Exploitation method for coalbed methane multibranch remote-end communicated well

A multi-branch and interconnected well technology, which is applied in drilling equipment and methods, production fluids, drilling equipment, etc., can solve the problems of small oil and gas recovery, increase the number of wells, and low drilling rate, so as to improve drainage recovery. Gas efficiency, increased swept area, and improved single well production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

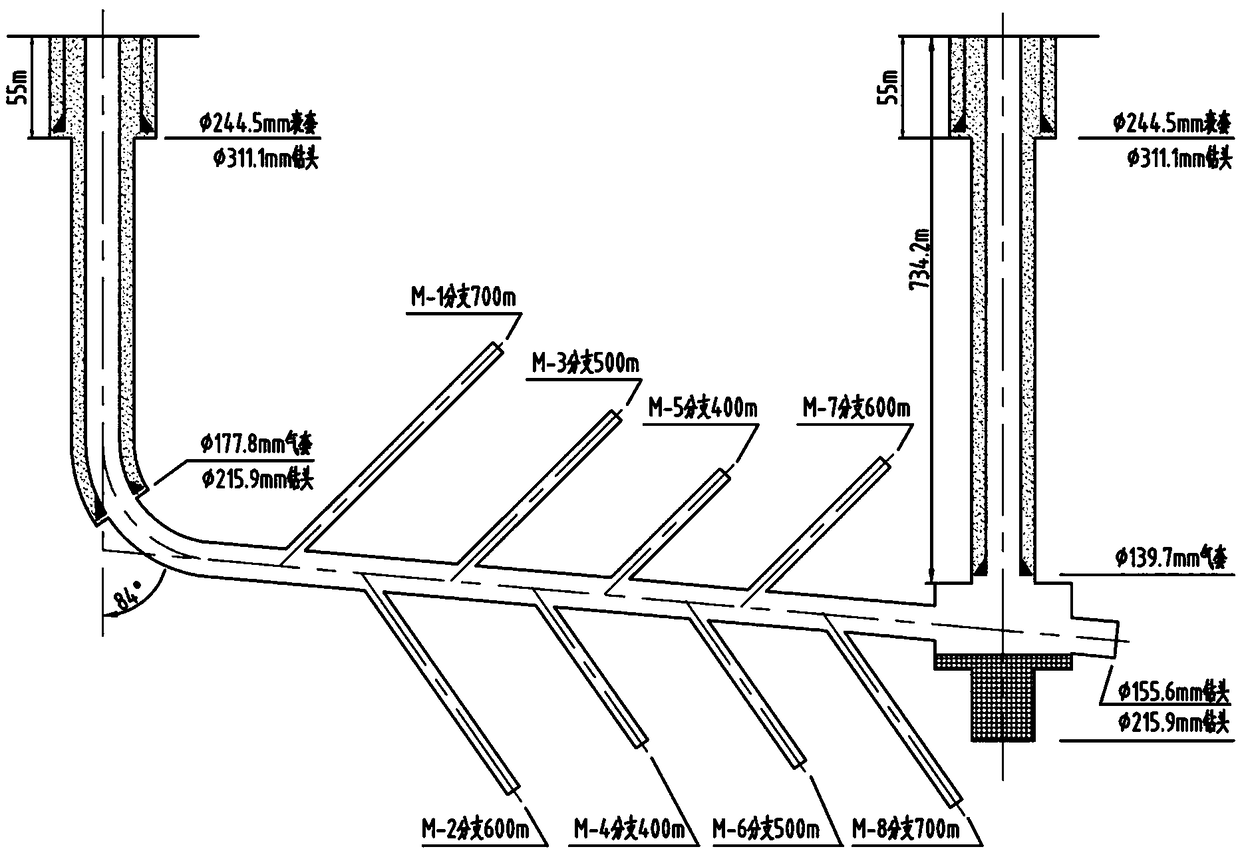

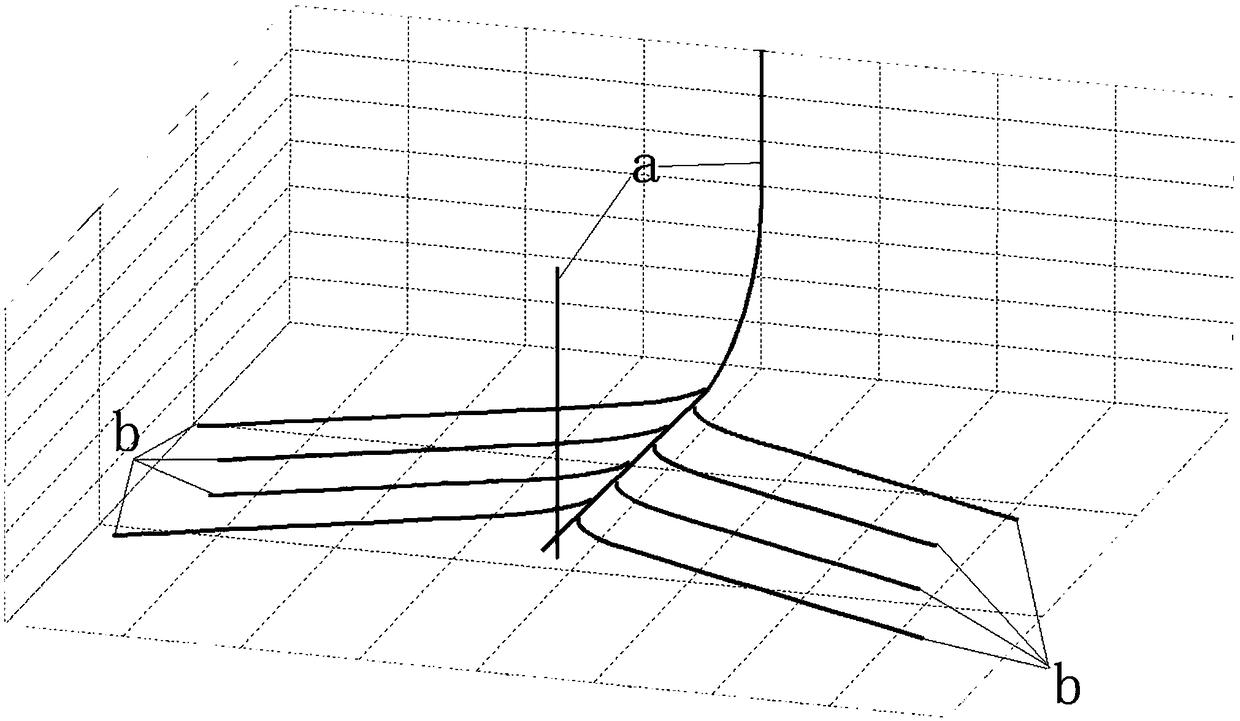

[0039] Such as figure 1 As shown, a method for developing coalbed methane multi-branched remote connected wells specifically includes the following steps:

[0040] (1) Drill with a Φ311.1mm drill bit to the designed surface casing depth at the first opening, seal the upper unstable, easy to leak, and easy-to-collapse layer with a Φ244.5mm casing, and use the inner pipe cementing process to return the cement slurry to the surface , establish the wellhead, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com