Feed scattering and charging device

A feeding device and feed technology, applied in fish farming, application, animal husbandry, etc., can solve the problems of limited throwing area, affecting feeding effect, falling off, etc., and achieve the effects of simple structure, labor saving, and easy production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

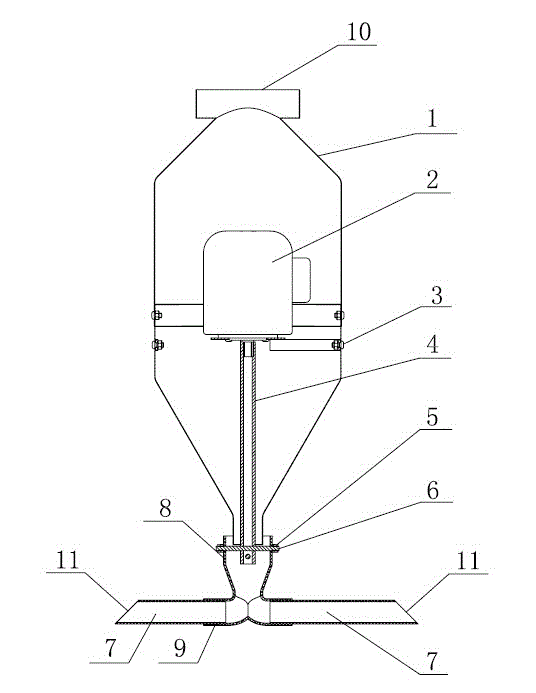

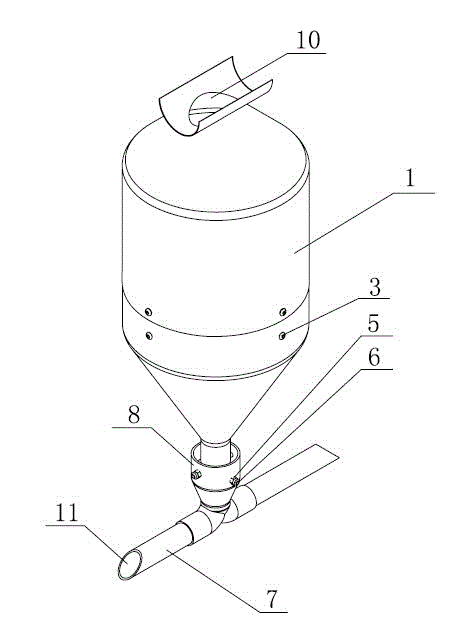

[0023] Such as Figure 1-2 As shown, a feed throwing and feeding device includes a fixed material cylinder 1, a motor 3 installed inside the fixed material cylinder 1, and a sprinkler assembly installed at the bottom of the fixed material cylinder 1. The top of the fixed material cylinder 1 is provided with a feeding port 10 , The motor 3 is fixed inside the fixed barrel 1 through the hexagon head screw bolt 3 .

[0024] The sprinkling assembly is connected to the motor 3 through the transmission shaft 4; the sprinkling assembly includes two sprinkling barrels 7 and a three-way pipe fitting; Socketed on the outside of the transmission shaft 4 and connected by the screw rod 6 and the hexagonal lock nut 5, the sleeve joint 9 is socketed with the throwing cylinder 7; the throwing assembly rotates with the rotation of the motor 3 and the transmission of the drive shaft 4, and the rotation movement The central axis is the transmission shaft 4.

[0025] The junction of the two sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com