Method for improving heat transfer coefficient of heat exchanger by utilizing medium shear force

A heat transfer coefficient and heat exchanger technology, which is applied in heat transfer modification, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of high material requirements, difficult cleaning, complex structure, etc., to improve heat transfer coefficient, Improve heat transfer conditions and facilitate operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

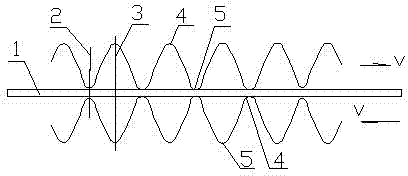

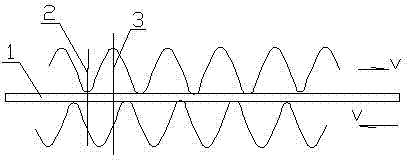

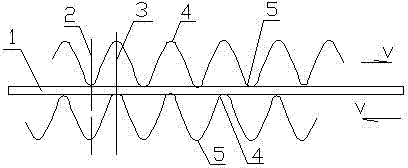

[0011] exist figure 1 , figure 2 , image 3 and Figure 4 In, a pulsation generator is set before the inlet of the heat exchanger (partition wall type), such as figure 1 As shown, the pulsation generator causes the fluid (medium) on both sides of the heat exchange surface 1 in the entire flow channel of the heat exchanger to generate a pulsation flow in which the direction of pulsation is opposite but the peak 4 and the trough 5 correspond to the same point on the heat exchange surface. The fluid medium on the upper side pulsates to the right, the fluid medium on the lower side of the heat exchange surface pulsates to the left, the trough 5 of the fluid pulsation on the upper side of the heat exchange surface and the peak 4 of the fluid pulsation on the lower side are on the vertical plane 2 of point A on the heat exchange surface Correspondingly, the peak 4 of the upper fluid pulsation on the heat exchange surface and the trough 5 of the lower fluid pulsation correspond t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com