Radial well volume fracturing method

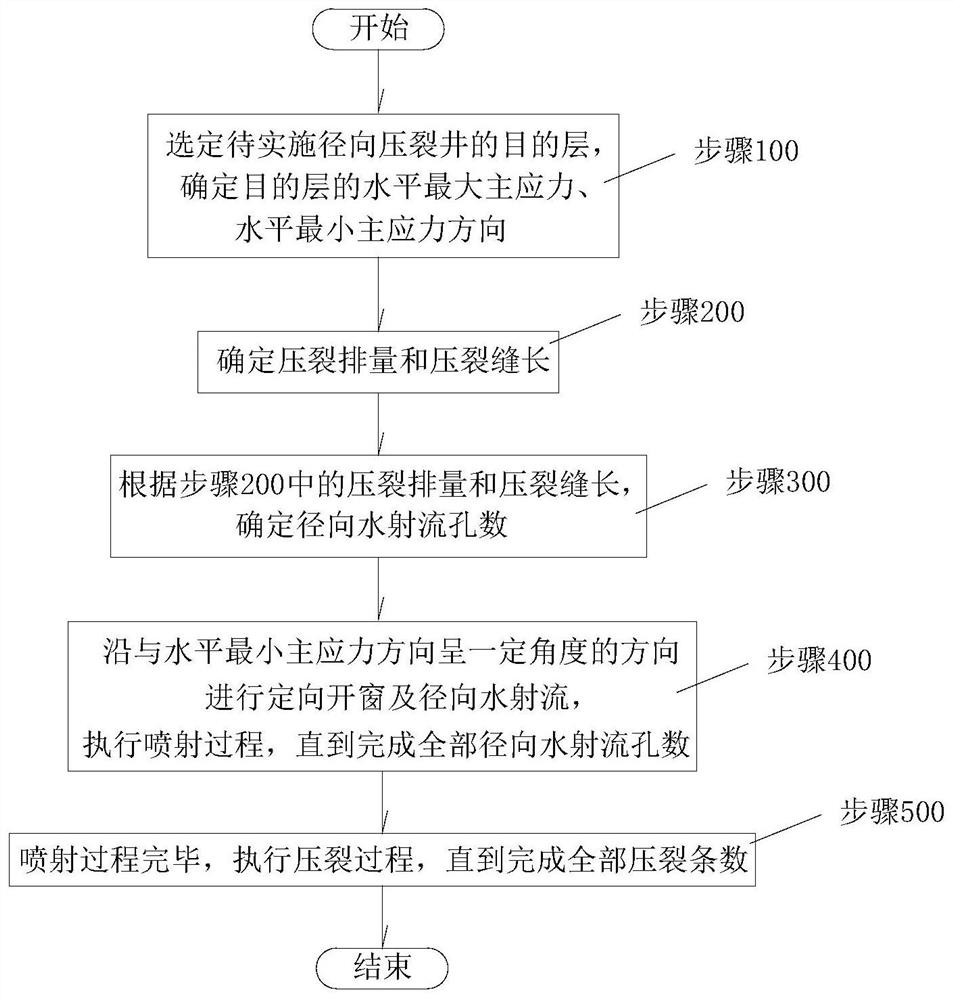

A volume fracturing and radial fracturing technology, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of simple fracturing process, producing oil and gas reserves, and expanding the affected area of fractures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] In this example, there are many remaining reserves among wells in the Shahe Formation reservoir in a certain block, and Well A is selected as the experimental well for the radial well volume fracturing experiment. The target layer of Well A is Shahezi Formation, the depth of the oil layer is 2000-2026m, and the thickness of the oil layer is 26m. The specific process includes the following:

[0054] First, for the Shahezi Formation core in Well A, stress testing methods such as core differential strain method and wave velocity anisotropy method were used in the experiment to obtain the horizontal maximum principal stress direction and horizontal minimum principal stress direction of the target layer. The stress test method is not the focus of the present invention, so it will not be repeated here. The directions of the horizontal maximum principal stress are 90° and 270°. Since the direction of the horizontal maximum principal stress is perpendicular to the direction of...

Embodiment 2

[0064] In this embodiment, there are many remaining reserves in the direction of 20° and 170° in the B well of Yingcheng group reservoir in a certain oil field block, and radial well volume fracturing is carried out in order to fully develop these reserves. The depth of the oil layer is 2610-2619m, and the thickness of the oil layer is 9m. The results of previous in-situ stress studies show that the directions of the horizontal maximum principal stress are 95° and 275°. Since the direction of the horizontal maximum principal stress is perpendicular to the direction of the horizontal minimum principal stress, the directions of the horizontal minimum principal stress are 5° and 185°.

[0065] The specific process includes the following:

[0066] Considering that the thickness of the target layer is 2610-2619m, the porosity of the reservoir is 14%, the permeability is 8md, the fracture pressure is 45MPa, and the fracture height is 15m. The crack is 90m long.

[0067] Secondly, ...

Embodiment 3

[0075] In this example, the conventional fracturing of new wells in Yingcheng group in an oilfield block has low production capacity after conventional fracturing, which cannot meet the requirements of economical and effective development. Therefore, the volume fracturing experiment of radial wells is carried out on the new well C. The depth of the oil layer is 2500-2518m, and the thickness of the oil layer is 18m. The results of previous in-situ stress studies show that the directions of the horizontal maximum principal stress are 80° and 260° on average. Since the direction of the maximum horizontal principal stress is perpendicular to the direction of the minimum horizontal principal stress, the directions of the minimum horizontal principal stress are 350° and 170°.

[0076] The specific process includes the following:

[0077] Considering that the thickness of the target layer is 2500-2518m, the porosity of the reservoir is 8%, the permeability is 1md, the fracture pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com