Bicavity oil pump

An oil pumping and oil field technology, applied in the direction of pumps, pumps with flexible working elements, liquid variable capacity machines, etc., to achieve high output and avoid interlayer interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

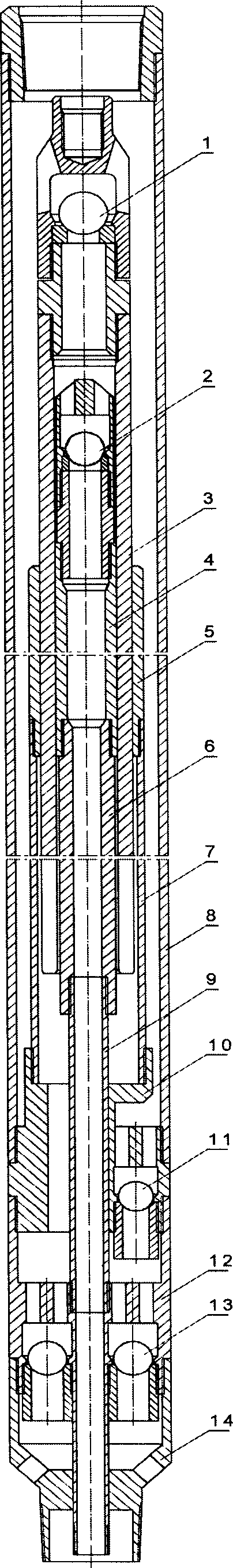

[0009] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings. As shown in the figure, it consists of upper oil outlet valve 1, upper oil inlet valve 2, plunger pump barrel 3, small plunger 4, large pump barrel 5, upper connecting pipe 6, extension pipe 7, outer pipe 8, and lower connecting pipe 9 , oil outlet valve joint 10, lower oil outlet valve 11, oil inlet valve joint 12, lower oil inlet valve 13, and tail joint 14 to form. The lower part of the upper oil outlet valve 1 is connected to the upper part of the plunger pump cylinder 3 . The lower part of the large pump barrel 5 is connected to the extension pipe 7, the lower part of the upper oil inlet valve 2 is connected to the upper part of the small plunger 4, the lower part of the small plunger 4 is connected to the upper connecting pipe 6, and the plunger pump barrel 3 is located between the large pump barrel 5 and the small plunger 4 , The outer wall of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com