Environment-friendly anti-landslide mining method

A mining method and an environment-friendly technology, which can be used in earth drilling, ground mining, underground mining, etc., can solve problems such as the inability to use explosives, damage to mountain vegetation, and geological disasters, achieve high space utilization value, avoid safety hazards, and internal huge space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

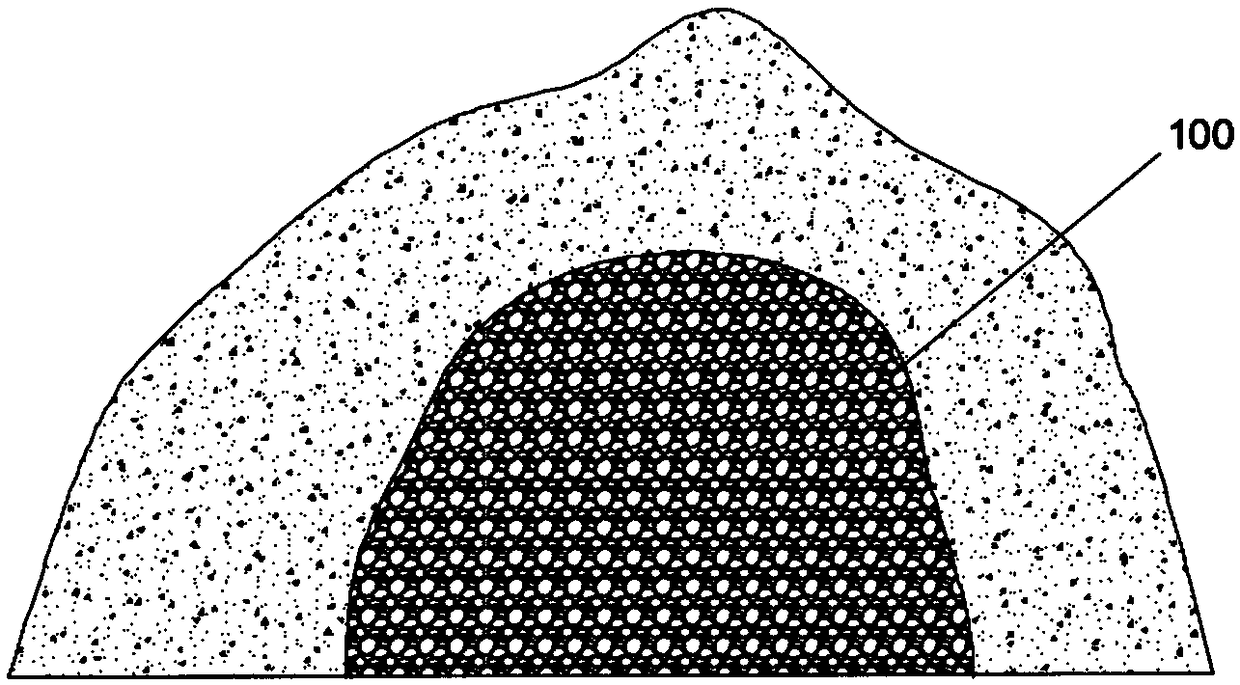

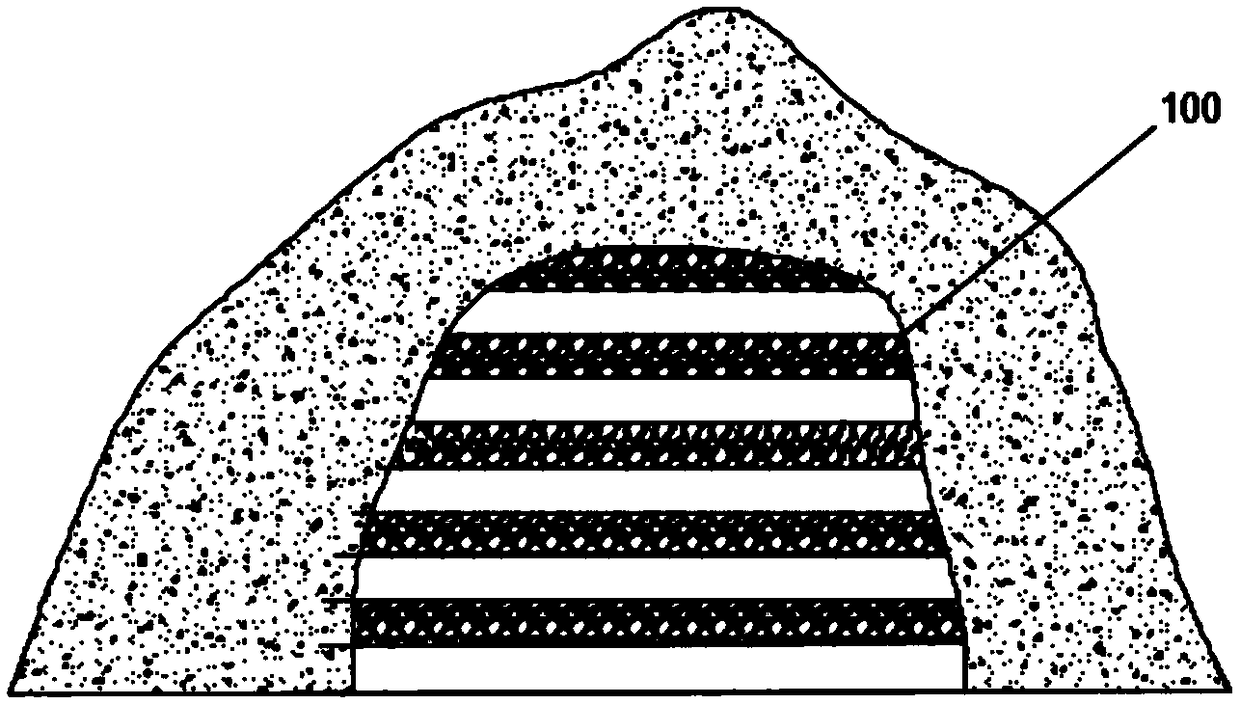

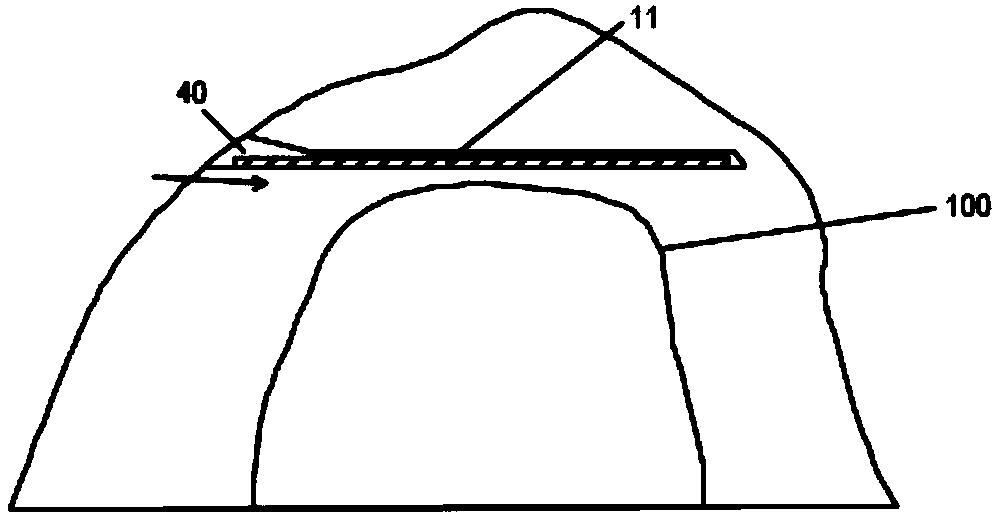

[0045]As an embodiment, the cantilever boring machine is used to excavate the upper layer of the mountain, and after entering the inner layer of the mountain rock, the mountain is stabilized by bolting 60, and a solid 0.5-1.5 meter thick rock is formed by tying steel bars and pouring concrete. The reinforced concrete layer is used as the first roof beam 11; the reinforced concrete layer on the top floor can avoid landslides to the greatest extent. Excavate the construction space 50 of 10 meters high at the first floor roof beam 11 bottoms, then piling prepares the first floor column 31, and downward depth is 45 meters, and upward height 10 meters, connects support with the first floor roof beam 11. Then mine the minerals in the lower part of the first layer of top beam 11, and after the first layer of minerals is mined to a depth of 50 meters, a first layer of mine cave 10 with a depth of 50 meters is formed; then piles are driven downward near the bottom of the first layer of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com