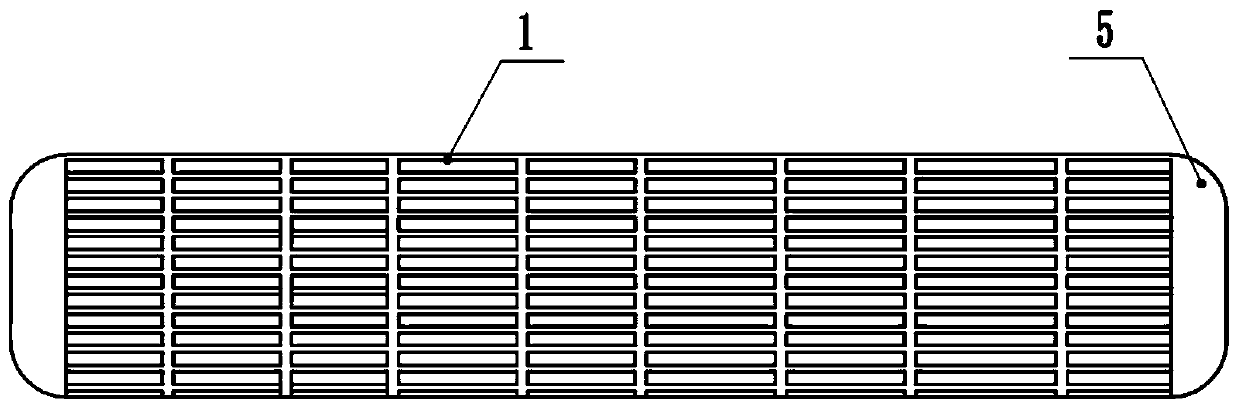

[0041] The straight pipe 4 is a tubular structure made of soluble aluminum-magnesium alloy; the high-strength aluminum-magnesium alloy can improve the compressive strength of the shell 1 . The outer surface of the straight pipe 4 is provided with multiple rows of groove assemblies along its axial direction, and each row of groove assemblies includes a plurality of rectangular grooves arranged along the circumference of the straight pipe 4, such as figure 2 As shown, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com