Downhole intelligent controlling type expansion packer

A packer and intelligent control technology, applied in the directions of sealing/packing, wellbore/well components, wellbore/well valve devices, etc. Achieve the effect of curbing sand production, reducing downhole accidents and simplifying the sealing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

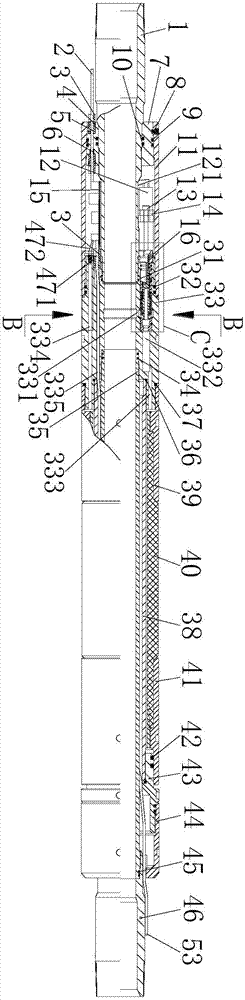

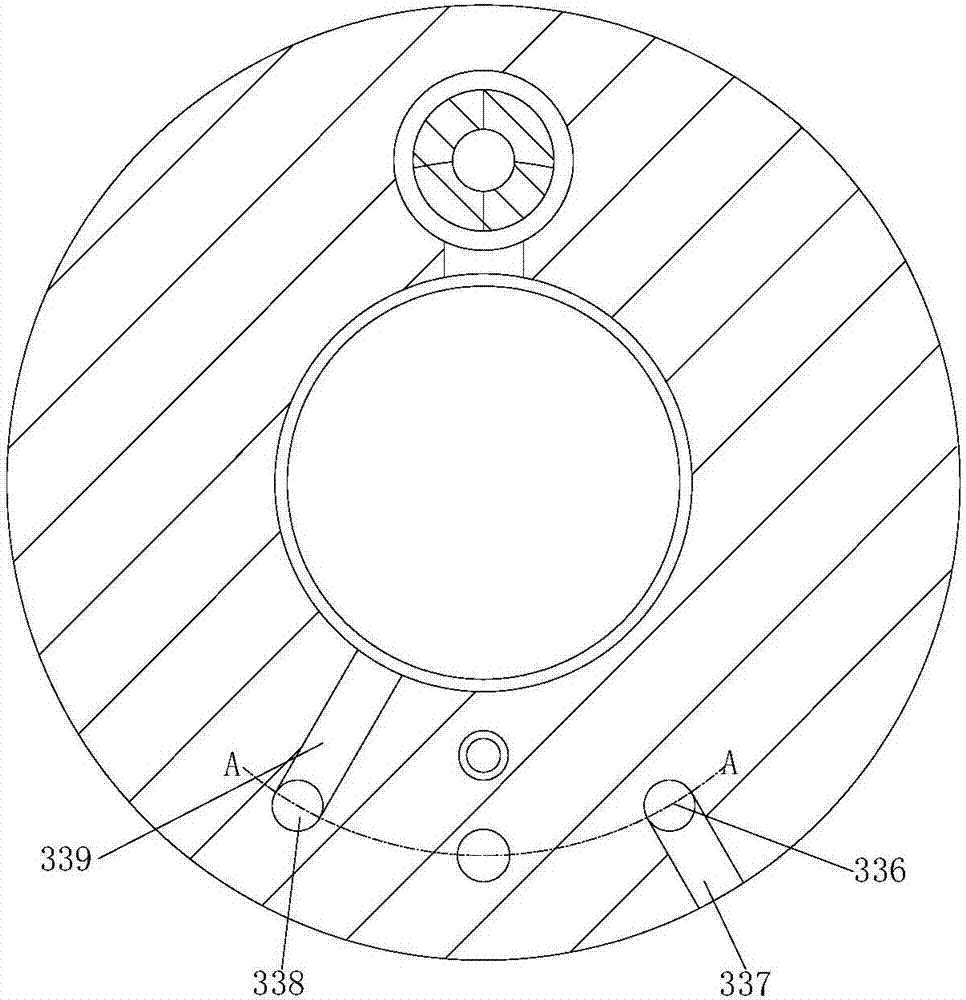

[0021] see Figure 1-4, in an embodiment of the present invention, a downhole intelligent control expansion packer includes an upper joint 1 and a lower joint 46, the upper joint 1 is fixedly connected with an intelligent control board 15, the intelligent control board 15 is connected to the first connecting line 472, the second The second connection line 542, the third connection line 552, the electric switch connection line 121, the upper steel pipe cable 2 and the lower steel pipe cable 53 are connected without defects, the upper joint 1 and the piston head 7 are threaded and sealed, and the piston head 7 is connected to the sealing body 33 Threaded sealing connection, the piston head 7 is provided with a third seal ring 9 and a fourth seal ring 10, the piston head 7 is sealed with the bin shell 11, the bin shell 11 is threaded with the detent pin 8, and the detent pin 8 is connected with the piston head 7 pin connection, the upper steel pipe cable 2 is worn in the eccentri...

Embodiment 2

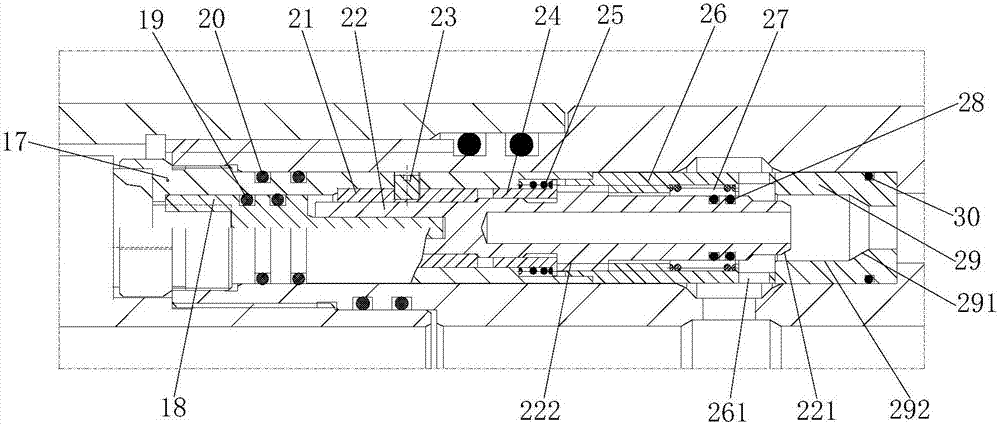

[0024] see Figure 5 , the lower end of the power sleeve 18 is inserted into the upper end of the rotating shaft 48, the rotating shaft 48 is provided with a liquid inlet and outlet hole 481, one side of the rotating shaft 48 is provided with a mouth valve seat 49, and the mouth valve seat 49 is provided with a valve ball 50, the valve ball 50 The lower spring 51 is connected to the support 52 , and the support 52 is provided with a middle hole 521 .

[0025] Operation process: use oil pipes to connect with other tools and run into the well in sequence. The cables of each tool are connected without defects, and they are connected to the wellhead to connect with the ground control system to keep the power supply and communication normal; 49 The built-in valve ball 50 is always closed under the action of the lower spring 51. If the pressure difference formed between the oil jacket and the pipe is greater than the elastic force of the lower spring 51, the packer will be seated, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com