Performance test device and method for projection objective lens based on mask plate

A technology of projection objective lens and testing device, which is applied in testing optical performance, photo-engraving process exposure device, photography, etc., can solve the problems of uncertainty of the actual optical axis of the objective lens, unusability, etc., to reduce the difficulty of splicing, reduce the requirements, and reduce the measurement accuracy. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

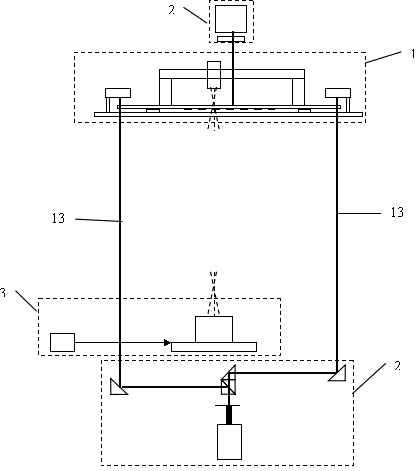

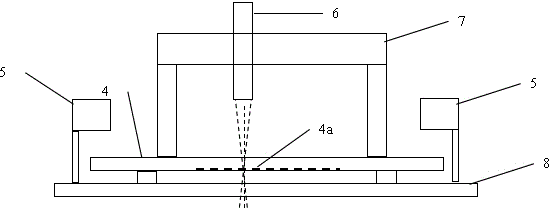

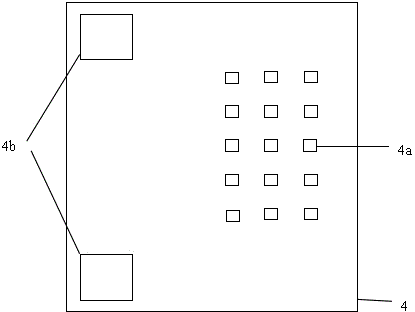

[0044] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0045] The present invention provides a mask-based projection objective lens performance test device and a test method, which can achieve the following three improvements compared with the current testing technology: 1) It can determine whether the object image plane of the objective lens is ideal in spatial position Conjugate, and can test to obtain the deviation; 2) Since the reference measurement is used, the influence of the mask surface shape, mark processing and manufacturing errors, standard wavefront errors, and inherent systematic errors in the measurement components on the measurement accuracy can be eliminated , so the measurement accuracy of the basic performance of the objective lens has been improved; 3) To measure the absolute telecentricity of the objective lens, the measurement method is simple and the accuracy is high.

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com