Improvement of manner for introducing condensation agent into fluidised bed polymerisation reactor and device

A polymerization reactor and fluidized bed technology, which is applied in chemical instruments and methods, chemical/physical processes, etc., can solve problems such as fluidized bed fluid accumulation and streamline density increase, and achieve improved production capacity, strong practical significance and Application value, the effect of avoiding liquid accumulation at the bottom of the fluidized bed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

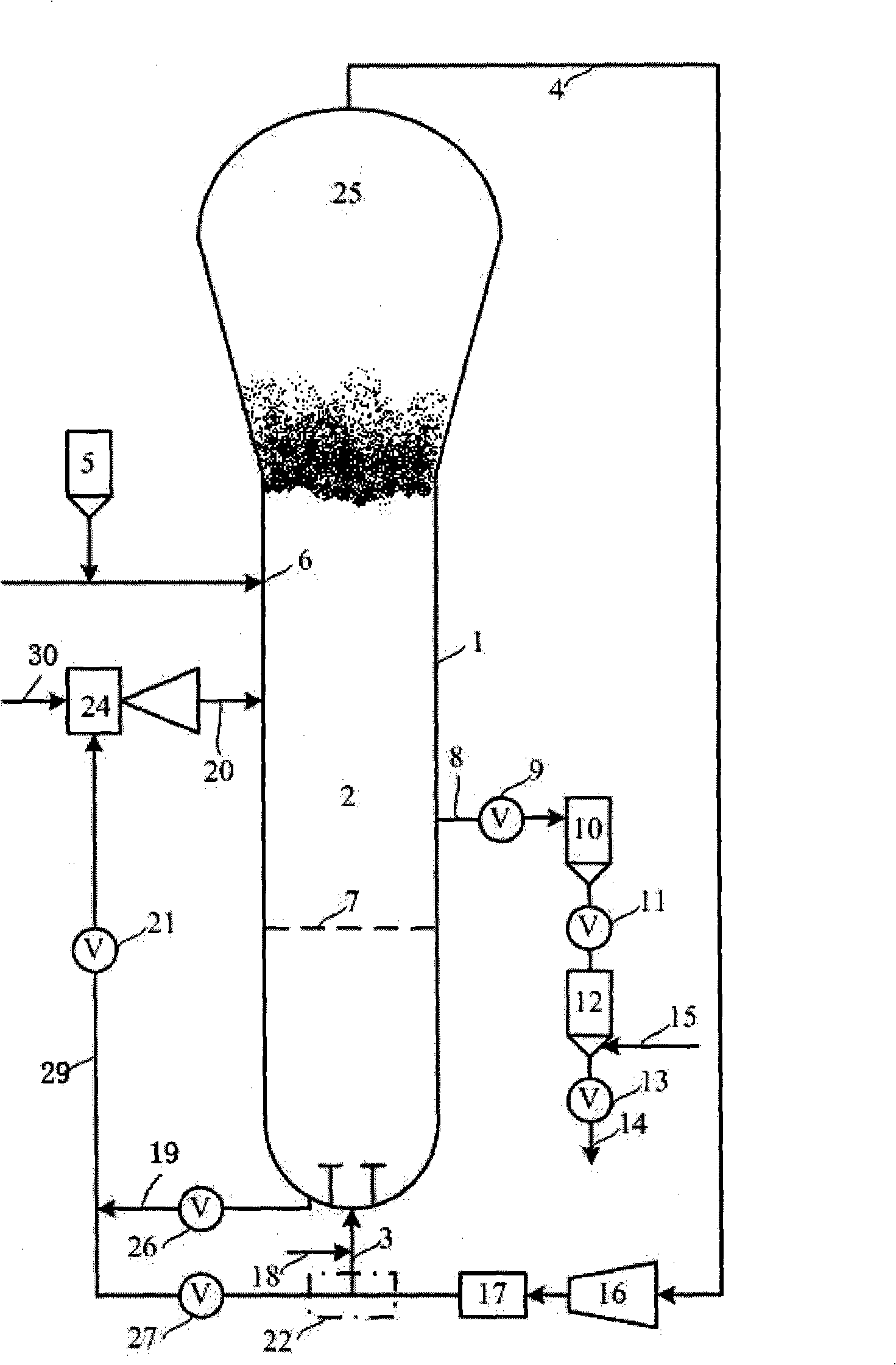

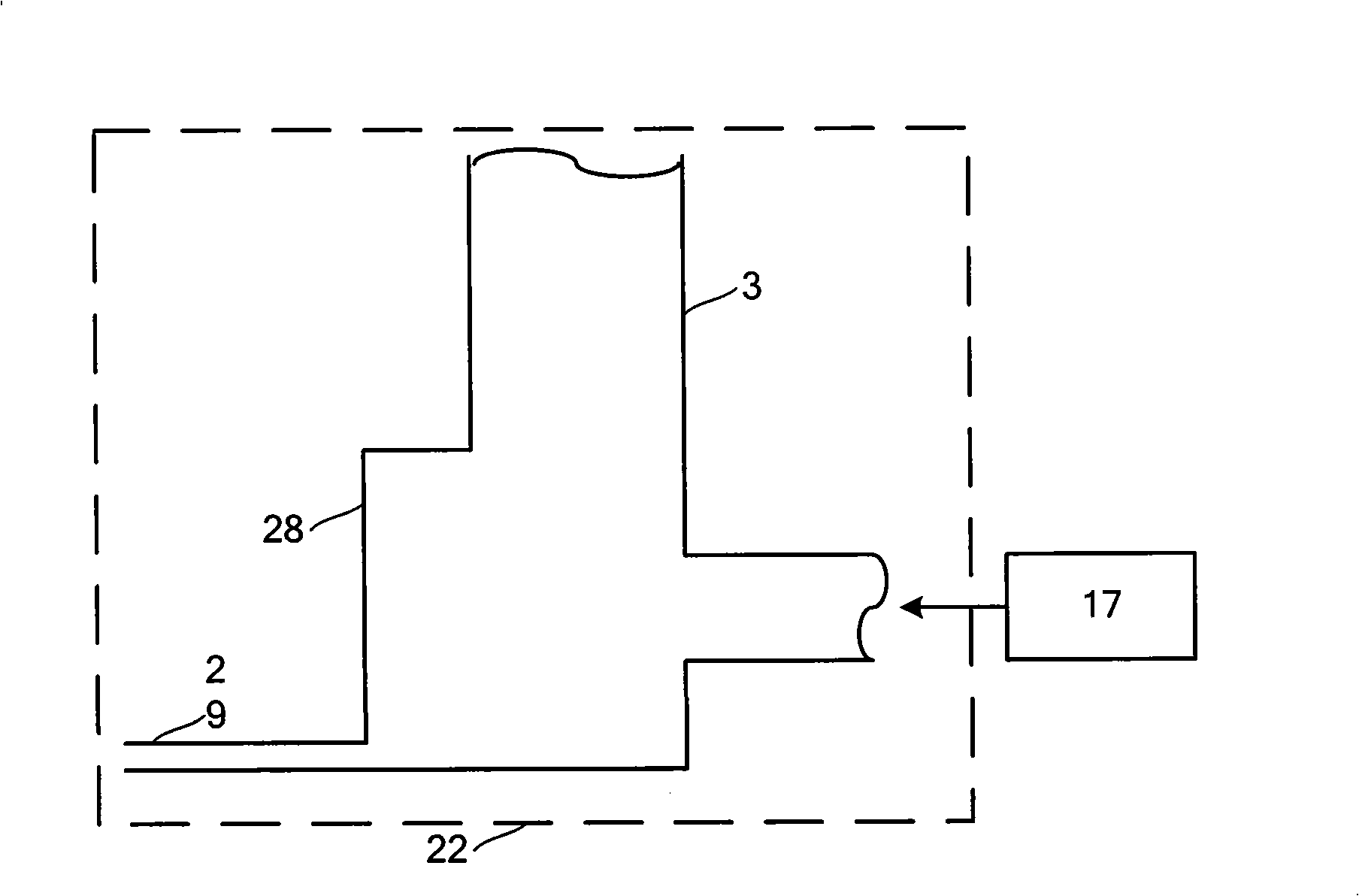

[0036] exist figure 1 Linear low density polyethylene (LLDPE) is produced in the fluidized bed polymerization reactor shown. Under the action of the Z-N catalyst system, the polymerization temperature is 85° C., the pressure is 2.1 MPa, and the superficial velocity of the reactor is 0.68 m / s. The circulating gas flow in the pipeline 4 includes hydrogen, nitrogen, methane, ethane, ethylene, hexene and hexane, etc., the pressure is 2.1MPa, and the temperature is 53°C. The circulating gas stream coming out of the condenser 17 contains 20% condensate, the liquid phase is hexene and hexane, and the density is 618.7kg / m 3 , the gas phase density is 28.8kg / m 3 . After separation and enrichment, the content of the condensate in the pipeline 29 can reach 30% of the total content of the condensate in the circulating gas stream, and the stream is sprayed into the fluidized bed from above the distribution plate through the jet pump 24 . In this process, the jet pump uses ethylene with ...

Embodiment 2

[0038] exist figure 1 Linear low density polyethylene (LLDPE) is produced in the fluidized bed polymerization reactor shown. Under the action of the Z-N catalyst system, the polymerization temperature is 80° C., the pressure is 2.1 MPa, and the superficial velocity of the reactor is 0.72 m / s. The circulating gas flow in the pipeline 4 includes hydrogen, nitrogen, methane, ethane, ethylene, and isopentane, the pressure is 2.1 MPa, and the temperature is 53°C. The circulating gas flow from the condenser 17 contains 30% condensate, the liquid phase is isopentane, and the density is 656.3kg / m 3 , the gas phase density is 28.8kg / m 3 . After separation and enrichment, the content of the condensate in the pipeline 29 can reach 50% of the total content of the condensate in the circulating air stream. . In this process, the jet pump uses ethylene with a flow rate of 20 tons / hour, a pressure of 2.7MPa, and a temperature of 25 °C as the power fluid, and the flow rate of the extracted...

Embodiment 3

[0040] exist figure 1 Linear low density polyethylene (LLDPE) is produced in the fluidized bed polymerization reactor shown. Under the action of the Z-N catalyst system, the polymerization temperature is 85° C., the pressure is 2.5 MPa, and the superficial velocity of the reactor is 0.78 m / s. The circulating gas stream in the pipeline 4 includes hydrogen, nitrogen, methane, ethane, ethylene, hexene and hexane, the pressure is 2.5MPa, and the temperature is 53°C. The circulating gas stream coming out of the condenser 17 contains 40% condensate, the liquid phase is hexene and hexane, and the density is 618.7kg / m 3 , the gas phase density is 28.8kg / m 3 . After gravity separation and enrichment, the content of the condensate in the pipeline 29 can reach 70% of the total content of the condensate in the circulating air flow. in the chemical bed. In this process, the jet pump uses ethylene with a flow rate of 35 tons / hour, a pressure of 3.2 MPa, and a temperature of 60 °C as the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com