Multi-section fracturing horizontal well liquid production profile test string

A liquid production profile and test tube technology, which is applied in wellbore/well components, production fluid, earthwork drilling and production, etc., can solve the problems of interlayer interference and difficulty in testing liquid production profile, so as to improve test accuracy and avoid stratum interfering and enhancing oil recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

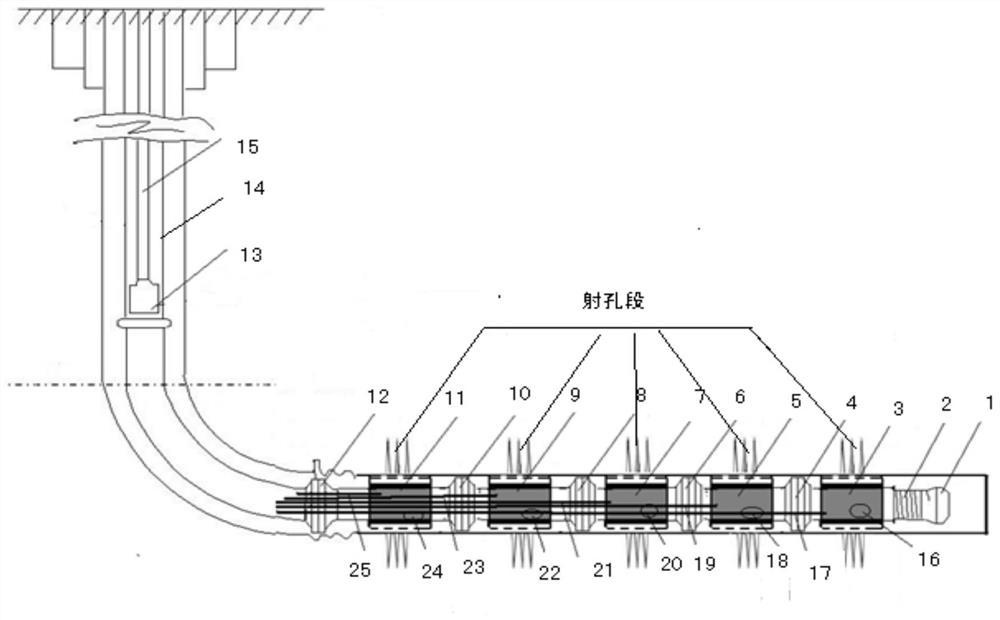

[0044] A multi-stage fracturing horizontal well fluid production profile test pipe string includes five single-flow hole pipes, five packers and five single-flow channels.

[0045] The five single flow eye tubes are respectively the first single flow eye tube 3 , the second single flow eye tube 5 , the third single flow eye tube 7 , the fourth single flow eye tube 9 and the fifth single flow eye tube 11 .

[0046] The five packers are the first packer 4 , the second packer 6 , the third packer 8 , the fourth packer 10 and the fifth packer 12 .

[0047] The five single-flow channels are respectively the first single-flow channel 17 , the second single-flow channel 19 , the third single-flow channel 21 , the fourth single-flow channel 23 and the fifth single-flow channel 25 .

[0048] The first tracer 16 is set in the first single flow eye tube 3, the second tracer 18 is set in the second single flow eye tube 5, the third tracer 20 is set in the third single flow eye tube 7, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com