Full-bore well completion fracturing method for low-permeability reservoir sidetracking well

A full-bore, low-permeability technology, applied in the direction of wellbore/well components, earthwork drilling, production fluid, etc., can solve the problems of low construction efficiency, stuck pipe, and unprotected old casing, so as to reduce the The number of trips of the lower fracturing drilling tool, the improvement of production degree, and the effect of increasing single well production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

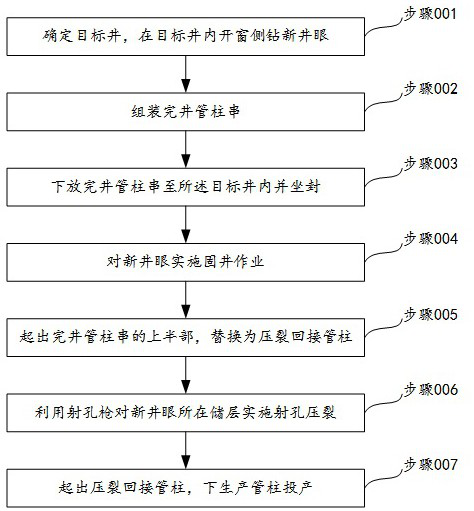

[0049] This embodiment relates to a full bore well completion and fracturing method for sidetracking wells in low permeability reservoirs, such as figure 1 , including the following steps:

[0050] Step 001. Determine the target well, and open a window in the target well to sidetrack a new wellbore;

[0051] Step 002. Assemble the completion string;

[0052] Step 003. Lower the completion string into the target well and set;

[0053] Step 004. Carry out well cementing operation to the new wellbore;

[0054] Step 005. Pull out the upper half of the completion string and replace it with a fracturing tieback string;

[0055] Step 006. Using a perforating gun to perform perforation and fracturing on the reservoir where the new wellbore is located;

[0056] Step 007. Pull out the fracturing tie-back string, lower the production string and put it into production.

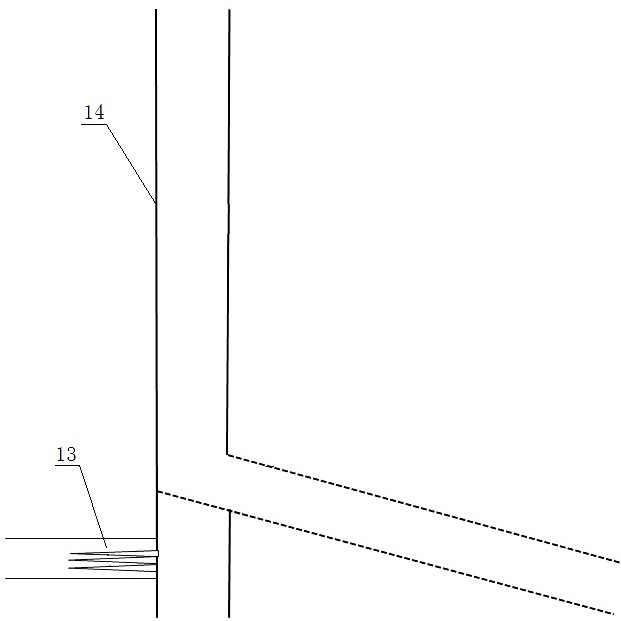

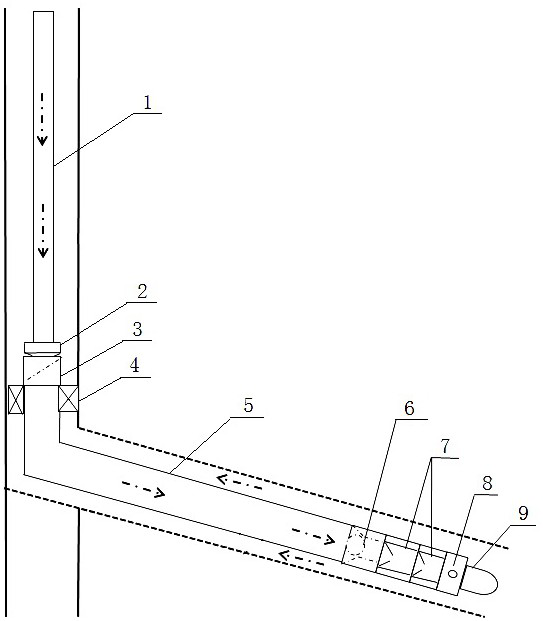

[0057] see figure 2 , which shows the target well, where the straight well section is the old wellbore, and the ...

no. 2 approach

[0062] This embodiment relates to a full bore well completion and fracturing method for sidetracking wells in low permeability reservoirs, such as figure 1 , including the following steps:

[0063] Step 001. Determine the target well, and open a window in the target well to sidetrack a new wellbore, specifically including:

[0064] S101. Select the oil well drilled in the early stage of oil well production as the target well;

[0065] S102. Sidetracking the borehole wall of the target well to form a new wellbore, and the new wellbore is connected to the remaining oil-enriched area and avoids the waterline.

[0066] Most of the oil wells in domestic oil fields are drilled in the initial stage of production. The wells are drilled with 5-inch and a half casings (outer diameter ø139.7mm, inner diameter ø124.3mm), and then sealed with cement slurry between the formation well wall and the casing. well cementing, such as figure 2 As shown, with the prolongation of the production ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com