Feather keratin-based biopolymer external application material and preparation method thereof

A feather keratin and biopolymer technology is applied to the preparation of feather keratin-based biopolymer external coating materials, the fields of rapid sterilization and anti-inflammatory for acute wounds and external dressing materials, and can solve the problems of restricting gelatin materials, insufficient thermal stability, difficult to control, etc. problems, to avoid wound fluid, eliminate wound odor, good antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

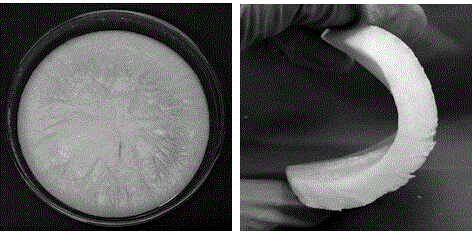

[0047] Dissolve 5 g of feather keratin in 80 mL of 2 mol / L sodium hydroxide solution to obtain a feather keratin solution; dissolve 10 g of gelatin in 50 mL of distilled water, then add it to the feather keratin solution, and mix under stirring at room temperature Uniform; then add 0.8 g of 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride as a condensation agent, stir for 1 h, then add 0.5 g of N-hydroxysuccinimide as a condensation agent Auxiliary, adjust the pH value of the system to 5, stir for 2 h, then add 1.5 g sorbitol as a plasticizer, continue stirring for 1 h, after the reaction is completed, dialyze with distilled water for 24 h under dark conditions, then vacuum freeze After drying, the feather keratin grafted gelatin external dressing material is obtained.

[0048] The water absorption of the external application material reaches 37%, and its swelling rate reaches 440%. The swelling rate in saline solution reaches 475%, and the amount of saline solution...

Embodiment 2

[0050] Dissolve 1 g of feather keratin in 20 mL of 0.8 mol / L urea solution to obtain a feather keratin solution; dissolve 4 g of gelatin in 40 mL of distilled water, then add it to the feather keratin solution, and mix well under stirring at room temperature; Add 0.2 g of 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride as a condensation agent, stir for 1 h, then add 0.1 g of N-hydroxysuccinimide as a condensation aid , adjusted the pH value of the system to 6, stirred for 1.5 h, then added 0.5 g glycerol as a plasticizer, and continued to stir for 1 h. After the reaction was completed, it was dialyzed with distilled water for 20 h under dark conditions, and vacuum freeze-dried to obtain feathers. Keratin grafted gelatin external dressing material.

[0051] The appearance and properties of the external coating material are similar to Example 1.

Embodiment 3

[0053] Dissolve 10 g of feather keratin in 100 mL of 8 mol / L potassium hydroxide solution to obtain a feather keratin solution for use. Dissolve 50 g of gelatin in 200 mL of distilled water, add feather keratin solution, mix well under stirring at room temperature, then add 2 g of 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride as a condensation After stirring for 2.5 h, add 1 g of N-hydroxysuccinimide as a condensation aid, adjust the pH value of the system to 7, stir for 3 h, then add 5 g of maltitol as a plasticizer, continue stirring for 1 h, and react After the end, under the condition of avoiding light, dialyze with distilled water for 24 h, and then dry to obtain feather keratin grafted gelatin external coating material.

[0054] The appearance and properties of the external coating material are similar to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com