Well completion technique for efficiently controlling pressure and retaining water cone of horizontal well

A horizontal well and water slowing technology, applied in wellbore/well components, directional drilling, and production of fluids, etc., can solve the problem that the bottom water coning has no great effect, The problems of limited water coning effect, etc., can achieve the effect of improving single well production, no environmental pollution, and convenient implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

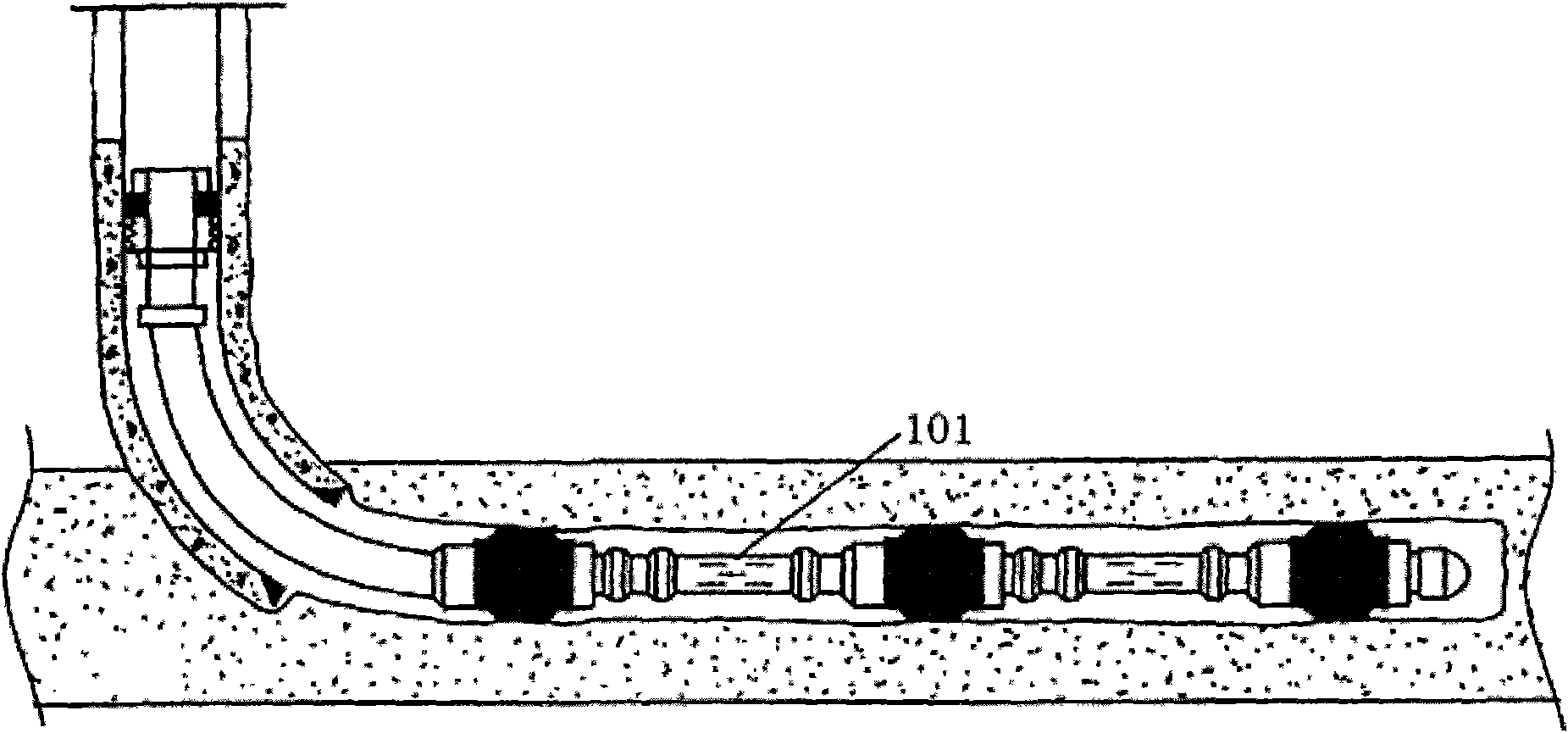

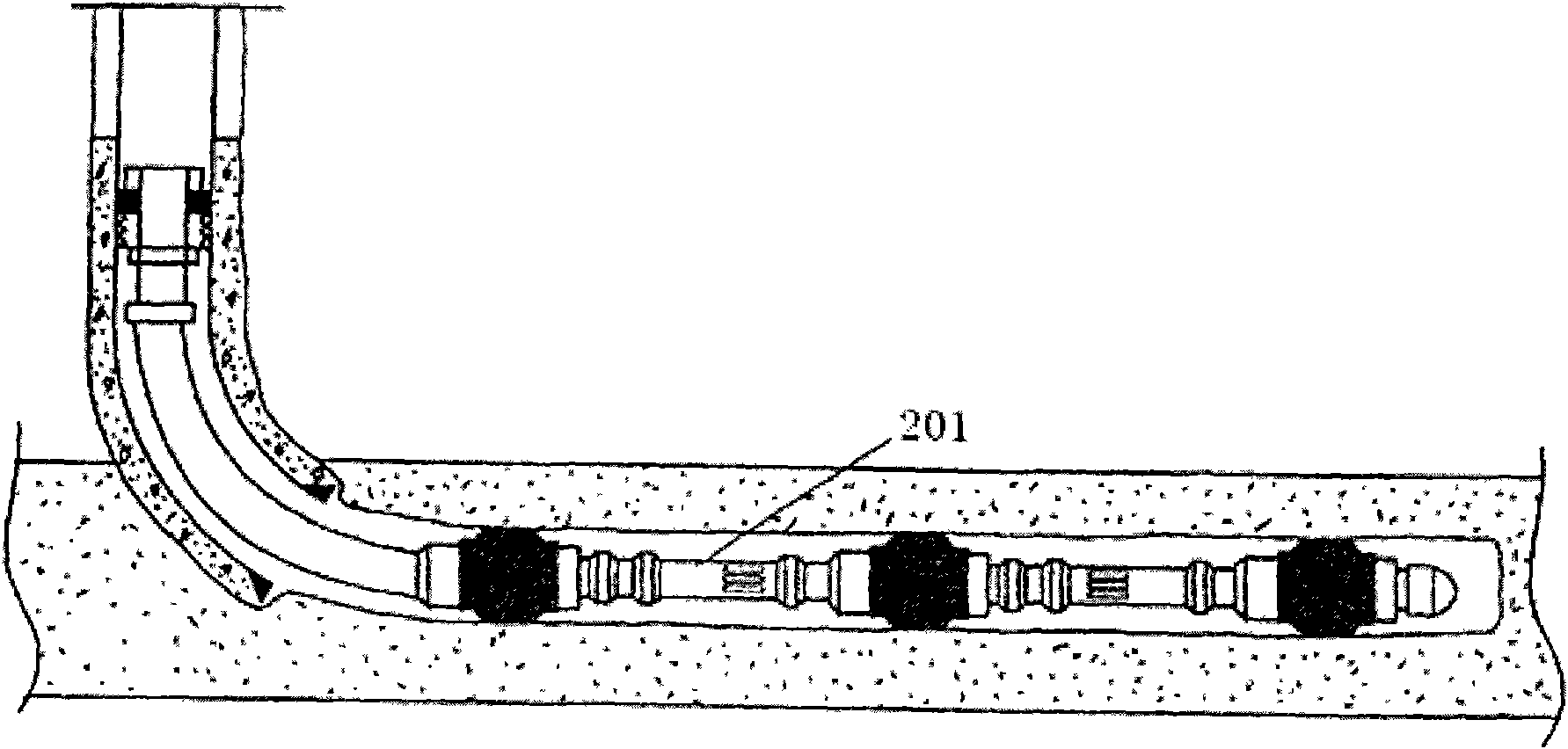

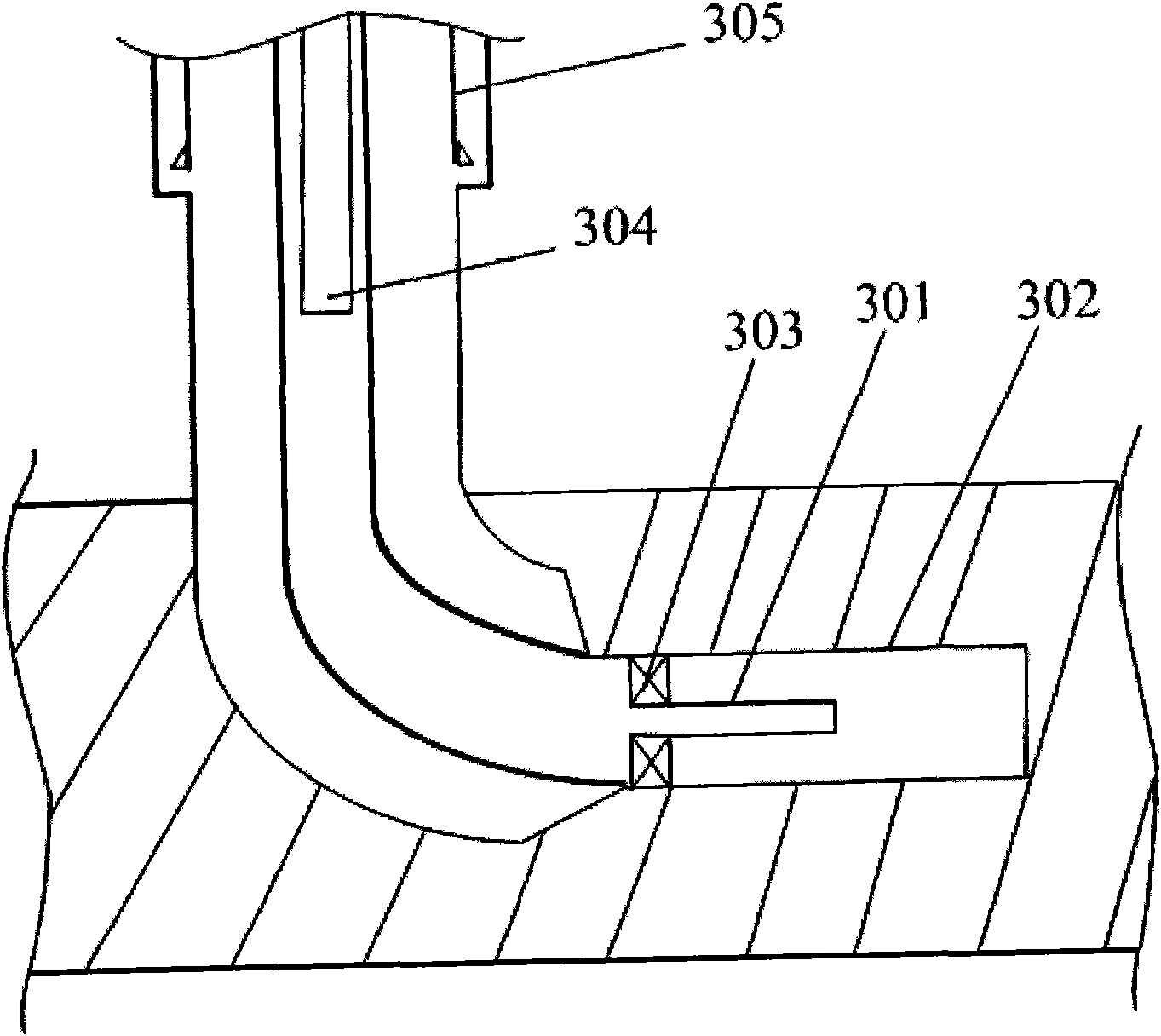

[0022] The structural schematic diagram of the high-efficiency pressure-controlled and slow-water cone horizontal well completion device of the present invention is as follows: image 3 As shown, it is used for the development of oil and natural gas, including a horizontal well and a vertical well that are connected, and a production oil pipe 304 and a casing 305 for outputting crude oil are arranged in the vertical well. A screen pipe 302 for supporting the open-hole well can be arranged in the horizontal well, and a non-coupling oil pipe 301 for controlling pressure and slowing water is arranged in the screen pipe 302, preferably, the non-coupling oil pipe 301 is arranged in the middle of the horizontal well. A packer 303 is arranged between the uncoupling oil pipe 301 and the screen pipe 302 to seal the annular space between the screen p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com