Ultra-carbon connecting tube jet drilling horizontal well system and jet drilling method

A horizontal well and jet drilling technology, which is applied to drilling equipment and methods, liquid/gas jet drilling, drilling equipment, etc., can solve the problems of complex downhole problems, high pollution, and a lot of waste, and achieve the reduction of environmental protection level , reduce the viscosity of crude oil and save the total investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

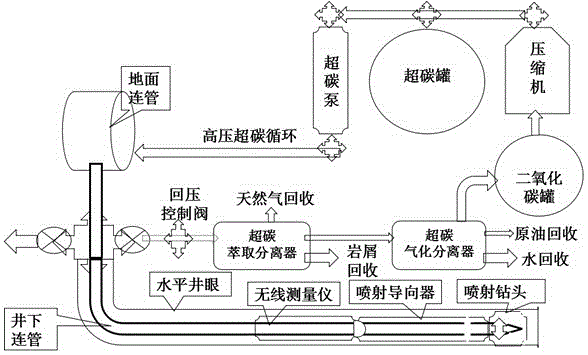

[0048] like figure 1 as shown, figure 1 It is a flow chart of the ultra-carbon continuous jet drilling horizontal well system provided in Example 1 of the present invention.

[0049] This embodiment discloses a super carbon continuous jet drilling horizontal well system, including a super carbon closed separation circulation unit and a super carbon continuous jet drilling unit, wherein,

[0050] The super-carbon airtight separation circulation unit is set on the ground to recover the downhole return produced by the super-carbon jet drilling unit during the jet drilling process, from which it is separated and processed to obtain supercritical carbon dioxide and then exported to the super-carbon jet drilling unit The unit specifically includes a back pressure control device, a super-carbon extraction separator, a super-carbon gasification separator, a carbon dioxide tank, a compressor, a super-carbon tank and a super-carbon pump connected in sequence through pipelines.

[0051...

Embodiment 2

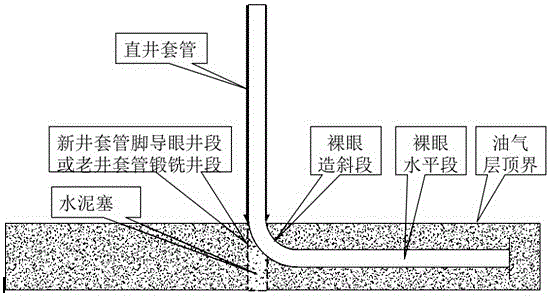

[0081] like Figure 5 as shown, Figure 5 Plan view of a single fishbone horizontal well for ultra-carbon continuous jet drilling provided in Example 2 of the present invention.

[0082] In this embodiment 2, for a single fishbone horizontal well with ultra-carbon continuous jet drilling, the ultra-carbon continuous jet drilling horizontal well system described in embodiment 1 is adopted, and the ultra-carbon circulation separation steps are the same as step S1 in embodiment 1. The difference lies in S2: using supercritical carbon dioxide jet to drill a single fishbone horizontal well, which specifically includes the following steps:

[0083] S301. For new drilling, put casing and cement on the top of the oil layer in advance, drill the casing accessories and oil and gas layer pilot holes and log the well, or open the casing at the top of the oil and gas layer of the old well, or forge and mill it into an open hole.

[0084] S302. Seal the pilot hole section of the new well ...

Embodiment 3

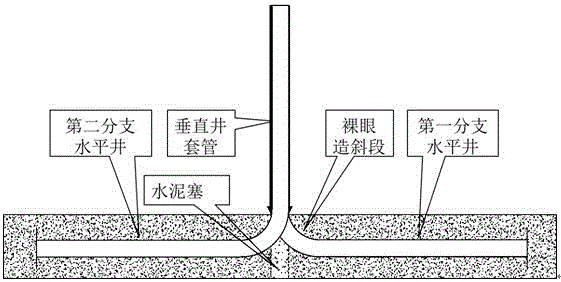

[0092] like Image 6 as shown, Image 6 The plan view of the double fishbone horizontal well provided by the ultra-carbon jet-drilling jet drilled in Example 3 of the present invention.

[0093] In this embodiment 3, the super carbon jet drilling horizontal well system described in embodiment 1 is adopted for super carbon jet drilling double fishbone horizontal wells, and the super carbon circulation separation steps are the same as step S1 in embodiment 1 , the difference lies in S2: using supercritical carbon dioxide jetting to drill double fishbone horizontal wells, specifically including the following steps:

[0094] S401. For new drilling, put casing and cement on the top of the oil layer in advance, drill the casing accessories and the pilot hole of the oil and gas layer and log the well, or open the casing at the top of the oil and gas layer of the old well, or forge and mill it into an open hole.

[0095] S402. Seal the pilot hole section of the new well or the forgi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com