Optimization method of oil refinery hydrogen system and application thereof

An optimization method and refinery technology, applied in data processing application, prediction, calculation, etc., can solve problems such as limited benefit and simultaneous optimization of light hydrocarbon components in hydrogenation units, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

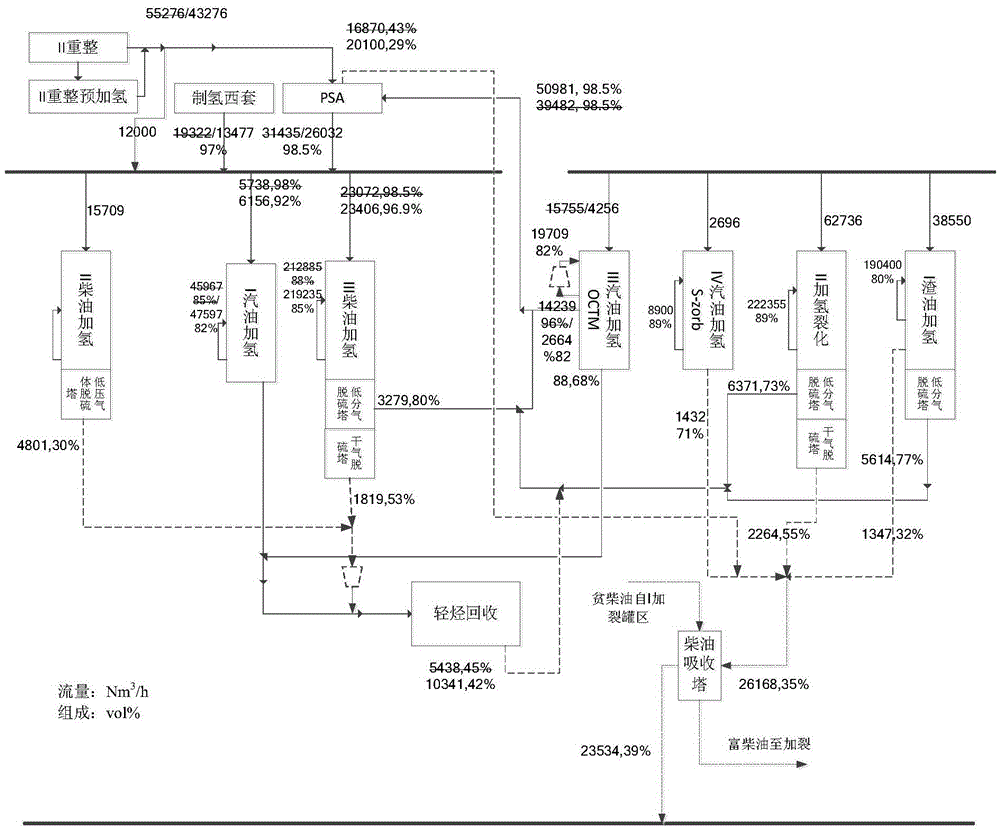

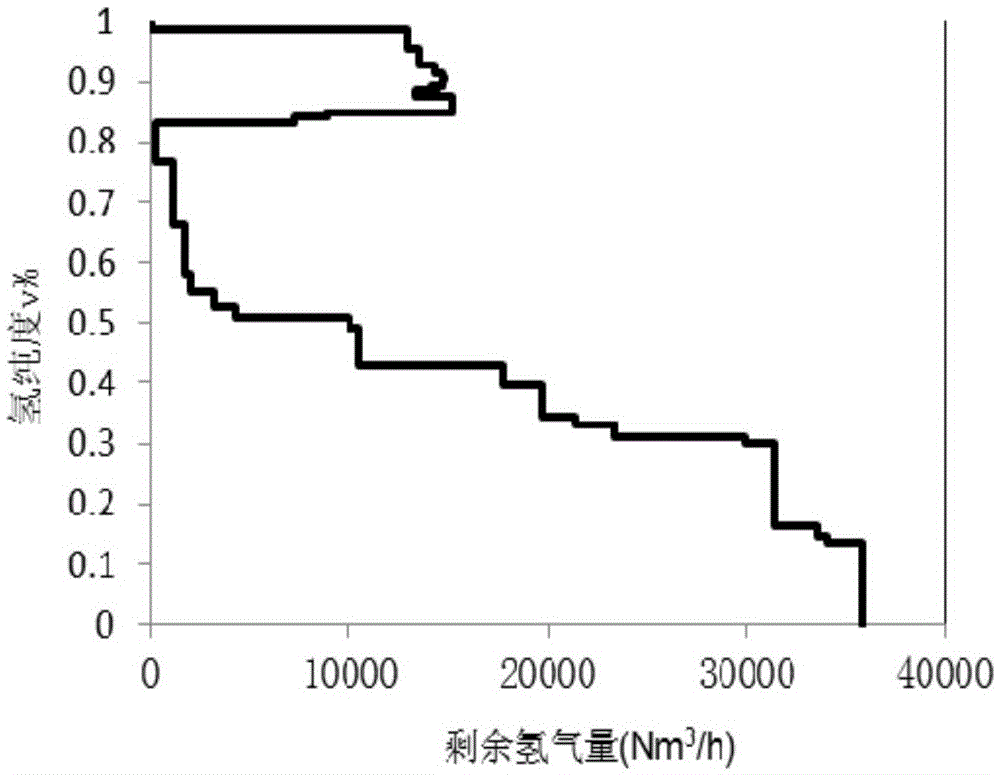

[0088] After upgrading the quality of oil products in a refinery, the scale of hydrogen consumption is 242562Nm 3 / h, the cost of hydrogen consumption has increased significantly, but the utilization rate is low. The refinery carried out optimization work for the purpose of saving hydrogen consumption, reducing hydrogen cost and increasing comprehensive income.

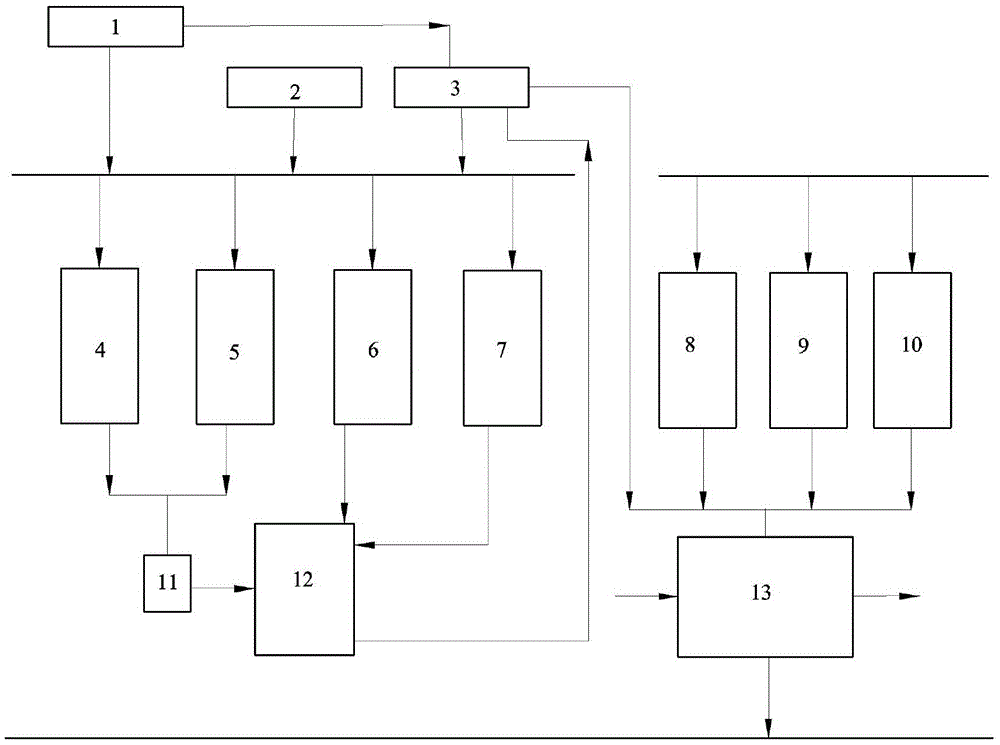

[0089] Hydrogen systems in refineries (e.g. figure 1 shown) includes a sequentially connected hydrogen supply system, hydrogen consumption system and gas recovery system;

[0090] The hydrogen supply system includes a parallel II hydrogen reforming unit 1, a hydrogen production unit 2 and a PSA unit 3, and the three transport hydrogen to the hydrogen pipeline network through the hydrogen delivery pipeline respectively; the II reforming hydrogen unit 1 also passes the reforming The hydrogen pipeline is connected with the PSA device 3;

[0091] The hydrogen consumption system includes parallel II diesel hydrogenation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com