Land bridge method for recovery of pressed coal under highway

A technology for highways and goafs, applied in underground mining, roads, roads, etc., can solve the problems of inability to guarantee the normal passage of road vehicles, high repair costs, and fast driving speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

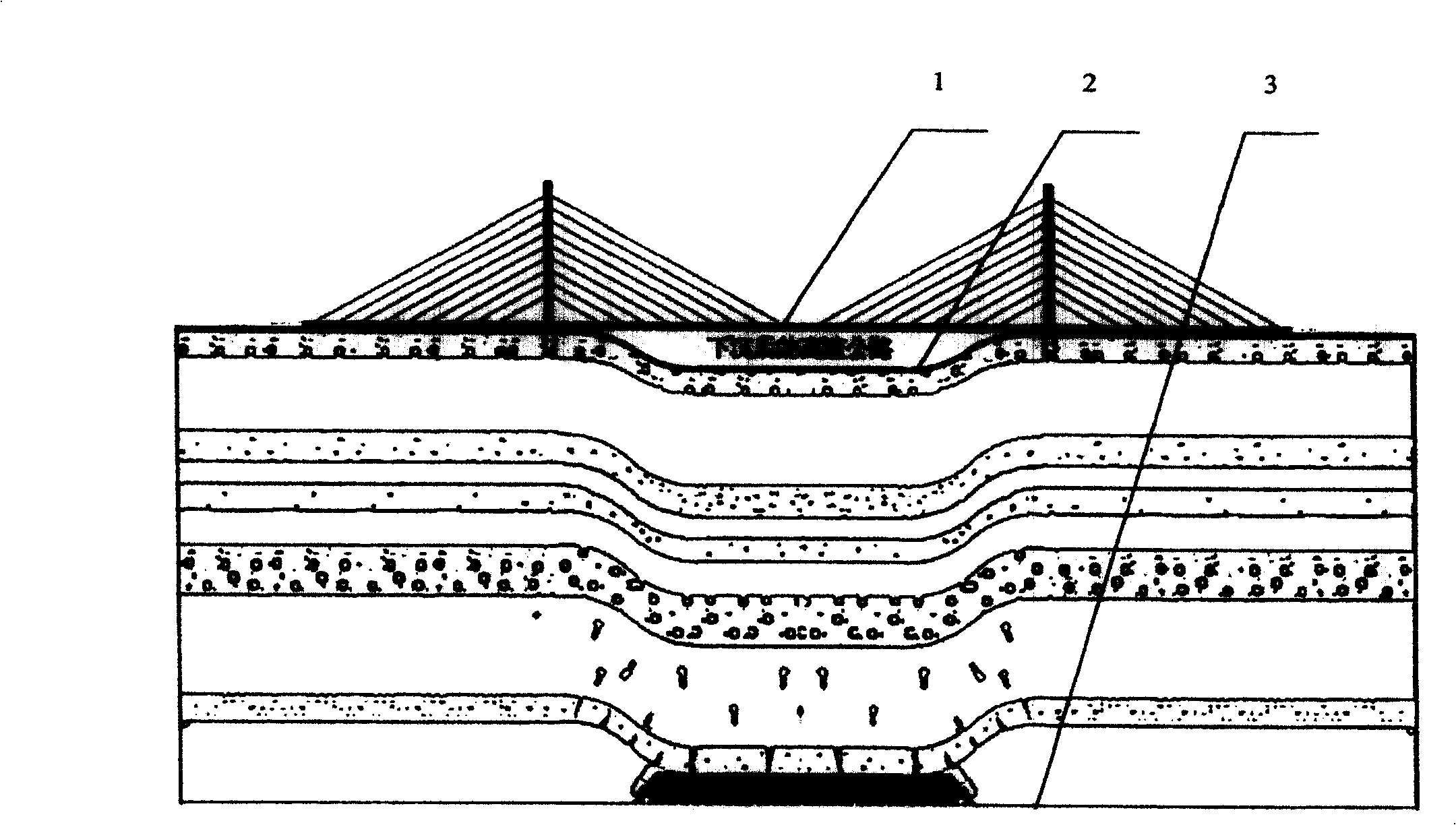

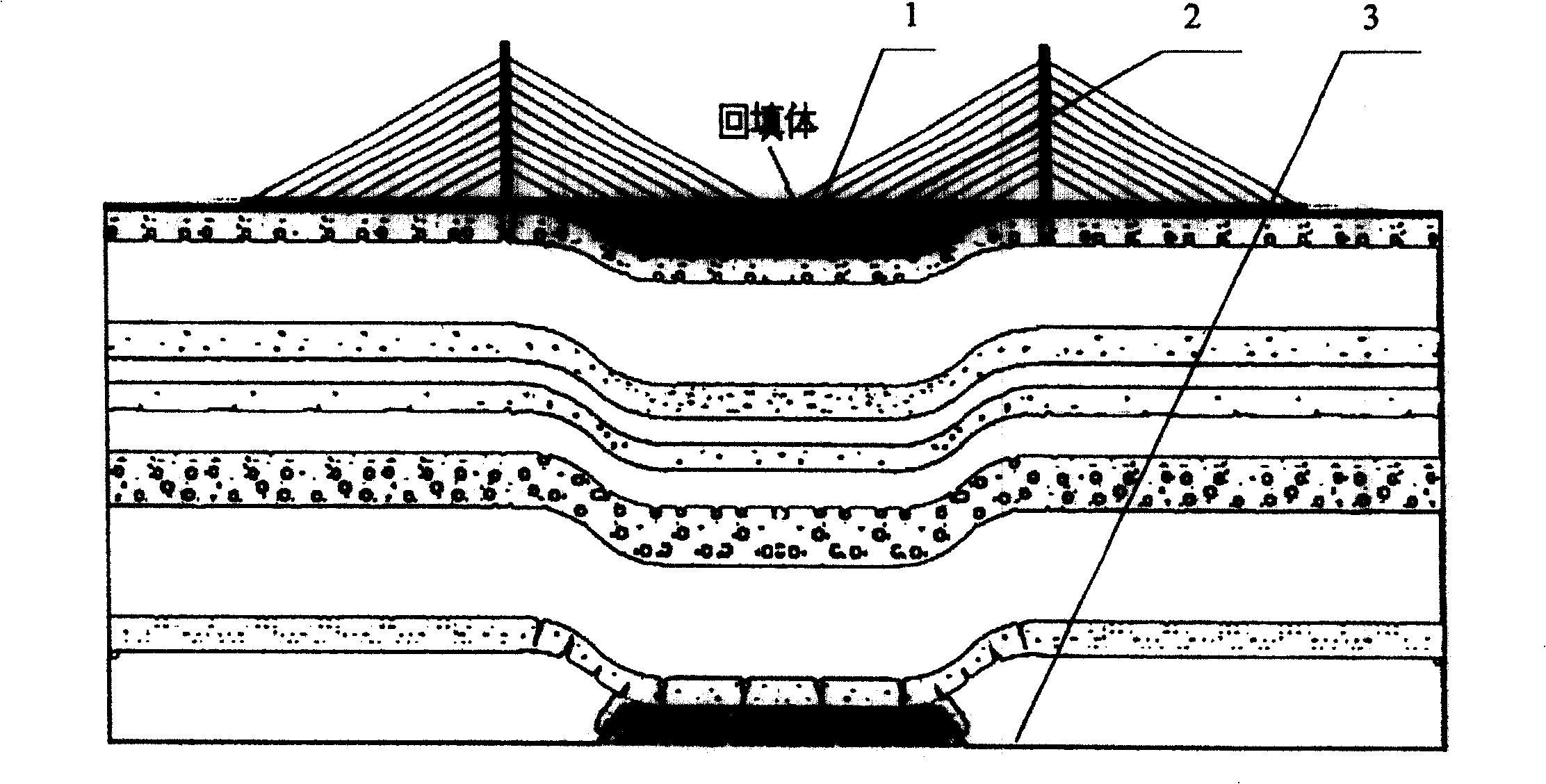

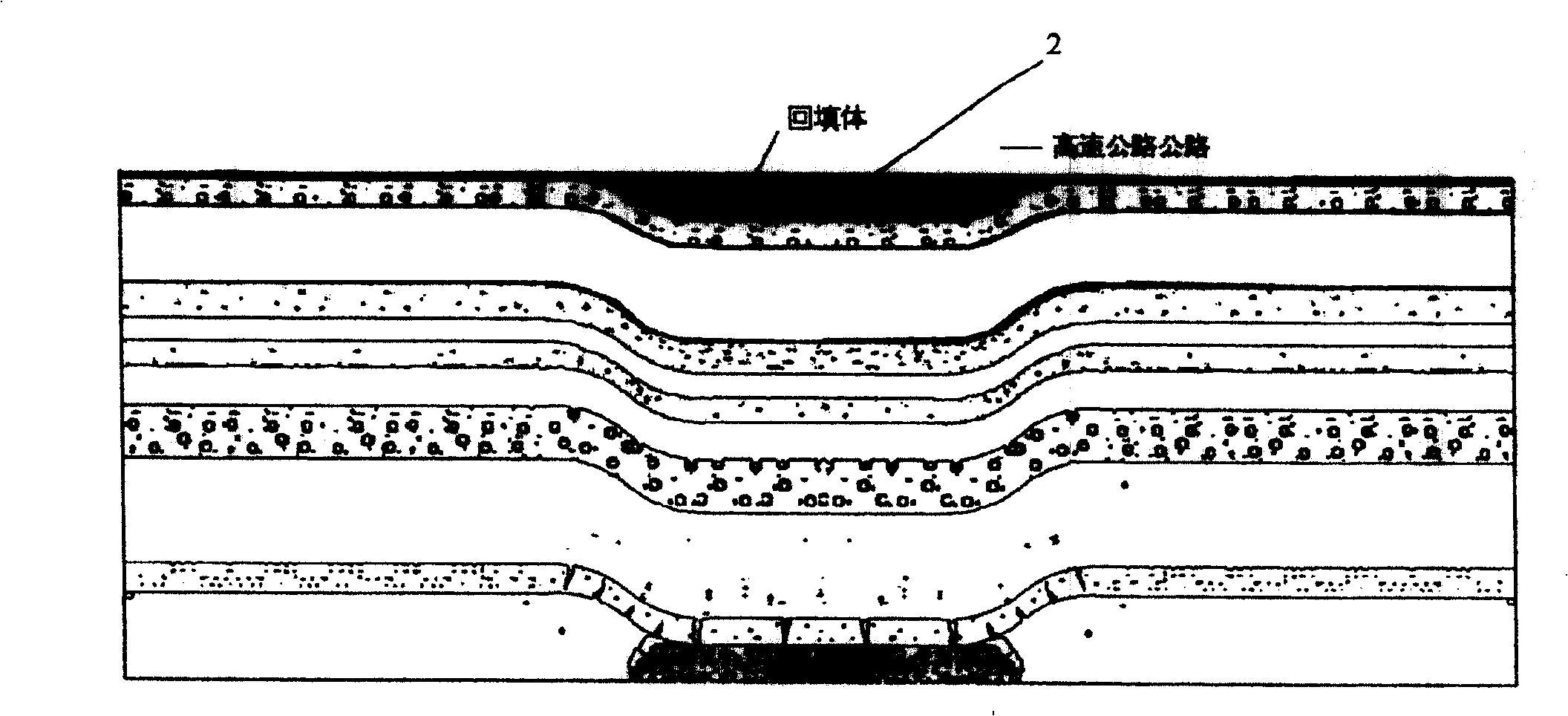

[0026] The embodiment of the dry bridge method for coal mining under the expressway described in the present invention is as follows: Figure 4 , 5 , Shown in 6, are three basic modes of pressing coal mining under expressway, also are the embodiment of the present invention's scheme. Under these three basic methods, the adjustable dry bridge can be erected in a detour by using the detour combination. open to traffic. At this time, the compressed coal on the side where the road is located is first mined, and the bypass combination adjustable dry bridge is erected at the unmined or goafed end. The mining face shown in the figure shows that several mining faces can be accommodated under the affected section of the road. In practice, the bypass dry bridge can have a span of about 3 kilometers, and it can accommodate about 10 mining working faces of about 300 meters below it. When mining affects the normal driving of the road, vehicles can pass through the adjustable dry bridge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com