Fine iron ore agglomeration additive and its preparation method

A technology for sintering additive and iron ore concentrate, applied in the field of additives, can solve the problems of reducing the iron grade of sintered ore, high production cost, complicated process, etc., and achieve the effects of reducing the amount of ore returning, reducing the returning rate and reducing environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

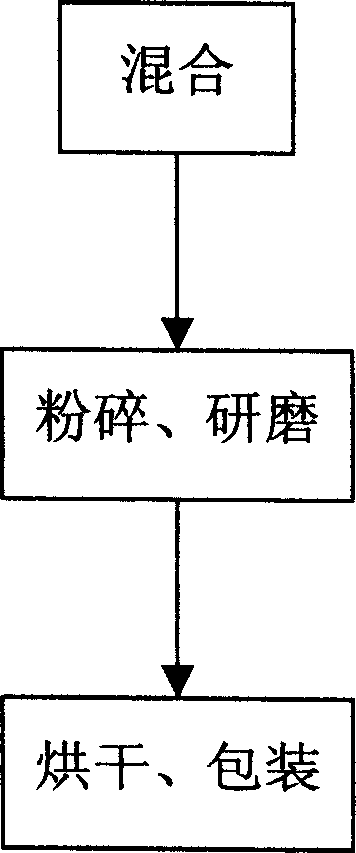

[0018] Below in conjunction with accompanying drawing of specification sheet, fine iron ore sintering additive of the present invention and preparation thereof are described further:

[0019] The fine iron ore sintering additive of the present invention is formed according to the following components and weight ratio:

[0021] Rare earth: 10~30%

[0022] Mica: 5~10%

[0024] Aluminum oxide: 5-10%

[0025] Diatomaceous earth: 6~10%

[0026] Ammonium nitrate: 10-20%

[0027] Boric acid: 20-40%

[0028] Iron oxide: 5-10%.

[0029] Introduce the preparation method of fine iron ore sintering additive below in conjunction with accompanying drawing:

[0030] 1. Mix quartz powder, rare earth, mica, magnesium oxide, aluminum oxide, diatomaceous earth, ammonium nitrate, boric acid, iron oxide and other raw materials on a common mixer;

[0031] 2. Pulverize and grind the mixed quartz powder, rare earth, mica, magnesiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com