Method for regulating well drilling liquid granularity distribution

A particle size distribution and drilling fluid technology, applied in drilling composition, chemical instruments and methods, earthwork drilling and production, etc., can solve the problems that affect the plugging effect and do not consider the impact, so as to increase the production of single well and reduce the filtration rate. The effect of loss and good reservoir

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

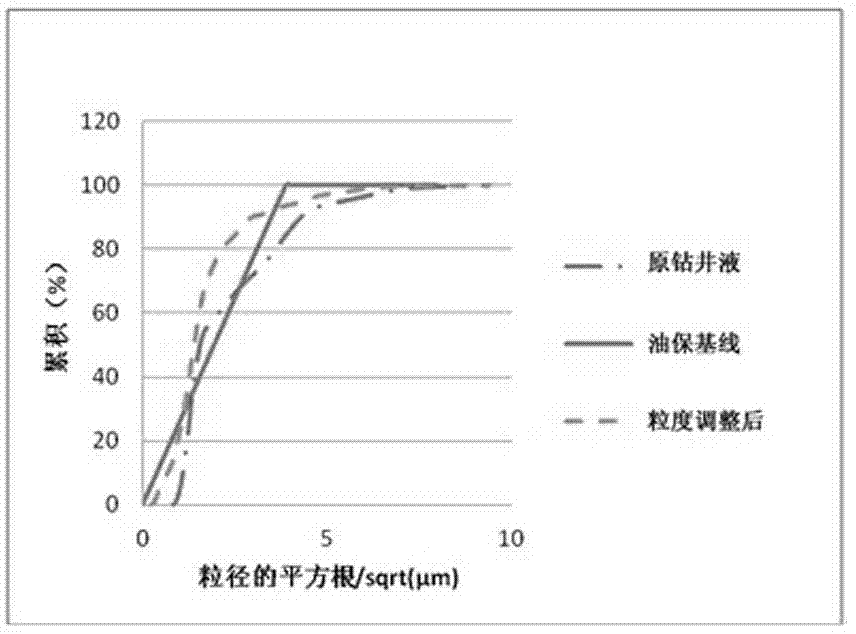

[0025] Secondly, using the particle size distribution data of the drilling fluid and the plugging and shielding agent, the following mathematical model is used to draw the square root coordinate diagram of cumulative volume % to particle size,

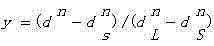

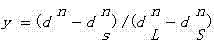

[0026]

[0027] In the formula, y is the particle fraction content smaller than the particle size d; d is any particle size, unit μm; n is the model parameter; d L is the maximum particle size in the particle system, unit μm; d S is the smallest particle size in the particle system, in μm;

[0028] Third, according to the maximum pore throat diameter D of the reservoir 90 , (100%, (D 90 ) 1 / 2 ) and the origin as the oil conservation baseline;

[0029] Fourth, change the particle size or / and ratio of the drilling fluid or / and the blocking and shielding agent so that the cumulative volume % of the drilling fluid and different blocking and shielding agents to the square root of the particle size curve is closer to the oil conservat...

Embodiment 2

[0032] Example 3:

Embodiment 3

[0034] The particle size distribution data of drilling fluid and plugging and shielding agent were measured by laser particle size analyzer.

[0035] Example 4:

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com