Vortex machine

A vortex machine and vortex cavity technology, applied in centrifuges, cyclone axial reversible devices, cyclone devices, etc., can solve the problems of high cost of seawater desalination, easy aging of catalysts, waste of energy, etc. Equipment operation efficiency, the effect of cheap seawater desalination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

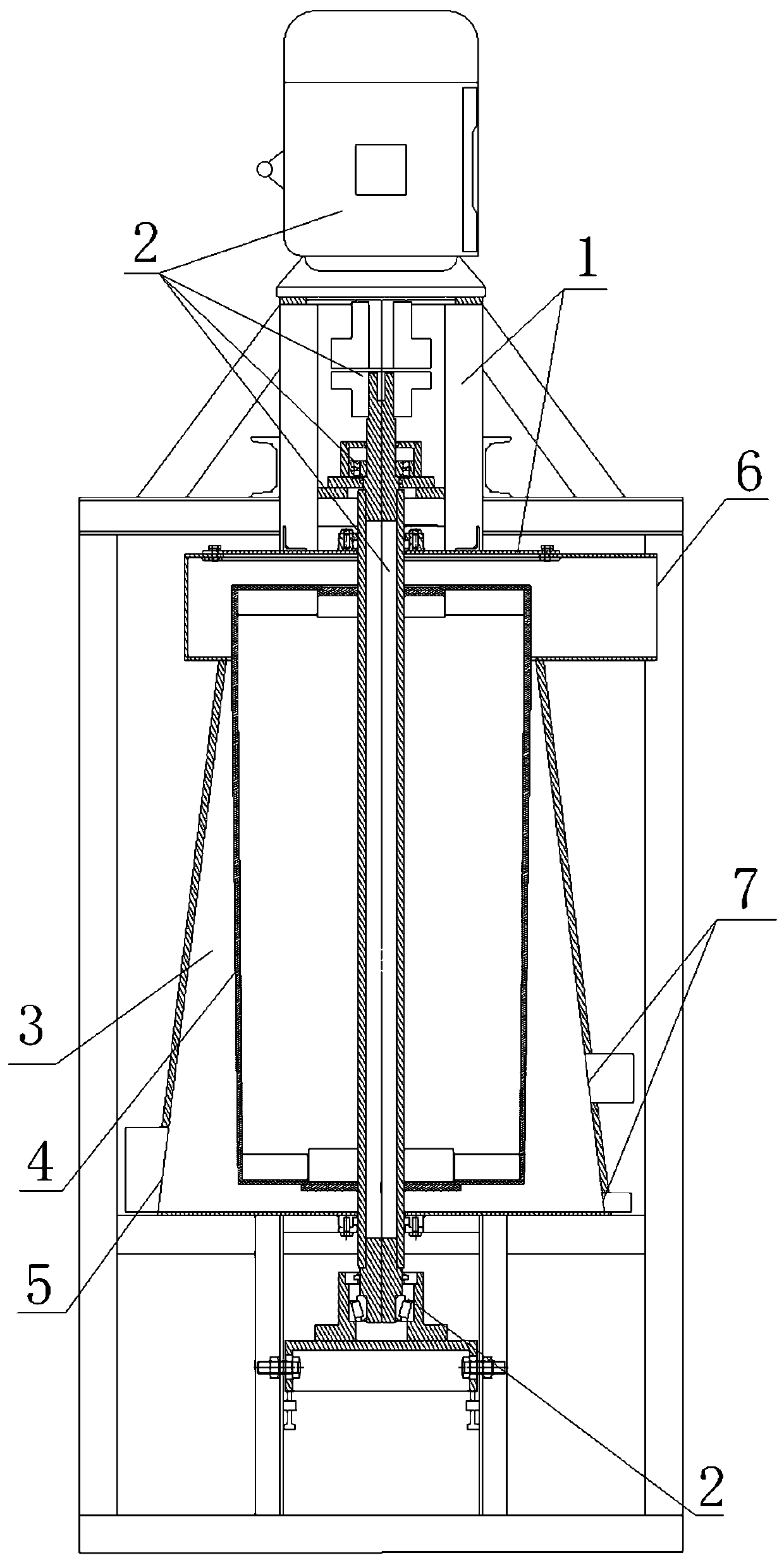

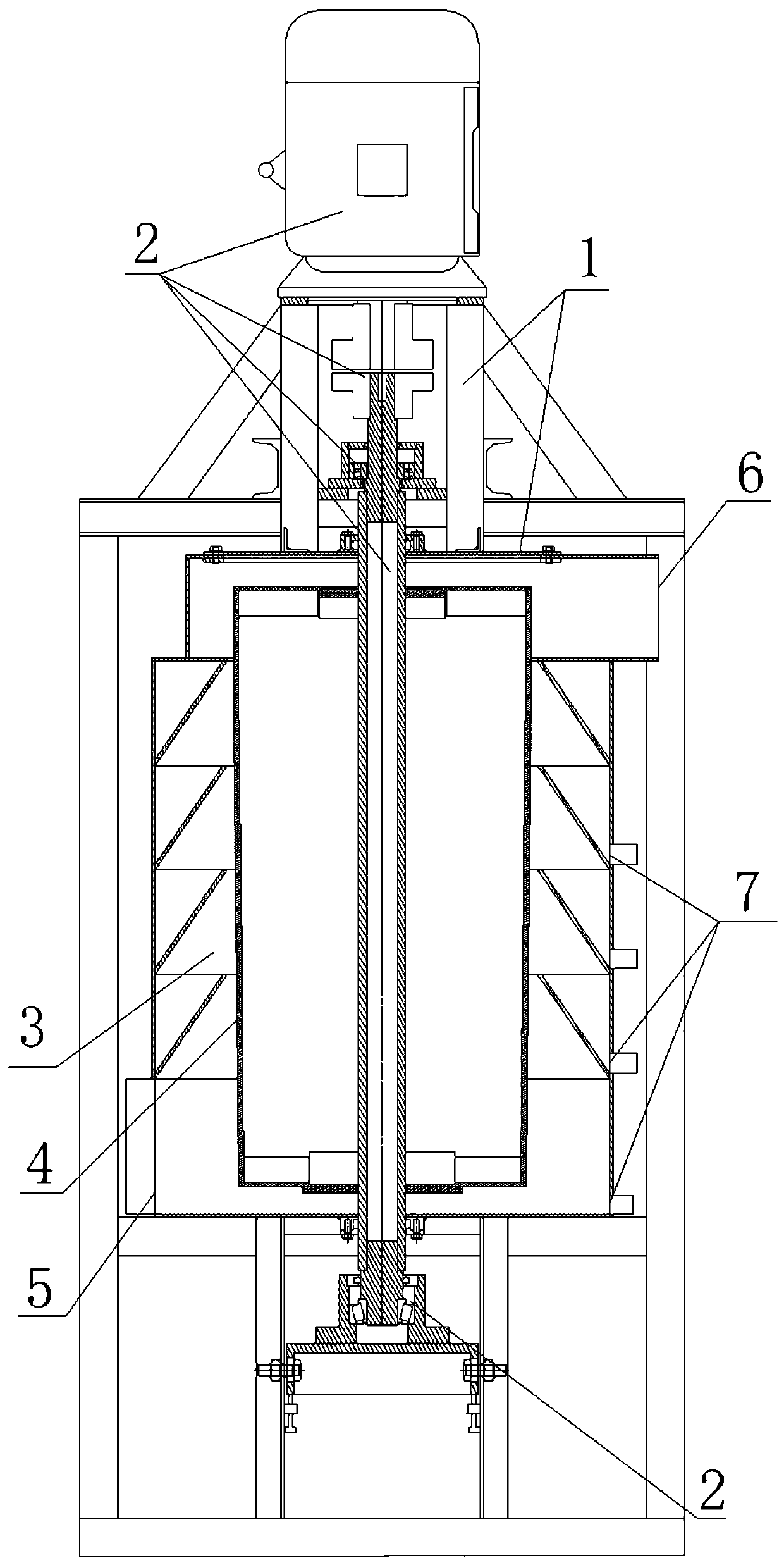

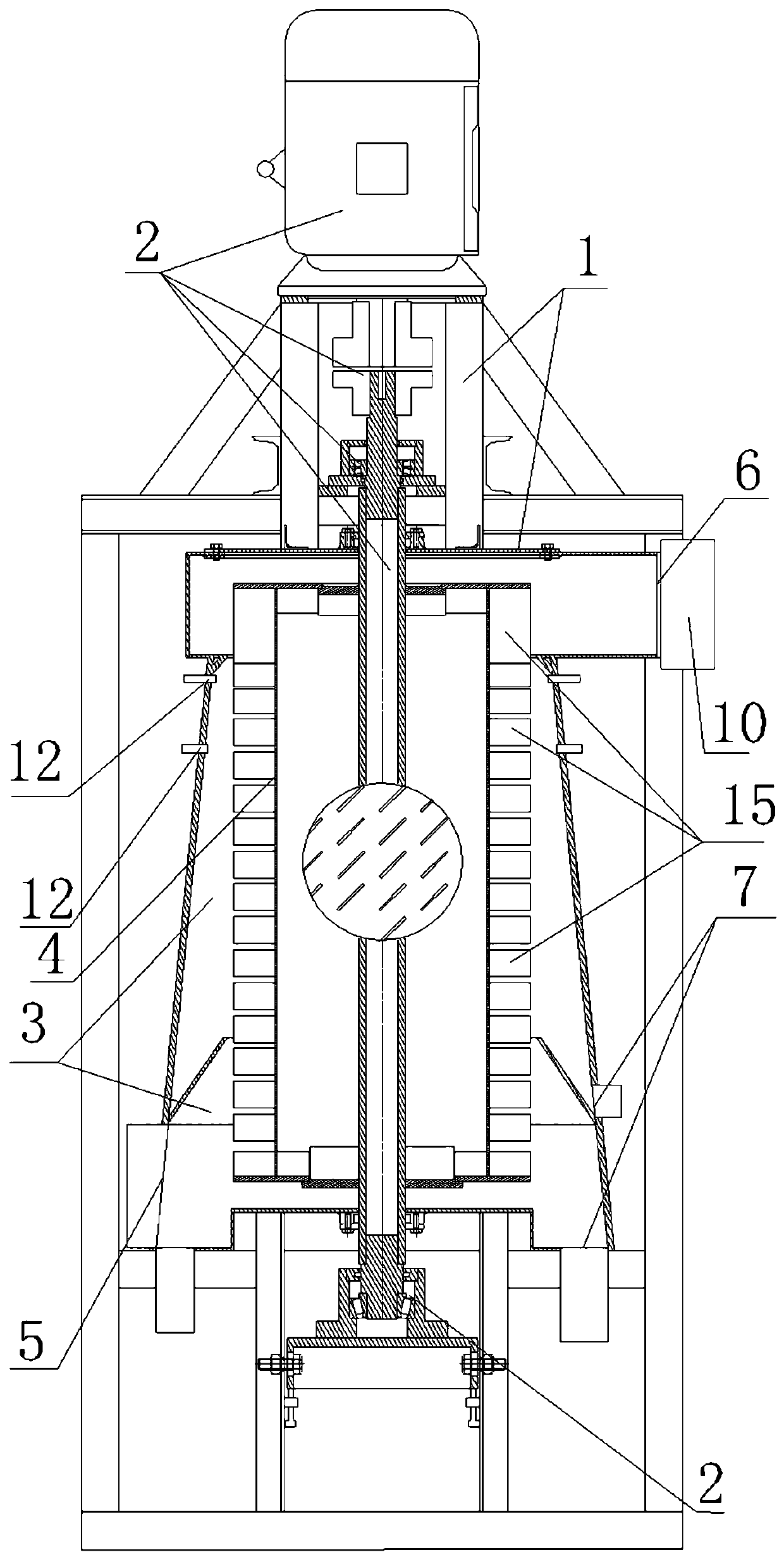

[0062] The main structure of the vortex machine includes a housing 1 and a transmission device 2. The transmission device 2 is arranged on the housing 1. The vortex chamber 3 is arranged in the housing 1. The transmission body 4 with the outer periphery as the working surface is arranged in the vortex chamber 3. The transmission device 2 and The transmission body 4 is connected. When the transmission device 2 drives the transmission body 4 to rotate, the outer periphery of the transmission body 4 drives the working medium to rotate and flow in the eddy current chamber 3 around the transmission body 4. One end of the eddy current chamber 3 is provided with the eddy current chamber inlet 5, and the other end of the eddy current chamber 3 is provided with Outlet 6 of the vortex chamber, at least one section of the vortex chamber 3 has a circular cross-section and its inner diameter gradually narrows toward the outlet 6 of the vortex chamber, and at least one discharge port 7 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com