Synchronal rotary oil-gas multiphase pump

An oil and gas mixing pump and oil cylinder technology, applied in the field of power machinery, can solve the problems of waste of social resources, environmental pollution, reduction of single well production, etc., and achieve the effects of saving electric energy, improving single well production, and low operating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

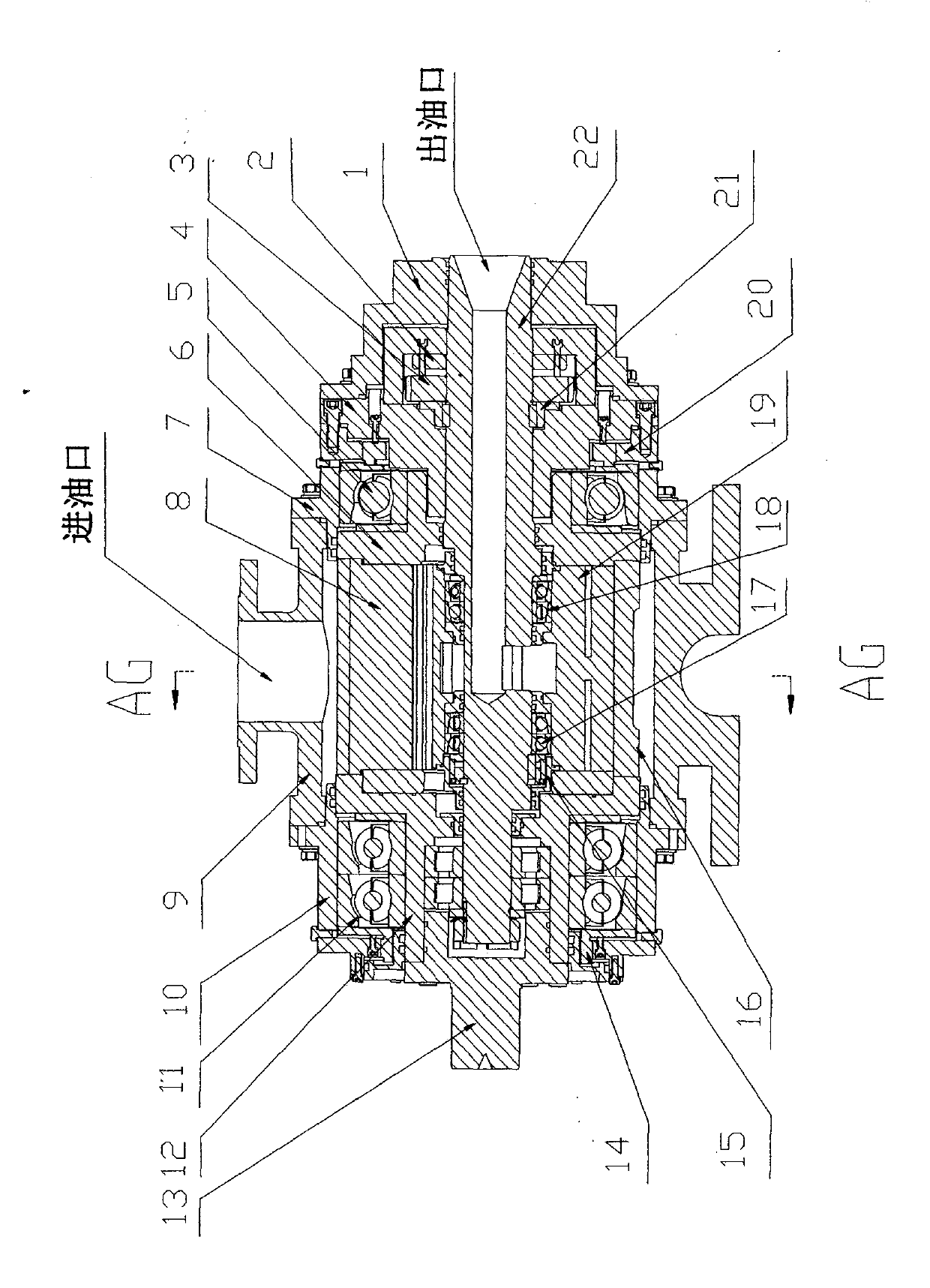

[0032] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

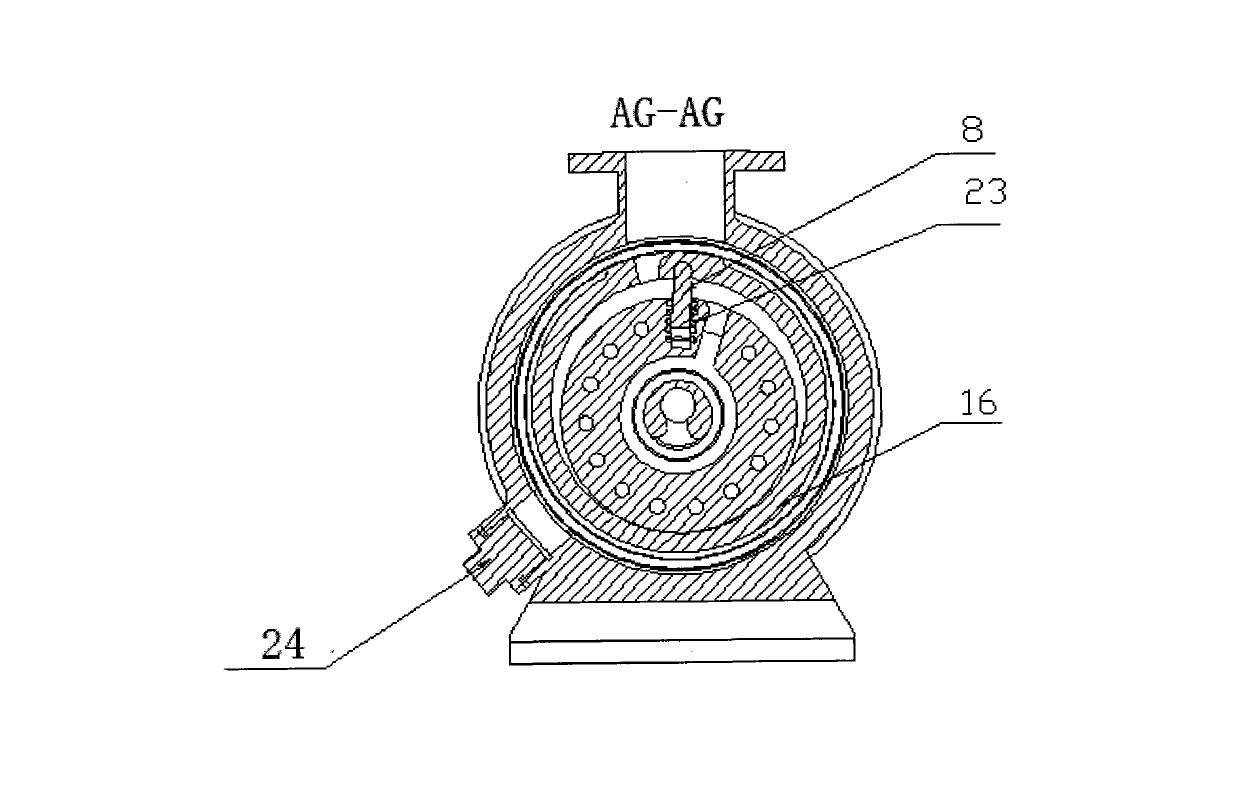

[0033] refer to Figure 1-Figure 2 , a synchronous rotary oil-gas mixed delivery pump, in which a front end bearing seat 10, a rear end bearing seat 7, an oil cylinder 16, a rotor 19, a slide plate 8, a left end cover 12, a right end cover 6, an eccentric shaft 22 and adjustment The adjustment part is composed of key 21, adjustment nut 2; 3, rear end adjustment 4, rear end adjustment nut 20, front end adjustment nut 14, double half card structure 15, housing 9 is provided with sewage device 24, housing 9 It forms an oil storage cavity with the front bearing seat 10 and the rear bearing seat 7; the oil cylinder 16 is connected with the left end cover 12 and the right end cover 6 through screws to form the main transmission shaft part, and the main transmission shaft part is installed on the front end bearing seat 10 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com