Fracturing method for improving gravel penetration rate of conglomerate and glutenite reservoirs

A glutenite and gravel penetration rate technology is applied in the field of hydraulic fracturing, which can solve the problems of low hydraulic fracture penetration rate and high hydraulic fracture surface roughness, and achieves the advantages of improving fracturing effect, increasing gravel penetration rate, and simple construction and operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

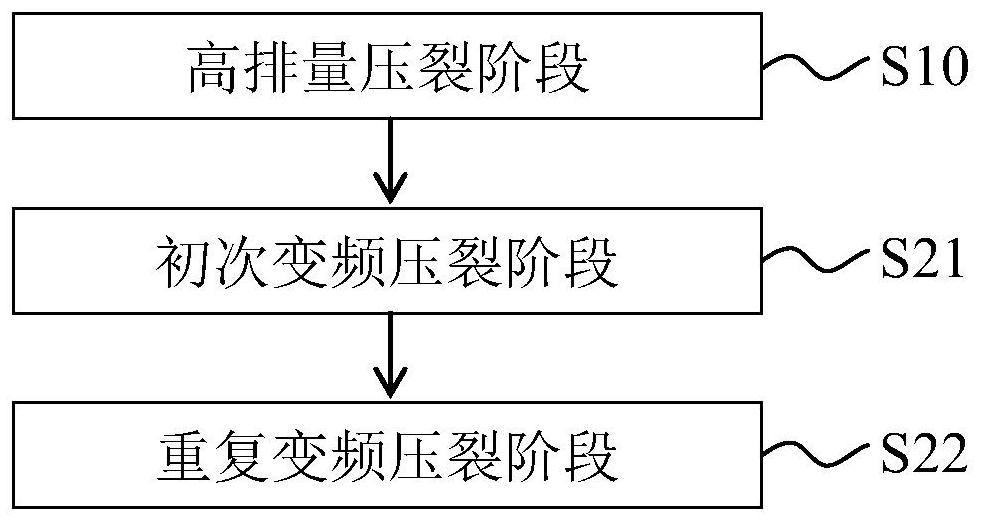

[0031] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. In the description of the present invention, unless otherwise specified, "multiple times" means two or more times.

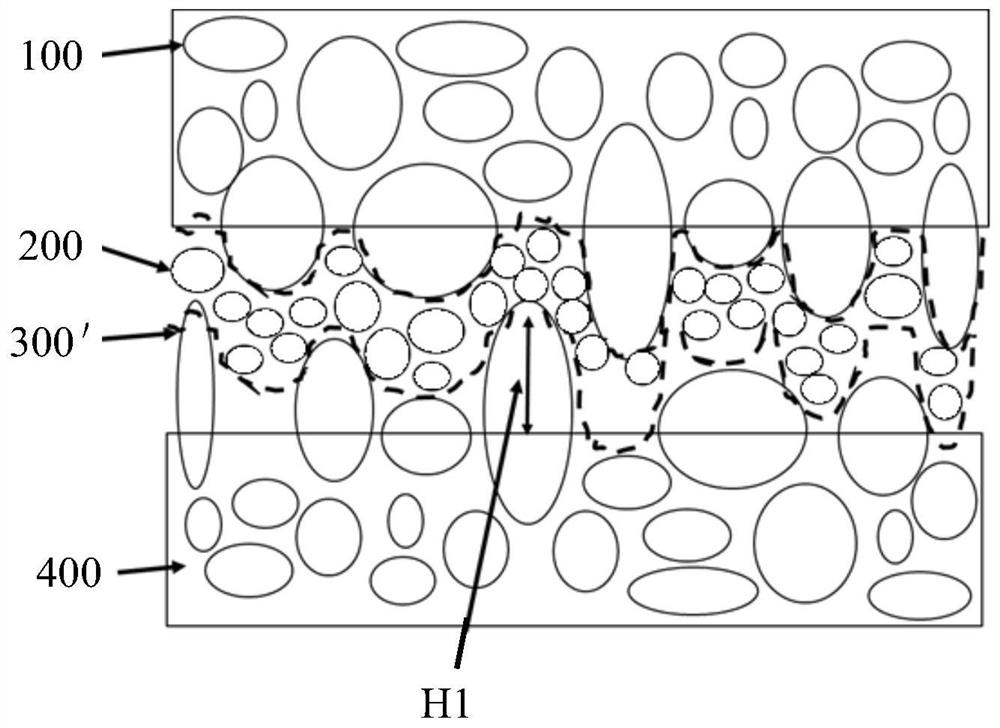

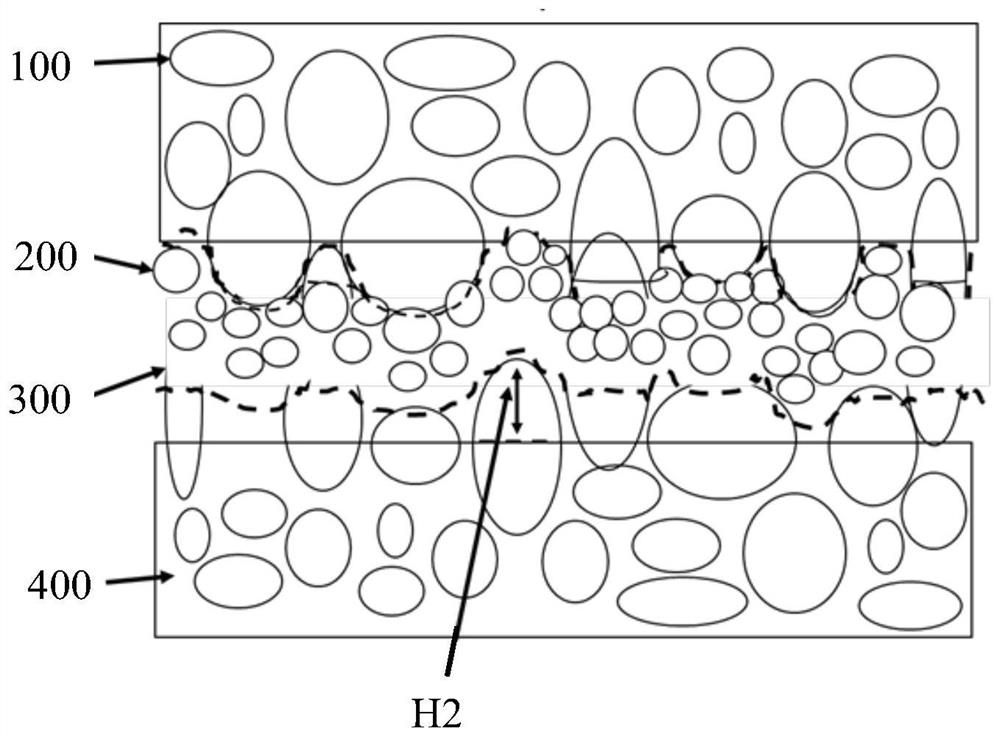

[0032] See figure 1 , when conventional fracturing technology is applied to conglomerate and glutenite reservoirs, the gravel penetration rate of hydraulic fractures is low, and the roughness of fracture surfaces is high. figure 1 The two dotted lines in the figure represent the fracture surface 300', and the arrow pointed to by H1 represents the undulation of the fracture surface 300'. The high undulation of the fracture surface 300' affects the settlement, migration and laying of the proppant 200, making the single well The output appears to be high in the early stage of production and sharply decreased in the lat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com