T-shaped well group and method for exploiting non-diagenetic natural gas hydrates

A technology for hydrate and natural gas, applied in the fields of fluid extraction, coal gasification, and earth-moving drilling, etc., can solve the problems of poor wellbore stability, unstable wellbore, and high risks in the mining process, and achieve increased stability and well control safety, guaranteeing The effect of marine environmental safety, improving single well production and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

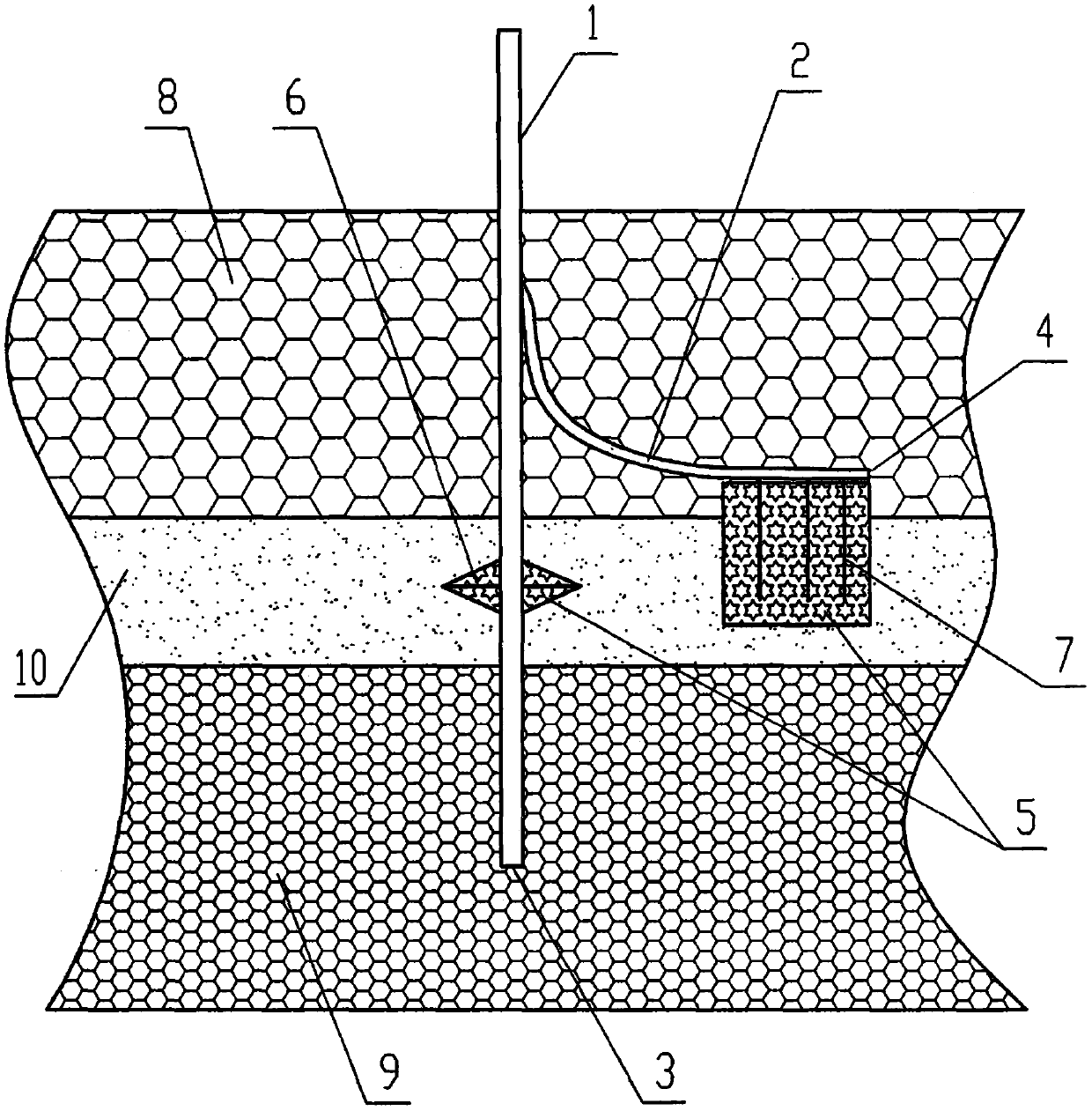

[0031] like figure 1 As shown, the T-shaped well group includes a vertical well 1 and a first horizontal well 2 sharing a wellhead, all of which are completed with casing. The vertical well target 3 of the vertical well 1 is located in the second stable formation 9 below the reservoir 10, and the distance from the vertical well target 3 to the reservoir 10 is 260 meters (the distance from the seabed to the reservoir 10 is 500 meters); the first horizontal well The target point 4 of the horizontal well of 2, the build-up section, the build-up section, the stabilizing section and the horizontal section are all located in the first stable formation 8 above the reservoir 10, and the length of the horizontal section is 400 meters; the vertical well 1 and the first horizontal well 2 are equipped with a fracturing sand control layer 5, the vertical well fracturing 6 of the vertical well 1 is a horizontal fracture, and the half-length of the vertical well fracturing 6 is 80 meters; th...

Embodiment 2

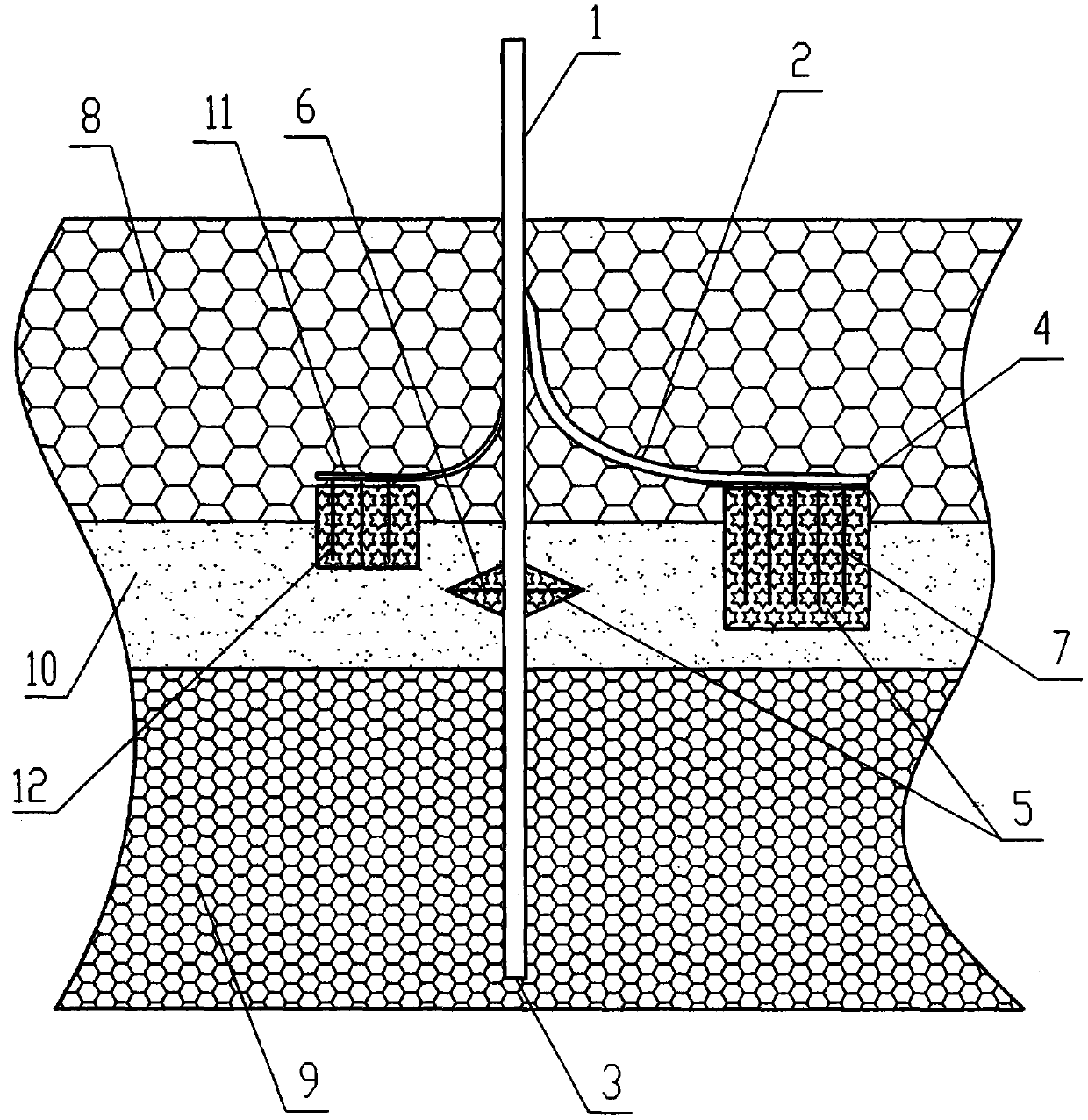

[0040] like figure 2As shown, the T-shaped well group includes a vertical well 1, a first horizontal well 2 and a second horizontal well 11 sharing one wellhead, all of which are completed with casing. The vertical well target 3 of the vertical well 1 is located in the second stable formation 9 below the reservoir 10, and the distance from the vertical well target 3 to the reservoir 10 is 480 meters (the distance from the seabed to the reservoir 10 is 800 meters); the first horizontal well The target point 4 of the horizontal well 2, the build-up section, the build-up section, the stabilizing section and the horizontal section are all located in the first stable formation 8 above the reservoir 10, and the length of the horizontal section is 1000 meters; the water in the second horizontal well 11 The target point of the flat well, the build-up section, the build-up section, the stabilizing section and the horizontal section are all located in the first stable formation 8 above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com