Insulation aging test device used for converter high voltage pulse equipment

A technology of insulation aging and test device, applied in the direction of measuring device, measuring electrical variables, instruments, etc., can solve the problems of accelerated aging test of insulating materials, avoid interlayer interference, reduce the number of windings, and reduce the distortion of pulse square wave waveform Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

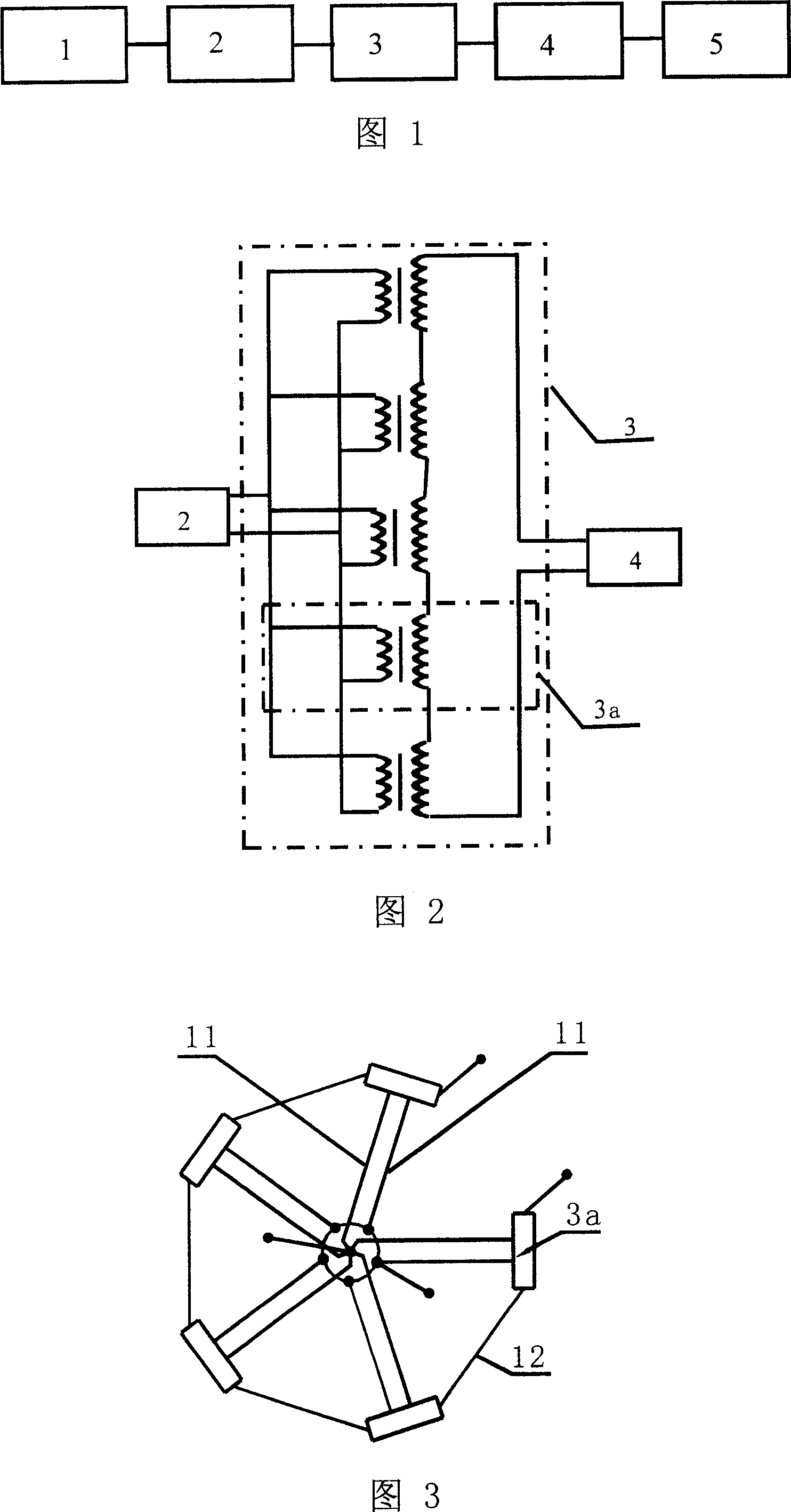

[0020] Figure 1 shows that a specific embodiment of the present invention is: an insulation aging test device for frequency conversion high-voltage pulse equipment, including an isolation transformer 1 connected to a commercial frequency power supply, and a pulse generator connected to the output terminal of the isolation transformer 1 2, the output end of the pulse generator 2 is connected to the wire in the insulating sleeve 4 of the oven 5. The specific way in which the output end of the pulse generator 2 is connected to the wire in the insulating sleeve 4 of the oven 5 is as follows: the output end of the pulse generator 2 is connected to the primary side of the high-frequency step-up transformer 3, and the secondary side of the high-frequency step-up transformer 3 is connected to the insulating sleeve 4 wires are connected. The high-frequency step-up transformers 3 are: four high-frequency step-up transformers 3 that are alternately connected with operating frequencies of...

Embodiment 2

[0027] This embodiment is basically the same as Embodiment 1, except that the high-frequency step-up transformer 3 is composed of two transformers 3a.

Embodiment 3

[0029] This embodiment is basically the same as Embodiment 1, except that the high frequency step-up transformer 3 is composed of 10 transformers 3a.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com