Lower jet type spraying thrust aerating and cooling tower, and jet flow cool wind machine

A technology of ventilation cooling and cooling fan, applied in water shower cooler, space heating and ventilation, heating method, etc., can solve the problems of floating water at the top of the tower, complex structure, loud noise, etc., to save electric power and distribute water evenly , the effect of resolving noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

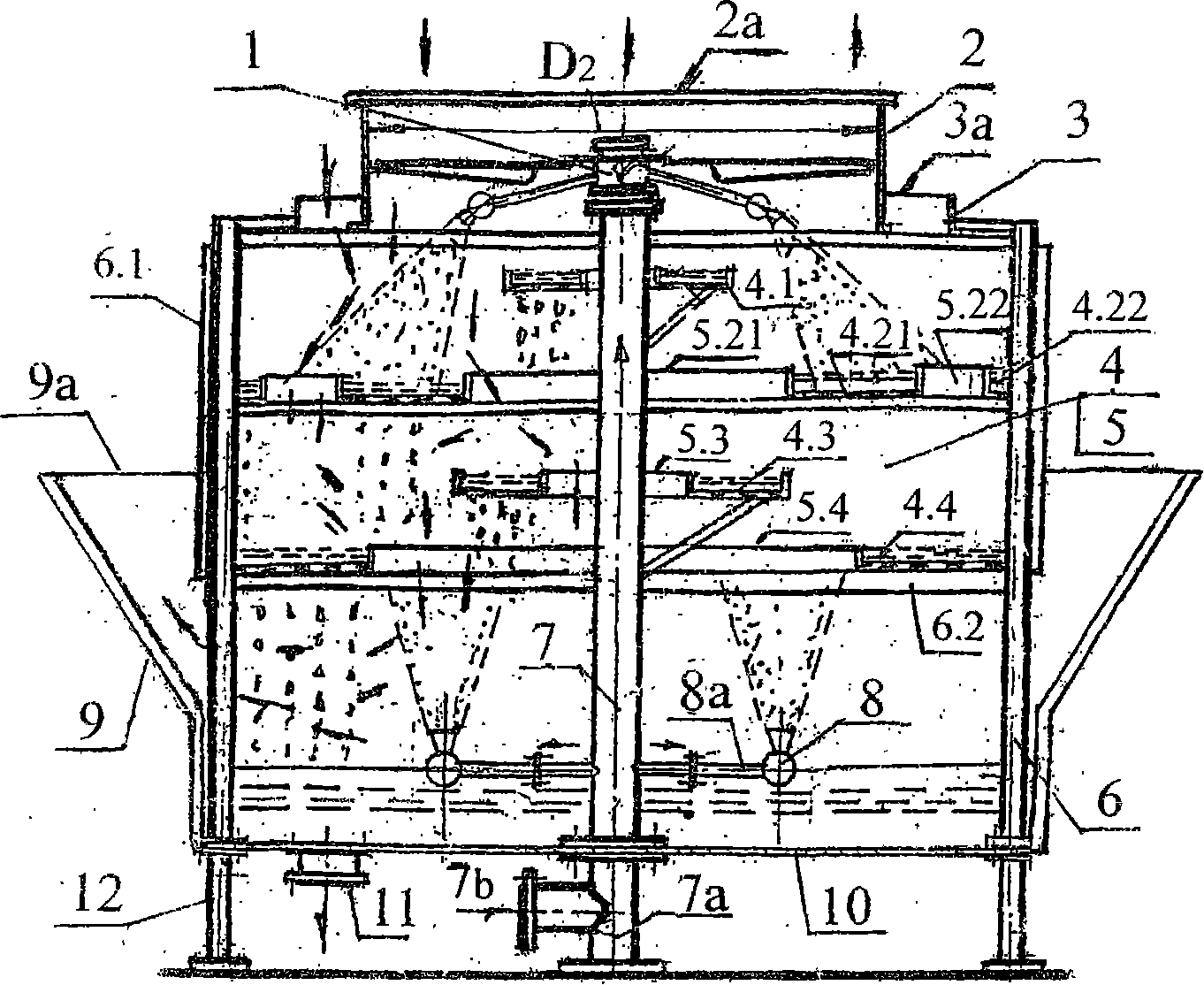

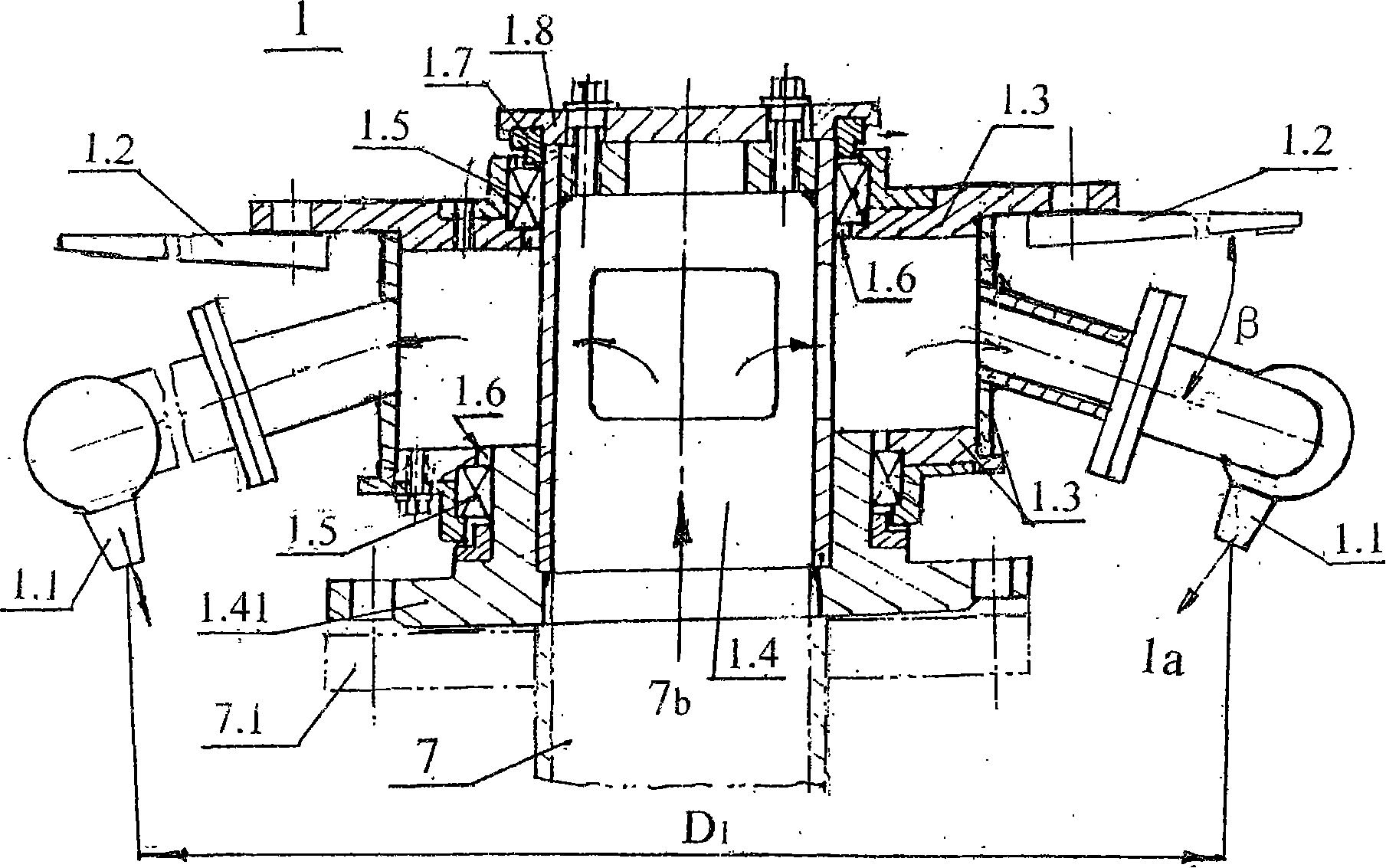

[0017] Example 1: see figure 1 , image 3 , Figure 4

[0018] See figure 1 , The downspray spray propulsion ventilation cooling tower is composed as follows: the top of the tower body 6 is provided with a primary air inlet tube 2, which forms a primary air inlet 2a; The side wall of the middle and lower part of the tower body is fully opened with an air outlet, where an air bucket 9 with a water accumulation function is installed to form an air outlet 9a. When the tower body is a tetrahedron, the wind bucket is a four-sided inverted trapezoid; when the tower body is a cylinder, the wind bucket is an inverted cone. The area of the air outlet 9a is greater than the sum of the areas of the air inlets 2a and 3a. The tower body 6 is welded together by a plurality of supporting steel pipes or water pipes, the tower wall is formed by sealing the tower plate 6.1, and a support member 12 is arranged under the tower body. The spray device 1 is installed in the primary air inl...

Embodiment 2

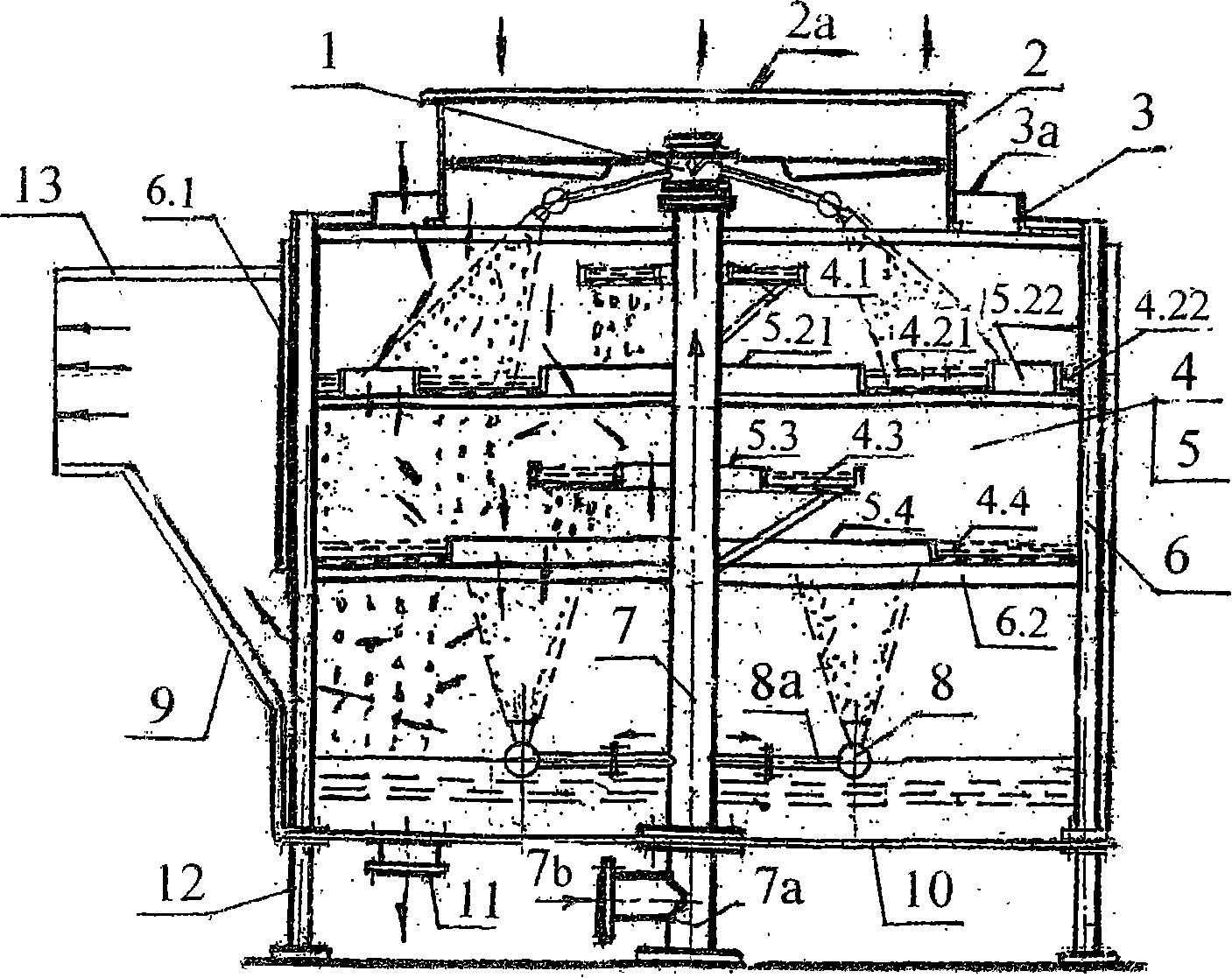

[0025] Example 2: Jet Cooler

[0026] See figure 2 , except that the structure of the downspray spray propelling ventilation cooling tower of embodiment 1 is all the same except for the following, the difference: 1. if the tower body 9 is a square, the area of the air outlet is 1 / of the area of the fully opened air outlet on the side wall of the tower body 4. That is, the three sides of the tower wall are sealed, and only one side is equipped with a wind bucket 9 . 2. install the air delivery pipe 13 on the air funnel. ③The water inlet pipe 7 is refrigerant water (7~20° C.), the air intake is hot and humid wind, and the air outlet is cold and wet wind. The raised hot water is in the sump tank and the water outlet pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com