Segmented cooling system of belt type roasting machine

A technology of belt roaster and segmental cooling, which is applied to the types of furnaces, furnaces, lighting and heating equipment, etc. It can solve the problems of wasting the use area of belt roasters, the useless work of cooling fans, and the reduction of equipment utilization. Improve the cooling effect, optimize the gas circulation process, and improve the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with drawings and embodiments.

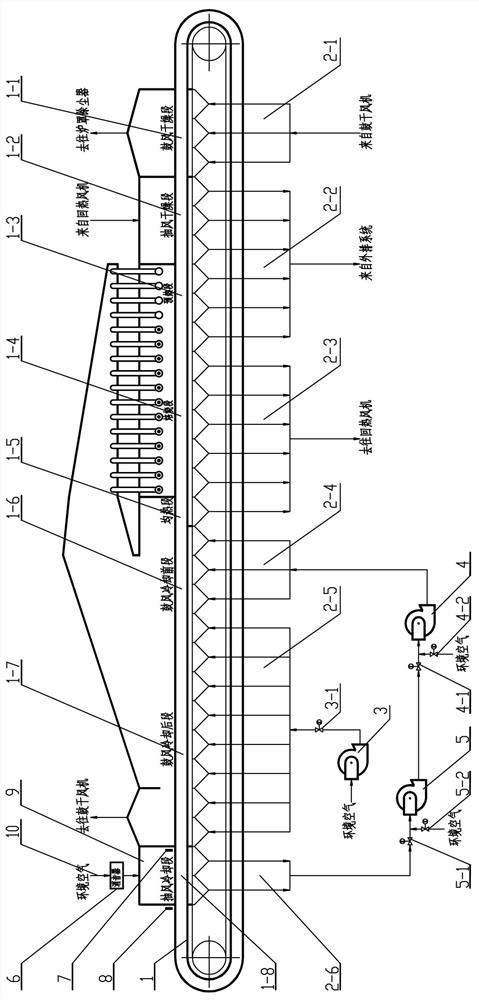

[0031] like figure 1 As shown, a kind of band roaster sectional cooling system of the present invention comprises band roaster 1, and band roaster is respectively divided into air blast drying section 1-1, suction drying section 1-2, Preheating section 1-3, roasting section 1-4, soaking section 1-5 and blast cooling section, the bellows are divided into four groups, the first group of bellows 2-1 corresponds to the blast drying section, the second group of bellows 2- 2 Corresponds to the draft drying section 1-2, the preheating section 1-3 and the front part of the roasting section 1-4, the third group of bellows 2-3 corresponds to the rear part of the roasting section 1-4 and the soaking section, and the fourth group of bellows corresponds to the drum The air cooling section is characterized in that it also includes: No. 1 cooling blower 4, No. 2 cooling blower 3, coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com