Method for using rotating-stream tray in phase-phase polyethylene process and rotating-stream tray device

A swirl plate, polyethylene technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems affecting the fluidization gas velocity and fluidization quality of the bed, and improve the space-time yield and the quality of the fluidization. Stability of plant operation, effect of reducing pressure drop and increasing flexibility of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

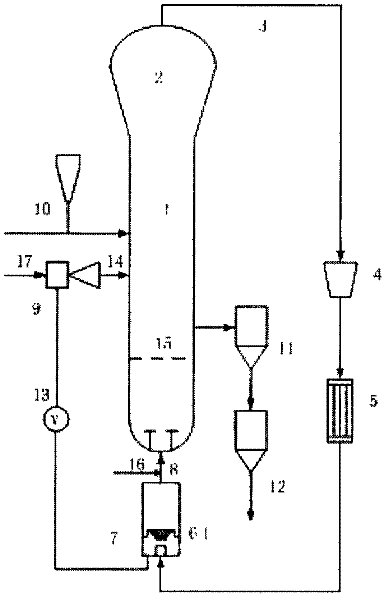

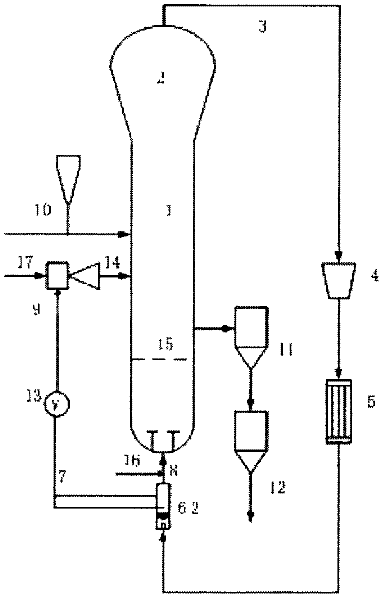

[0044] exist figure 1 The linear low-density polyethylene (LLDPE) is produced in the fluidized bed polymerization reactor using the external swirl plate separator shown. Under the action of the Z-N catalyst system, the polymerization reaction temperature is 88 ° C, the pressure is 2.1 MPa, and the reactor is empty. Tower speed 0.67m / s. The diameter of the external swirl plate separator is 3.2m, the outer diameter of the blade is 2.2m, the diameter of the blind plate is 0.7m, the elevation angle of the blade is 25°, and the number of blades is 16. The circulating gas flow in pipeline 3 includes hydrogen, nitrogen, methane, ethane, ethylene, hexene and hexane, the pressure is 2.1 MPa, and the temperature is 86°C. Contain 25% condensed liquid in the recirculating gas flow from condenser 5, the liquid phase is hexene and hexane, and the density is 615.2kg / m 3 , the gas phase density is 28.0kg / m 3 . Through the external swirl plate separator, the condensate content in the pipe...

Embodiment 2

[0046] exist figure 1 The linear low-density polyethylene (LLDPE) is produced in the fluidized bed polymerization reactor using the external swirl plate separator shown. Under the action of the Z-N catalyst system, the polymerization reaction temperature is 87 ° C, the pressure is 2.1 MPa, and the reactor is empty. Tower speed 0.70m / s. The diameter of the external swirl plate separator is 2.5m, the outer diameter of the blade is 2.0m, the diameter of the blind plate is 0.6m, the elevation angle of the blade is 20°, and the number of blades is 20. The circulating gas flow in pipeline 3 includes hydrogen, nitrogen, methane, ethane, ethylene, and isopentane, with a pressure of 2.1 MPa and a temperature of 84°C. Contain 35% condensate in the circulating airflow from the condenser 5, the liquid phase is isopentane, and the density is 650.0kg / m 3 , the gas phase density is 33.0kg / m 3 . Through the external swirl plate separator, the content of condensate in the pipeline 7 can r...

Embodiment 3

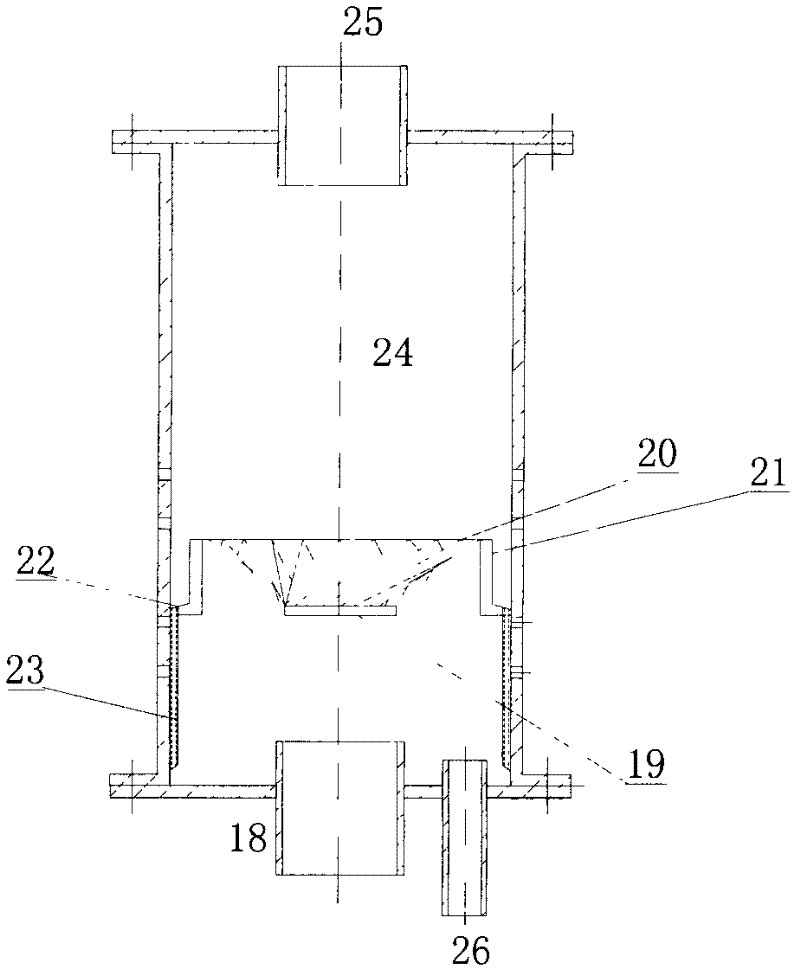

[0048] exist figure 1 The linear low density polyethylene (LLDPE) is produced in the fluidized bed polymerization reactor using the external swirl plate separator shown. Under the action of the Z-N catalyst system, the polymerization reaction temperature is 85 ° C, the pressure is 2.3 MPa, and the reactor is empty. Tower speed 0.75m / s. The diameter of the external swirl plate separator is 2.5m, the outer diameter of the blade is 2.0m, the diameter of the blind plate is 0.6m, the elevation angle of the blade is 25°, and the number of blades is 18. Install a wire mesh demister on the top of the external swirl plate separator, with a wire diameter of 0.5mm and a void ratio of 98%. The circulating gas flow in pipeline 3 includes hydrogen, nitrogen, methane, ethane, ethylene, hexene and hexane, the pressure is 2.3MPa, and the temperature is 82°C. Contain 45% condensed liquid in the recirculating gas flow from condenser 5, the liquid phase is hexene and hexane, and the density is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com