Method and device for polymerization of olefins

An olefin polymerization and olefin technology, which is applied in the production of polyolefins and polyolefin copolymers, can solve the problems of complicated operation methods and high equipment investment, and achieve the effect of high separation efficiency, strong practical significance and application value, and increased flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1: (VLDPE)

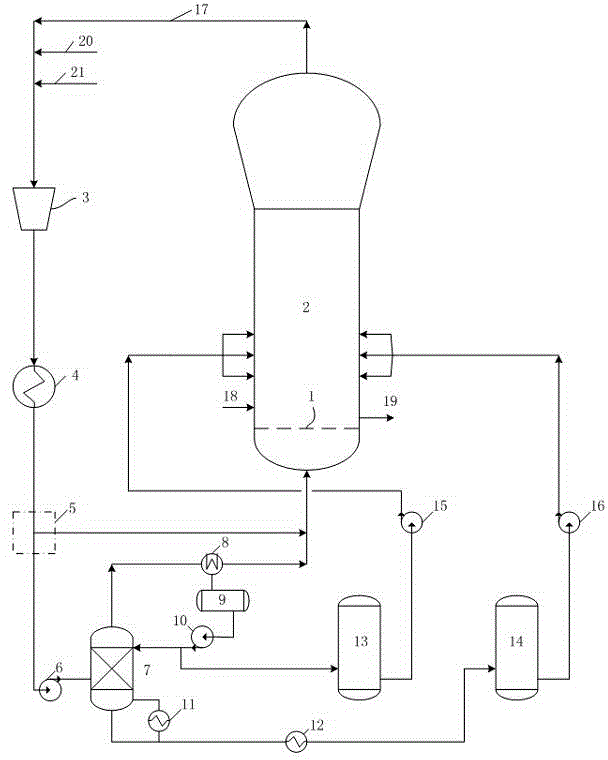

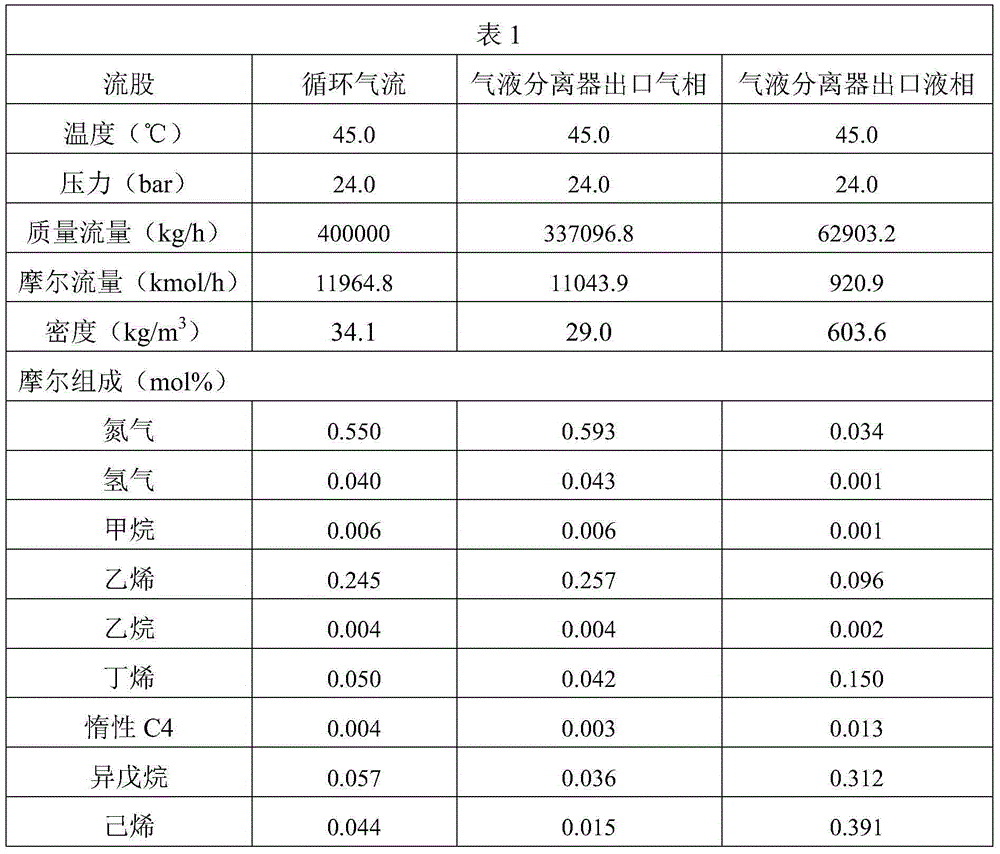

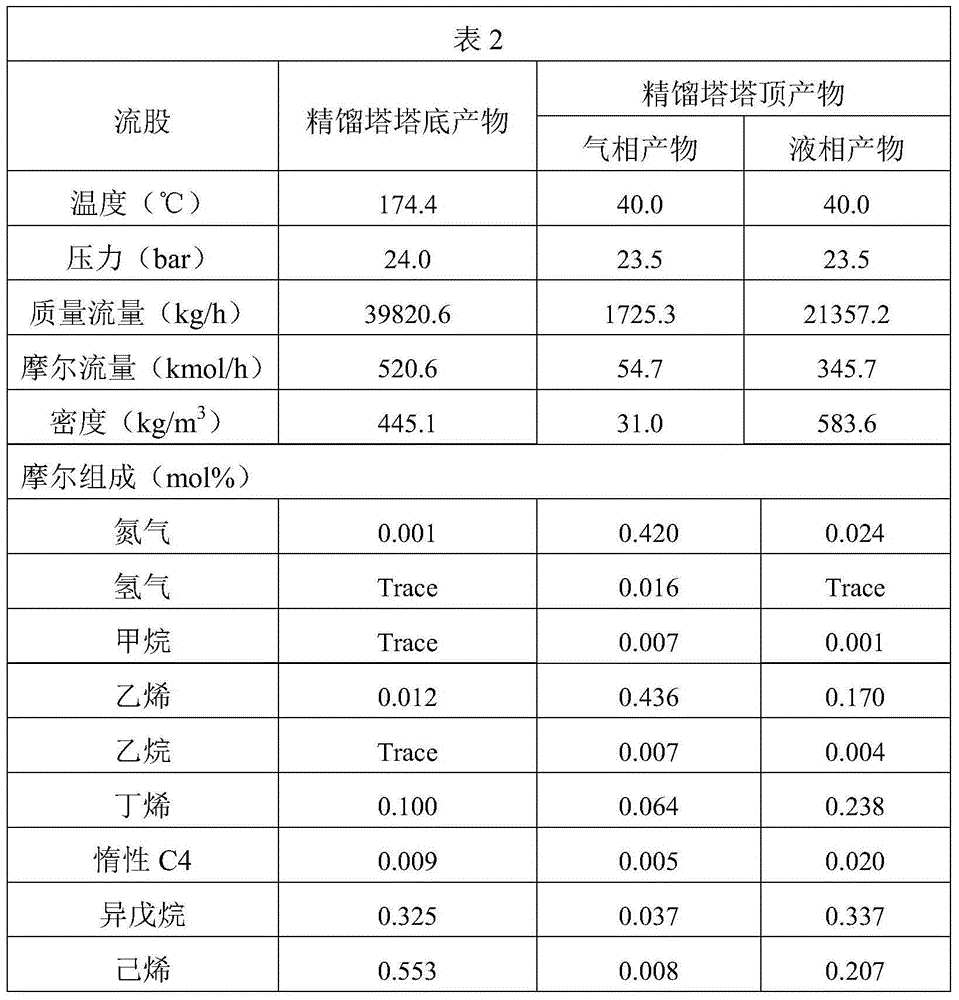

[0055] exist figure 1 The production of ultra-low density polyethylene (VLDPE) by an olefin polymerization method shown, under the action of the Z-N catalyst system, the polymerization reaction temperature is 80 ° C, the pressure is 2.3 MPa, and ethylene, butene, and hexene are reacted in a fluidized bed. Ternary copolymerization reaction occurs in the reactor, and the superficial velocity of the reactor is 0.61m / s. The circulating gas stream in pipeline 13 includes hydrogen, nitrogen, methane, ethane, ethylene, butene, inert C4, isopentane and hexene, the temperature is 81°C, and the pressure is 2.3MPa. The unreacted gas material is taken out from the top outlet of the reactor 2, enters the compressor 3 inlet with fresh polymerized monomers, chain transfer agents, and inert gas nitrogen, and then passes through the heat exchanger 4 (such as a fixed tube-sheet heat exchanger) , the circulating air flow is partially condensed, and the liquid mix...

Embodiment 2

[0062] Embodiment 2: (VLDPE)

[0063] exist figure 1 The production medium density polyethylene (VLDPE) of a kind of olefin polymerization method shown, under the effect of Z-N catalyst system, polymerization reaction temperature is 80 ℃, pressure 2.3MPa, in ethylene, butene, hexene in the fluidized bed reactor The three-way copolymerization reaction occurs inside, and the superficial velocity of the reactor is 0.57m / s. The circulating gas flow in pipeline 13 includes hydrogen, nitrogen, methane, ethane, ethylene, isopentane and hexene, the temperature is 80°C, and the pressure is 2.3MPa. The unreacted gas material is taken out from the top outlet of the reactor 2, enters the compressor 3 inlet with fresh polymerized monomers, chain transfer agents, and inert gas nitrogen, and then passes through the heat exchanger 4 (such as a fixed tube-sheet heat exchanger) , partial condensation of the circulating airflow occurs, and the liquid mixture accounts for 13.2wt% of the circula...

Embodiment 3

[0066] Embodiment 3: (LLDPE)

[0067] exist figure 1 The production of linear low-density polyethylene (LLDPE) in a kind of olefin polymerization method shown, under the action of Z-N catalyst system, the polymerization reaction temperature is 90 ℃, the pressure is 2.3MPa, and ethylene and hexene occur in the fluidized bed reactor. For binary copolymerization, the superficial velocity of the reactor is 0.65m / s. The circulating gas stream in pipeline 13 includes hydrogen, nitrogen, methane, ethane, ethylene, isopentane and hexene at a temperature of 90°C and a pressure of 2.3 MPa. The unreacted gas material is taken out from the top outlet of the reactor 2, enters the compressor 3 inlet with fresh polymerized monomers, chain transfer agents, and inert gas nitrogen, and then passes through the heat exchanger 4 (such as a fixed tube-sheet heat exchanger) , the circulating air flow is partially condensed, and the liquid mixture accounts for 20.0wt% of the circulating air flow. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| tensile yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com