Multi-stage heat exchanger

A heat exchanger and condenser technology, applied in the direction of evaporator/condenser, lighting and heating equipment, refrigeration components, etc., can solve the problem of reduced heat exchange efficiency of heat exchanger, unsatisfactory power consumption index, and failure to achieve cooling purposes and other problems, to achieve the effect of improving heat exchange efficiency, saving energy and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Structure of the present invention:

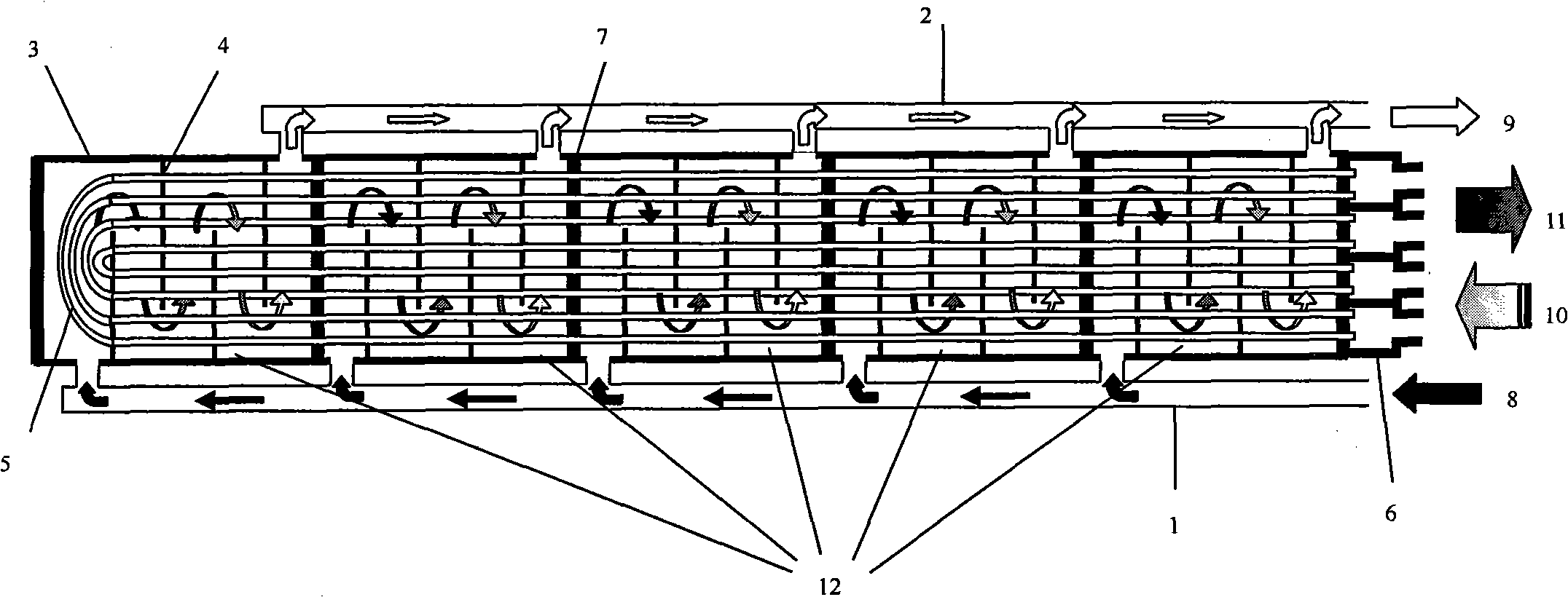

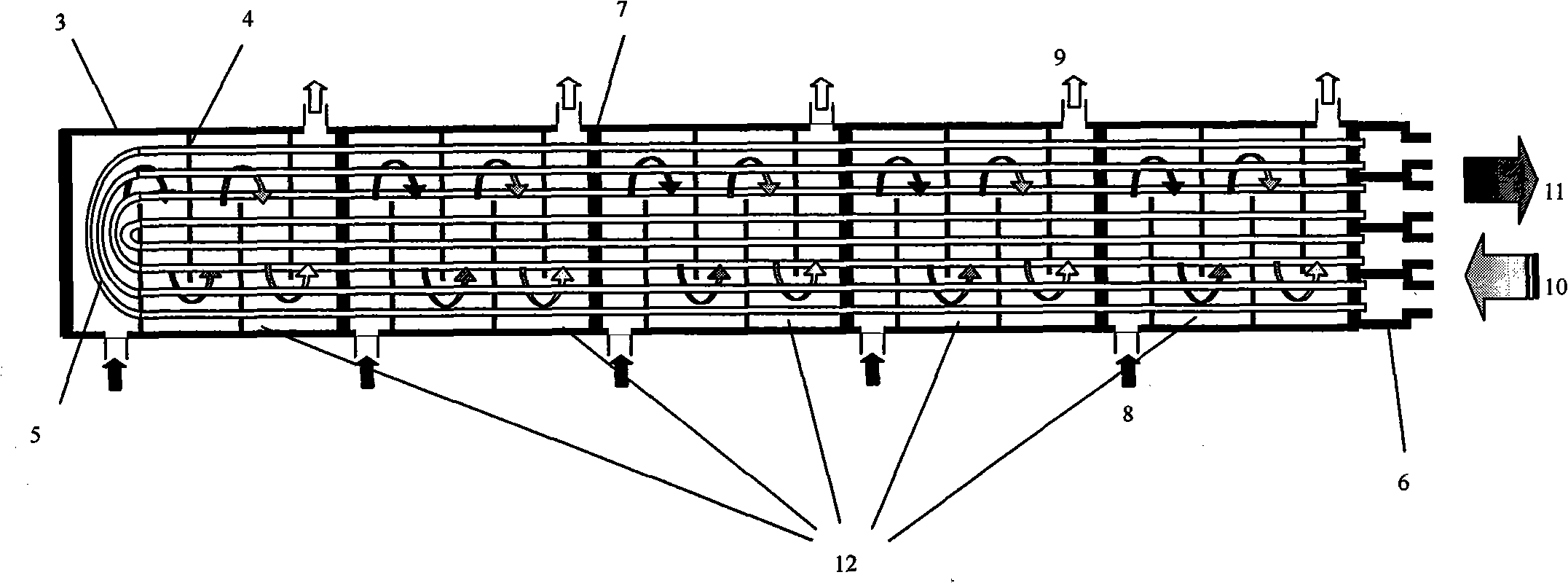

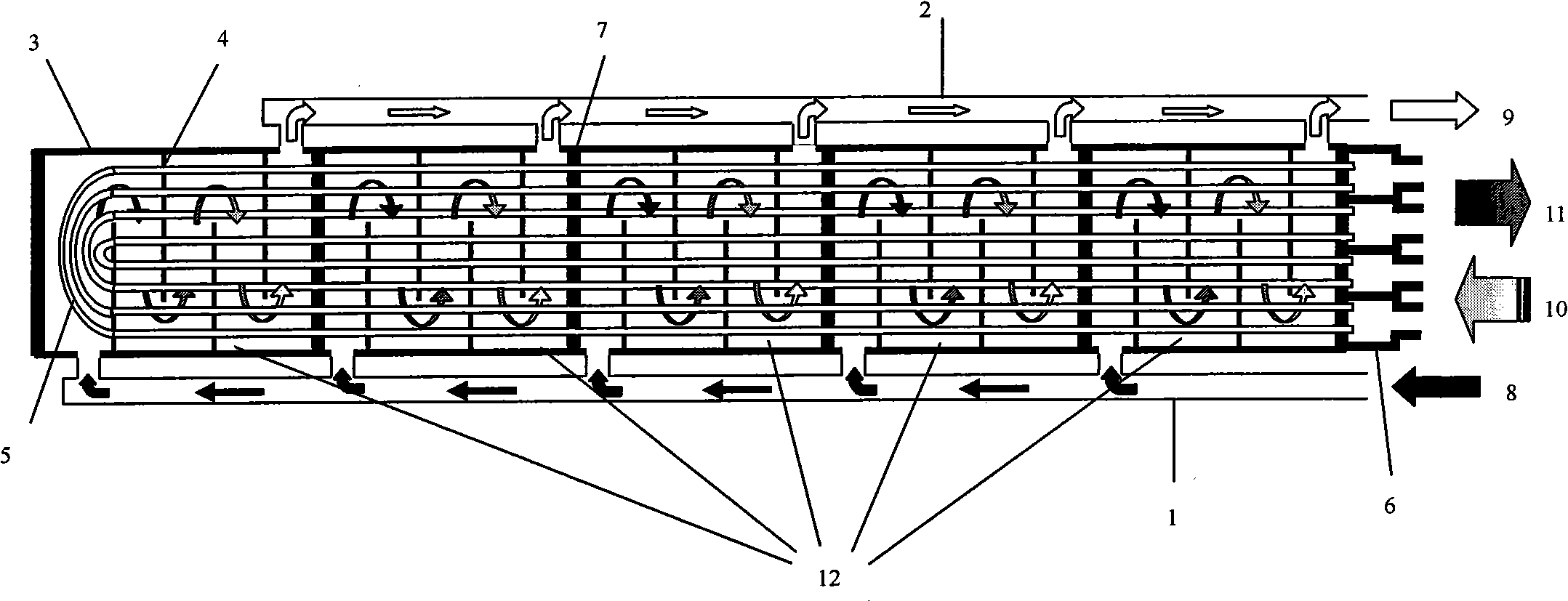

[0015] Such as figure 1 Shown:

[0016] The liquid inlet header 1 and the liquid outlet header 2 are arranged on both sides of the cylinder 3, or they can be arranged on the same side; the starting end of the liquid inlet header 1 is the liquid inlet 8, and the end of the liquid outlet header 2 is the liquid outlet 9. The partition plate 7 divides the cylinder body 3 into a plurality of cavities 12, in this example, five cavities 12; the head 6 divides the open end of the tube bundle 5 into multiple refrigerant inlets and outlets, in this example, 5 pairs The refrigerant inlet 10, the refrigerant outlet 11, together with the head 6 and the tube bundle 5 form 5 independent refrigerant inlet and outlet systems.

[0017] The liquid inlet 8 and the liquid outlet 9 of the liquid inlet header 1 and the liquid outlet header 2 can be in any orientation of the liquid inlet header 1 and the liquid outlet header 2 . Such as at both ends, at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com