Cooler descaling device

A cooler and high-pressure chamber technology, which is applied in the field of descaling devices for removing dirt on the inner wall of the cooler, to achieve the effects of saving descaling costs, high efficiency, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

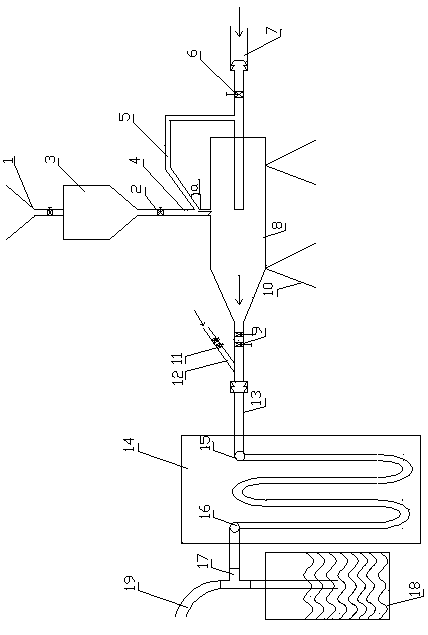

[0015] refer to figure 1 , a cooler descaling device of the present invention, the application on the cooler 14 of the blast furnace. The starting end of the device is a high-pressure gas source such as a high-pressure air pump (compressor) or other devices that generate high-pressure gas. A high-pressure chamber 8 is fixed on the bracket 10. The high-pressure gas source communicates with the high-pressure chamber 8 through a high-pressure valve 6 and a high-pressure intake pipe 7. , a pellet silo 3 is arranged on the upper part of the high-pressure chamber, and the pellet silo is communicated with the high-pressure chamber through a vertical discharge pipe 4, and a discharge valve 2 is arranged on the discharge pipe. There is also a receiving hopper 1 at the top of the pellet silo 3 . A high-pressure branch pipe 5 is connected to the high-pressure air inlet pipe 7, and the other port of the high-pressure branch pipe is connected with the blanking pipe 4 in a down-tilt state...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com