External thermal coal base vertical furnace for producing direct reduction iron

A reduced iron and external heating technology, which is applied to furnaces, shaft furnaces, furnace types, etc., can solve the problems of high temperature resistance requirements for discharge equipment and water cooling equipment, large equipment investment, and short furnace life, so as to reduce subsidiary The effects of equipment investment, long furnace life and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

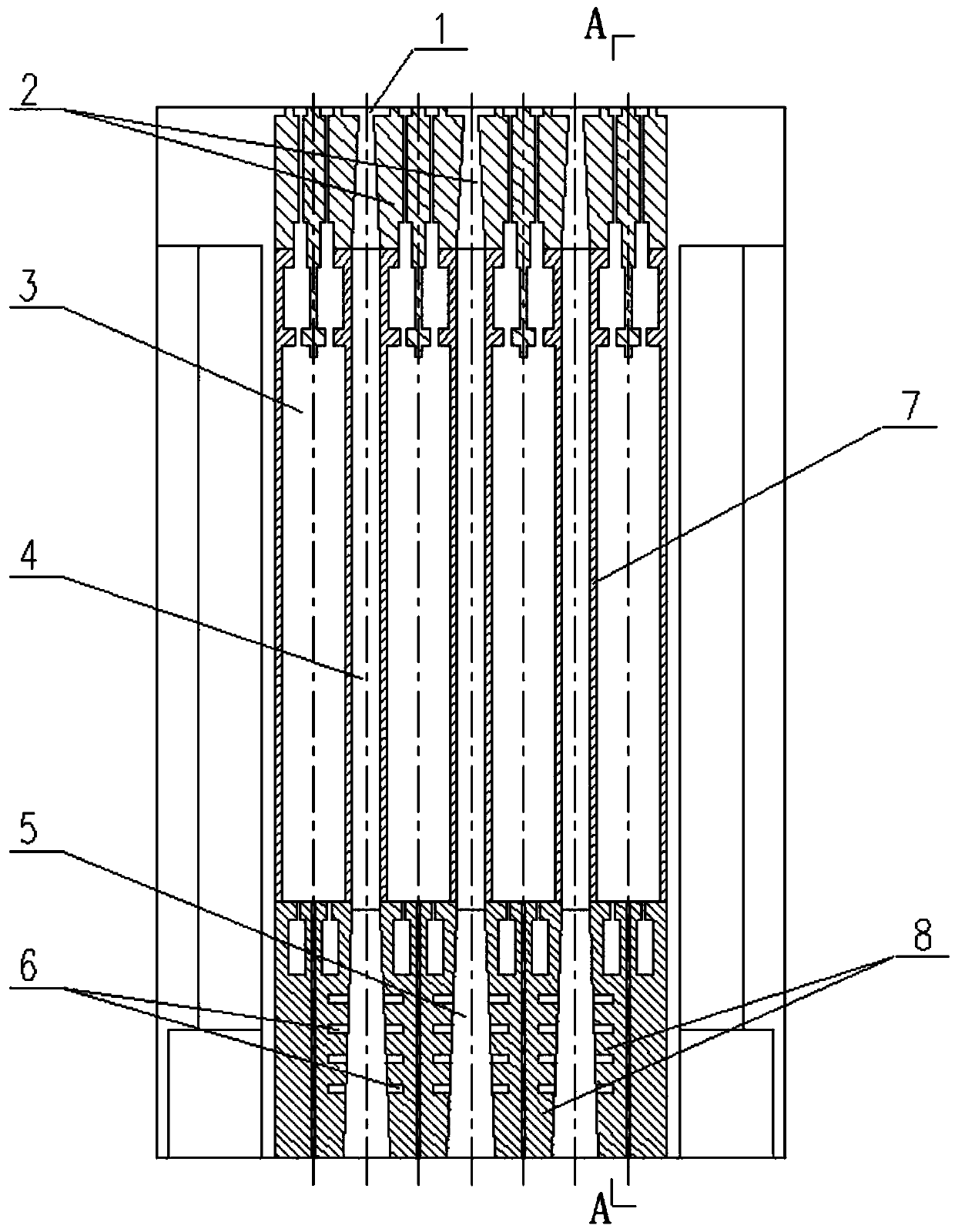

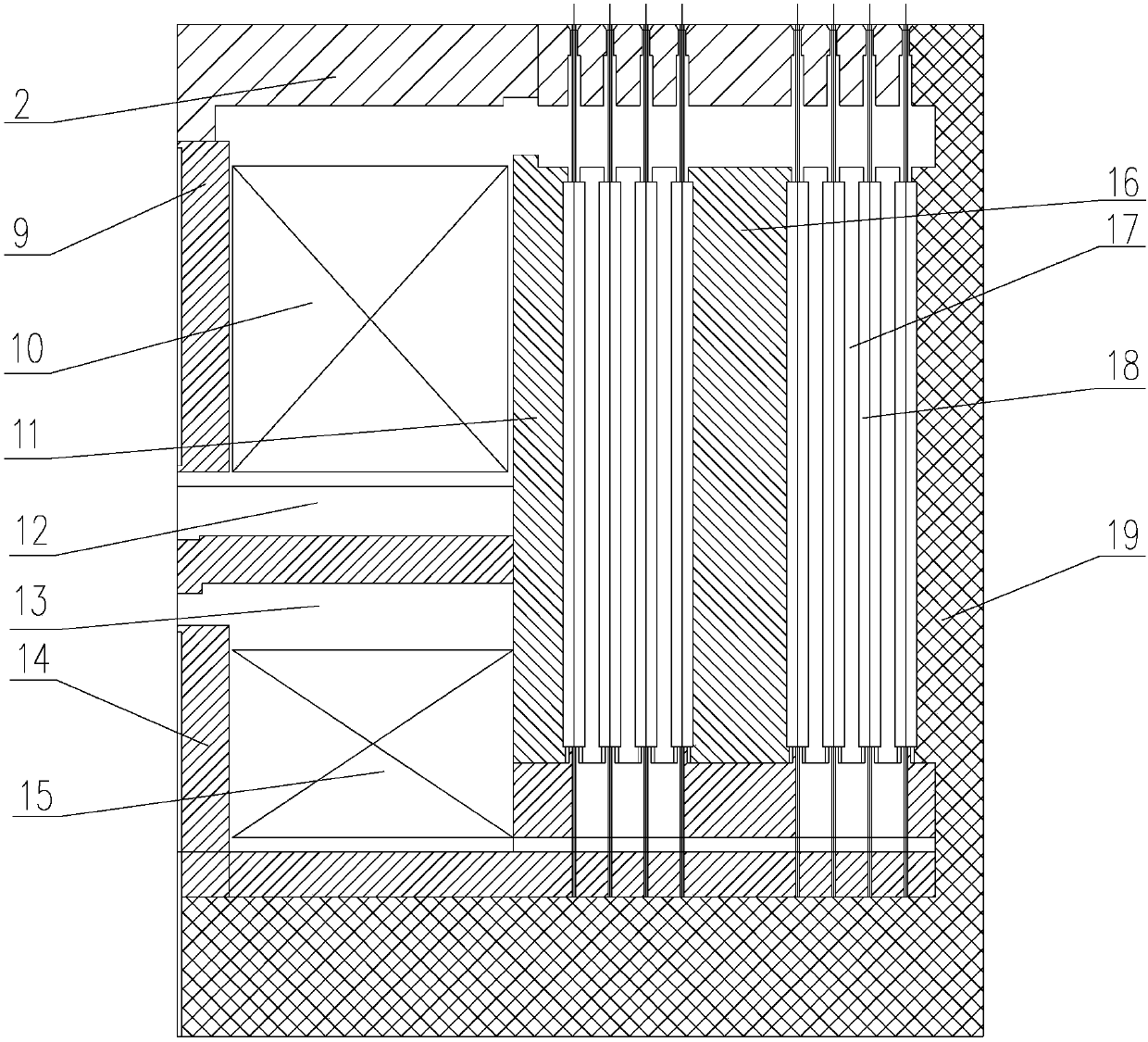

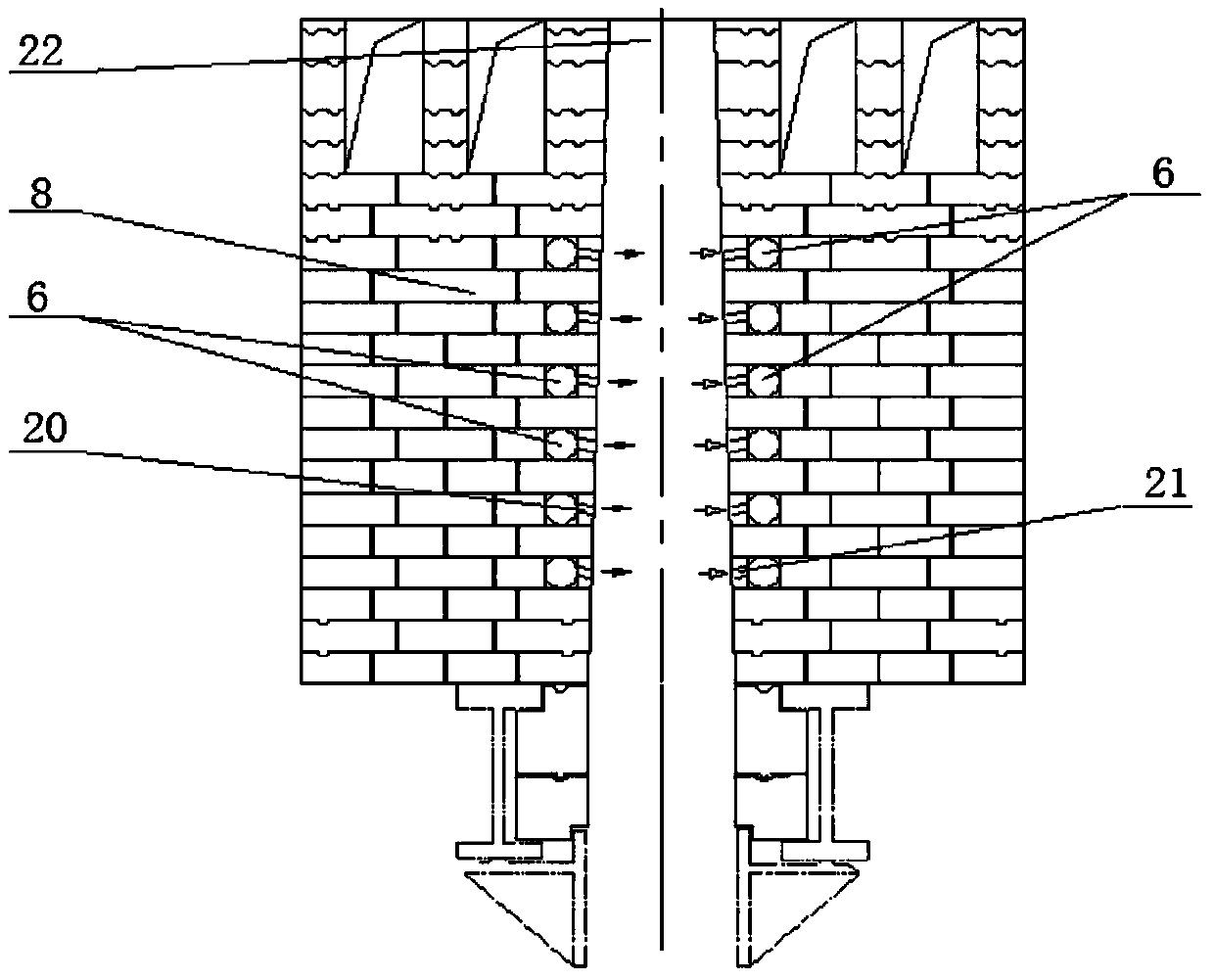

[0025] Such as figure 1 , figure 2 As shown, a kind of external heating type coal-based vertical furnace for producing direct reduced iron according to the present invention includes reduction chamber 4, combustion chamber 3, furnace top 2, regenerator and cooling chamber 5; combustion chamber 3 and reduction chamber Chamber 4 and cooling chamber 5 occupy one side of the furnace body, and the regenerator occupies the other side of the furnace body; the combustion chamber 3 and the reduction chamber 4 are distributed alternately, the cooling chamber 5 is located below the reduction chamber 4, and the top of the cooling chamber 5 is connected to the reduction chamber 4 connected; the furnace top 2 is located on the upper part of the combustion chamber 3; the regenerator includes an upper regenerator and a lower regenerator, one end of the upper re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com