Method for increasing length of tight reservoir hydrofracturing effective prop fracture

A technology for hydraulic fracturing and tight reservoirs, applied in the field of oil and gas field exploration and development, can solve the problems of low single well production and low fracture conductivity, so as to increase single well production, expand fracture support volume, and improve sand laying profile Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

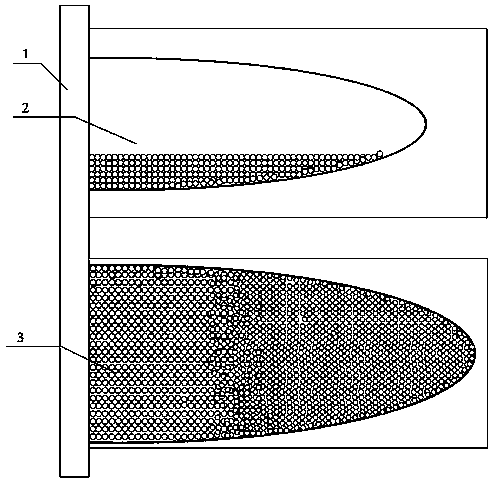

[0024] In order to solve the problems of existing hydraulic fracturing fractures, such as the length of effective support fractures, low fracture conductivity, and low single well production. The present invention provides as figure 1 Shown is a method for increasing the effective length of hydraulic fracturing of tight reservoirs. The present invention can maximize the length of effective supporting fractures of hydraulic fracturing of tight reservoirs, improve the conductivity of fractures, improve the sanding profile, expand Fracture support volume, improve single well production.

[0025] A method for increasing the effective support fracture length of hydraulic fracturing in tight reservoirs, the specific steps are:

[0026] Step 1: before the hydraulic fracturing of the tight reservoir, the cable transmission firepower is used to perforate;

[0027] Step 2 Select ultra-low-density proppant during the hydraulic fracturing of tight reservoirs, and use sluggish water frac...

Embodiment 2

[0032] Based on the basis of Example 1, in this example, before the first fracturing, cable transmission firepower perforation was used, and the spiral hole arrangement method was used. The length of the perforation section was 4 meters, and the hole density was 16 holes / m.

[0033] In the second step, the volume density of the ultra-low density proppant is 0.8.

[0034] The ultra-low density proppant is sintered at high temperature by bauxite, corundum sand and additives, and the mass ratio of the bauxite, corundum sand and additives is: the proportion of bauxite is 75-80 %, the proportion of corundum sand is 10-15%, and the additive is 5-10%, wherein the additive is bentonite or manganese ore, and the ultra-low density proppant is a spherical double-layer structure with a hollow center.

[0035] The slick water fracturing fluid in the second step has a viscosity of 2-5 centipoise, a core damage rate of <15%, a drag reduction rate of ≥60%, and an interfacial tension of ≤0.25...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com