Method for measuring wet natural gas flow rate by combining ultrasound with target flowmeter

A technology of ultrasonic flowmeter and target flow, which is applied in the direction of volume flow measurement device, liquid/fluid solid measurement, measurement device, etc. It can solve problems such as different mathematical models, health impact of staff, and complicated maintenance and use, so as to avoid Wear and restraint mechanism, easy maintenance and repair, easy installation and maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with accompanying drawing.

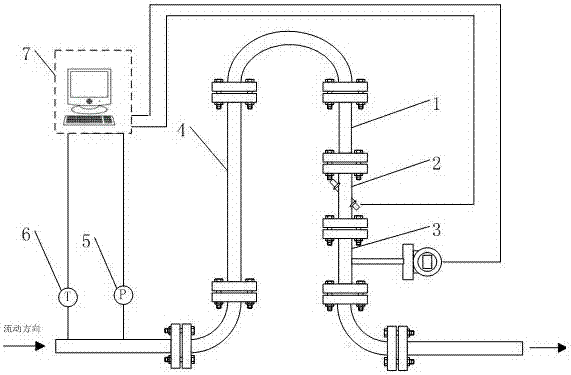

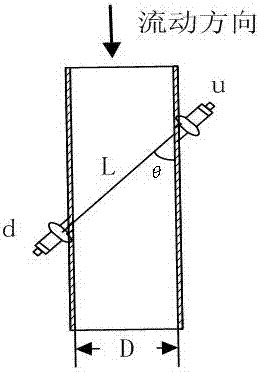

[0050] Such as figure 1As shown, the ultrasonic and target flowmeter combined wet natural gas flow measurement system of the present invention is processed by a nozzle rectifier 1, an ultrasonic flowmeter 2, a target flowmeter 3, a connecting pipeline 4, a pressure sensor 5, a temperature sensor 6 and a computer Unit 7 is composed. The measuring pipeline is an inverted U-shaped pipe, and the nozzle rectifier 1, the ultrasonic flowmeter 2 and the target flowmeter 3 are installed on the descending side of the inverted U-shaped pipe in sequence.

[0051] The working principle of the whole measurement system is as follows:

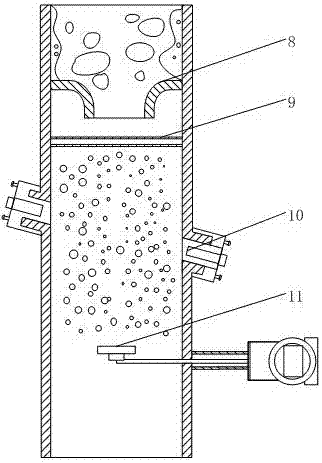

[0052] (1) Use nozzle rectifier 1 to obtain homogeneous flow

[0053] The common flow patterns of wet gas flow in horizontal pipelines are annular flow and stratified flow. In order to obtain homogeneous flow (or approximate homogeneous flow) to facilit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com