Down-hole real-time adjustable throttling technology

An adjustable and technological technology, applied in the fields of production fluids, wellbore/well components, earth-moving drilling, etc., can solve the problems that the aperture of the throttle gas nozzle cannot be adjusted in real time, and the pressure and production cannot be adjusted in real time, so as to achieve real-time pressure and production. Adjustable, extend the whole production cycle, the effect of reliable and stable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The invention discloses a downhole real-time adjustable flow process, which includes the following four steps:

[0029] 1) Install a preset working cylinder;

[0030] 2) Put a preset downhole adjustable flow device;

[0031] 3) Adjust the preset downhole adjustable flow device;

[0032] 4) Salvage preset downhole adjustable flow device.

[0033] among them:

[0034] 1) Install the preset working cylinder

[0035] According to the formation pressure, formation temperature and test production, calculate the depth of the preset downhole adjustable flow device, and then install the preset downhole adjustable flow device at a certain depth of the downhole tubing string through the tubing thread. , Provide setting preparations for the release of preset downhole adjustable flow devices.

[0036] 2) Put in a preset downhole adjustable flow device

[0037] After the installation of the preset work is completed, when launching, use the well test wire belt to use the launch tool for the preset...

Embodiment 2

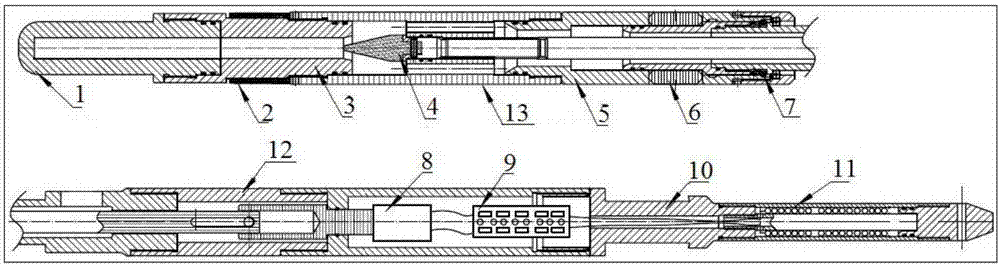

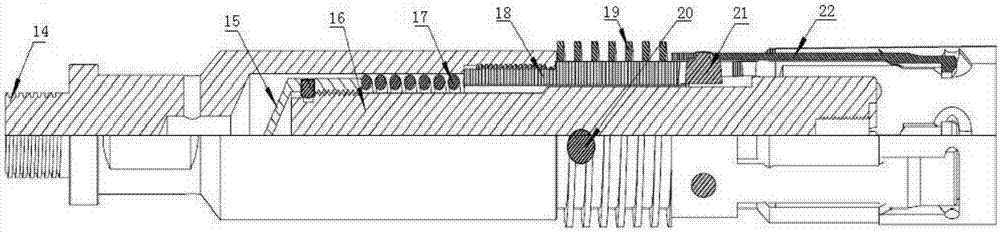

[0043] On the basis of Example 1, the preset working cylinder is composed of an integrally designed working cylinder upper joint, a working cylinder body, and a working cylinder lower joint. The inner surfaces of the working cylinder upper joint and the working cylinder lower joint are provided with threads. In connection with the well-entry tubing, the working cylinder body is provided with two grooves, and the two grooves 4 are respectively matched with the slips 6 and the rubber cylinder 2 of the preset downhole adjustable flow device.

[0044] The application of the present invention is as follows:

[0045] 1. Before putting the preset downhole adjustable flow device into the gas well, the upper joint of the working barrel and the lower joint of the working barrel should be threadedly connected with the well tubing, so that the prefabricated working barrel can be lowered to the predetermined well depth position through the tubing. The buckle type of the lower joint with the wor...

Embodiment 3

[0049] On the basis of the above-mentioned embodiment, the step 2) to release the preset downhole adjustable flow device is to use a release tool to perform the running, setting and anchoring of the preset downhole adjustable flow device.

[0050] The launching tool is composed of an integrated design of the launching tool body and an upper joint of the launching tool. The launching tool body is provided with a pin hole matching the signal receiver 11 of the preset downhole adjustable flow device. The joint is connected with the well test wire tool string through threads.

[0051] The specific applications of the delivery tool are as follows:

[0052] 1. First, before putting the preset downhole adjustable flow device into the gas well, the putting tool and the well test wire tool string should be well connected on the ground.

[0053] 2. After the launching tool is connected, connect the launching tool to the upper end of the preset downhole adjustable flow device through the launchi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com