Patents

Literature

31results about How to "Increase temperature drop" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

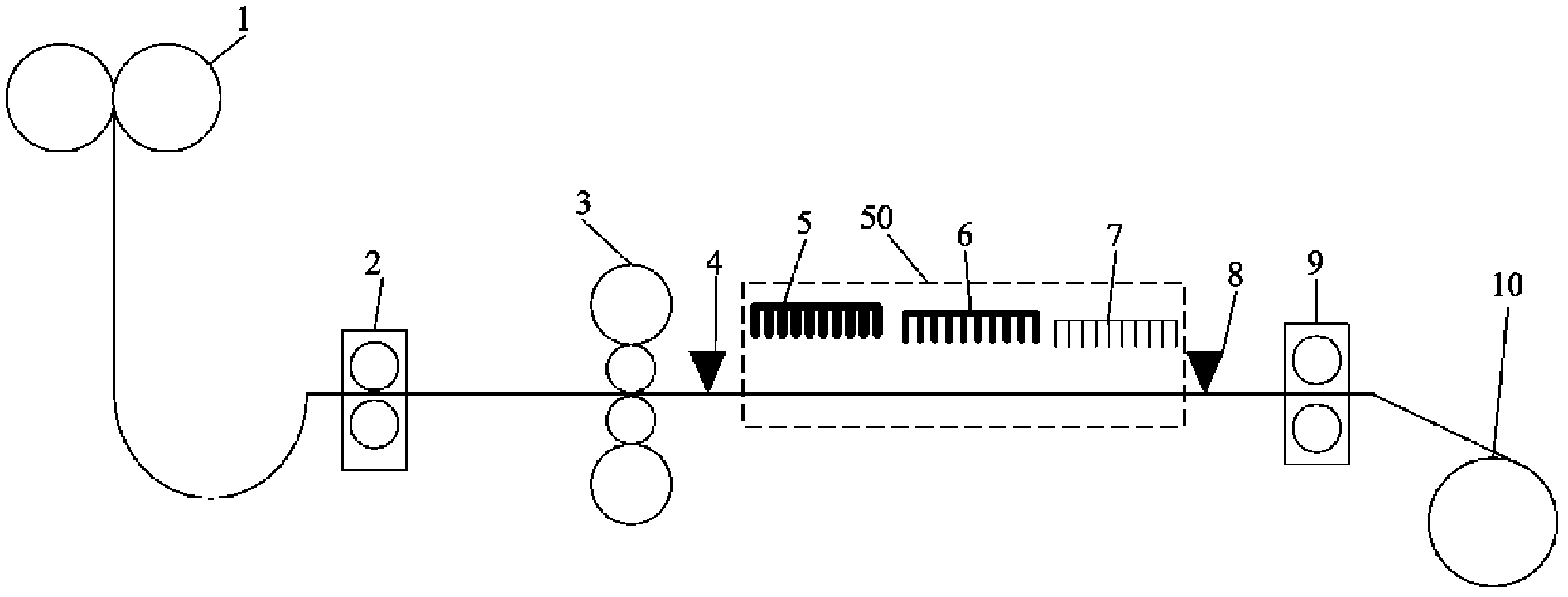

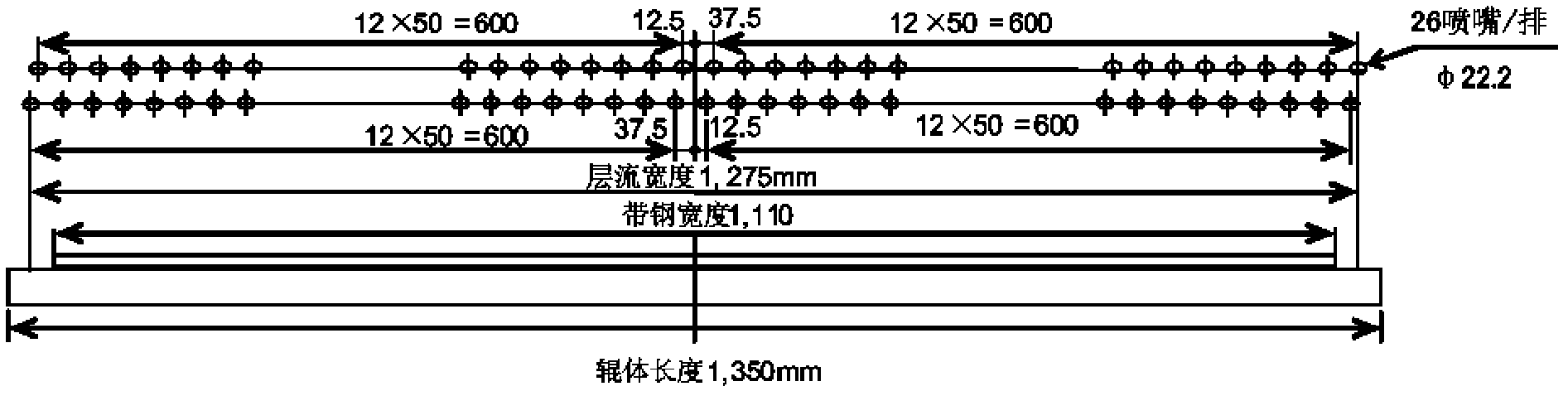

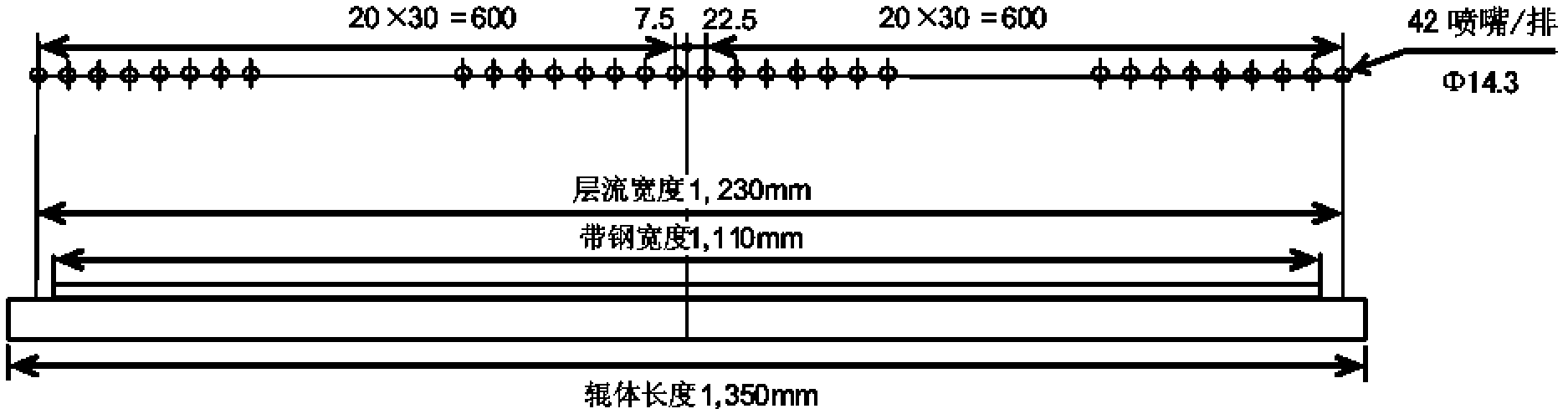

Cooling system for rolled stripe continuously-casting production line and control method thereof

ActiveCN102553950AMeet the temperature dropFulfil requirementsTemperature control deviceWork treatment devicesAdaptive learningLow speed

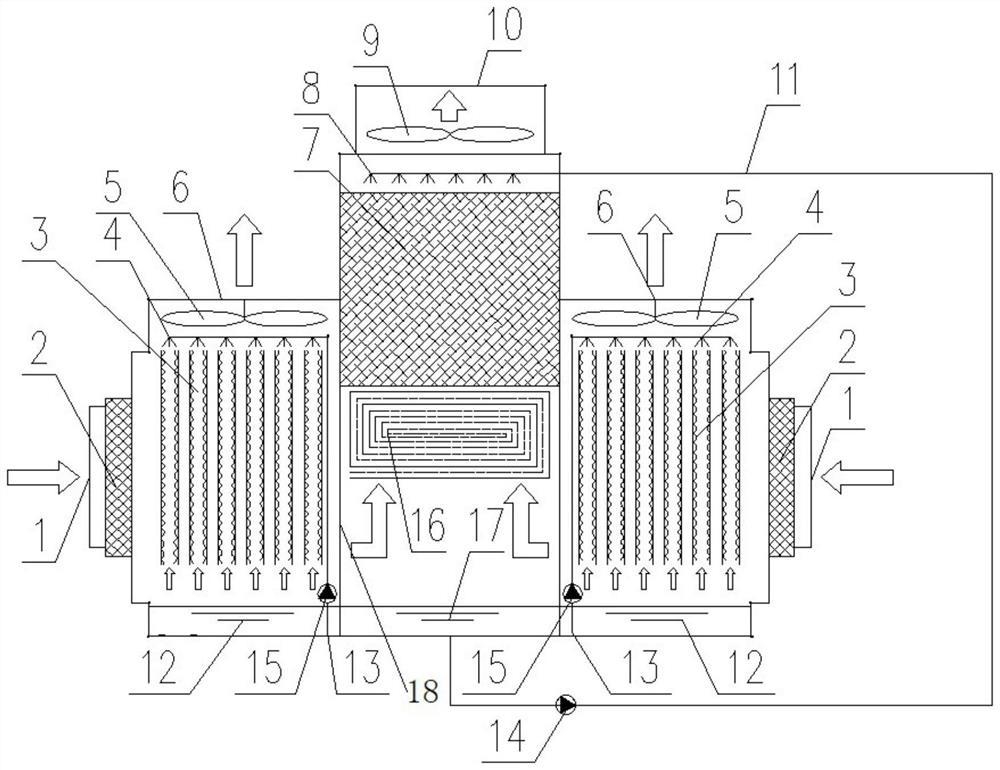

The invention relates to control devices or methods specially for metal rolling machines and manufacturing products of the metal rolling machines and discloses a cooling system for a rolled stripe continuously-casting production line and a control method of the cooling system. The system comprises a segmented laminar flow cooling device and a cooling control system which are arranged behind an online hot rolling machine, wherein the segmented laminar flow cooling device comprises at least two segmented laminar flow cooling collecting pipe areas, wherein one of the at least two segmented laminar flow cooling pipe collecting areas adopts a nozzle cooling collecting pipe with small pipe diameter, the cooling control system is an online double-closed-loop control system and comprises a double-closed-loop control circuit, the double-closed-loop control circuit comprises a feedforward control module, a precomputation module, a feedback control module, a coiling-ahead temperature measuring module and a self-adaption learning module, the double-closed-loop control circuit selects at least one collecting pipe area of the segmented laminar flow cooling device, the number of open collecting pipes in the selected collecting pipe area can be adjusted by a group of control valves, and the requirements on the accuracy of coiling temperature of steel stripes rolled at a low speed during the variation of speed and thickness in a limited cooling area can be met by the nozzle cooling collecting pipe with the small pipe diameter and the online double-closed-loop control system.

Owner:BAOSHAN IRON & STEEL CO LTD

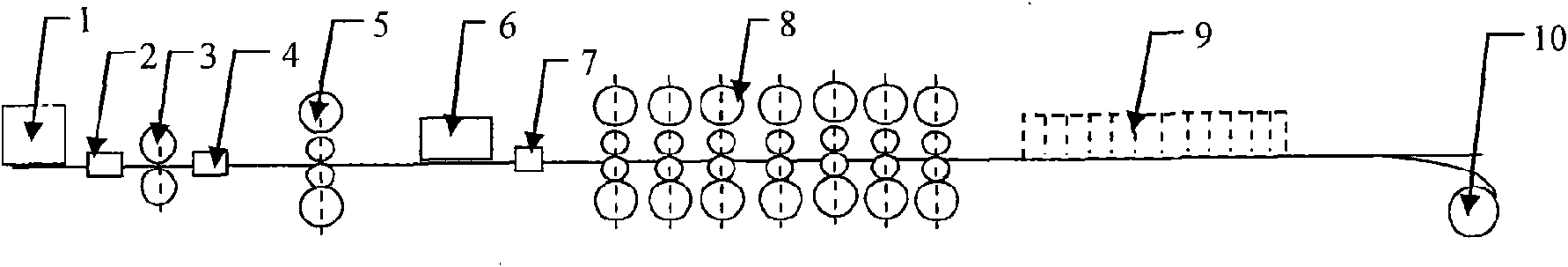

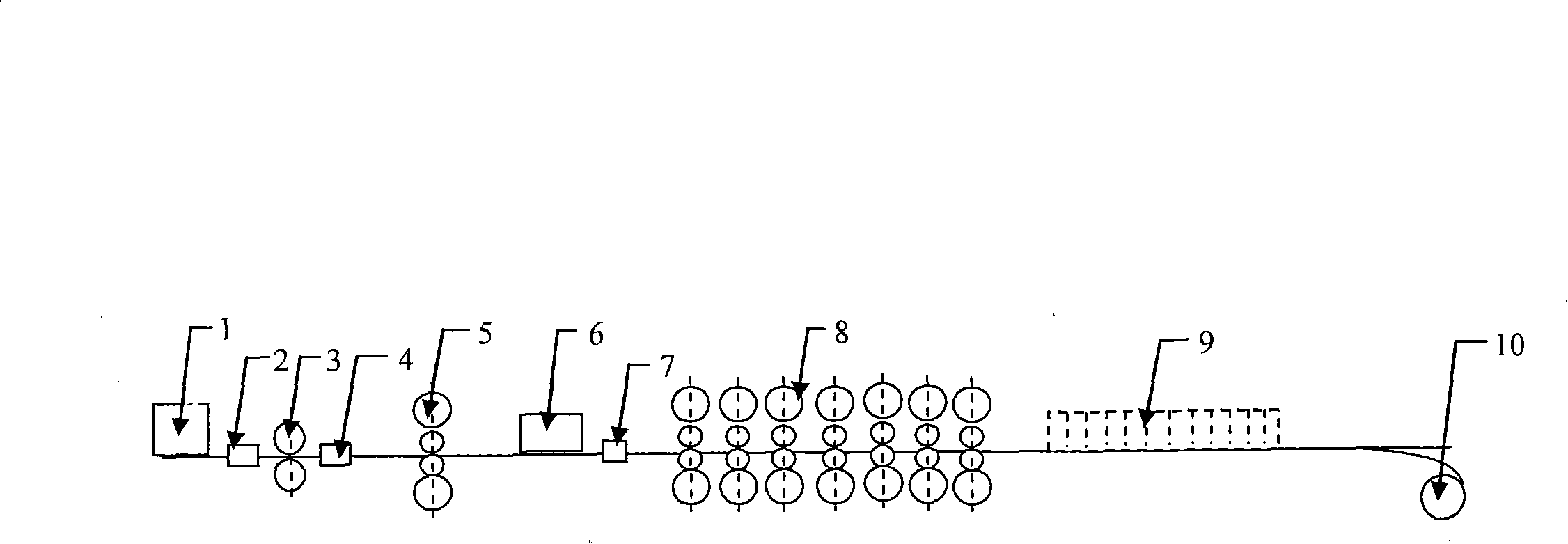

Method for rolling interstitial free steel ferrite on traditional hot rolling mills

ActiveCN101618396AImprove deep drawing performanceImprove organizational structureTemperature control deviceWork treatment devicesLaminar coolingHeating furnace

The invention relates to an IF steel rolling method, in particular to a method for rolling interstitial free steel ferrite on traditional hot rolling mills, which mainly solves the technical problem that finish rolling of the traditional IF steel austenite-region rolling is easy to fall into a two-phase region. The method for rolling interstitial free steel ferrite on traditional hot rolling mills comprises the steps of heating a slab through a heating furnace, performing rough rolling in a rough rolling mill, performing finish rolling in a finish rolling mill, performing laminar cooling and coiling. The method is characterized in that rough rolling is performed in an austenite region; the slab is cooled to the temperature at which an austenite structure is basically changed into a ferrite structure after rough rolling is over; finish rolling is performed in a ferrite region; the heating temperature of the slab is 1,130 + / - 20 DEG C; the inlet temperature of finish rolling is 850 + / - 20 DEG C; the final rolling temperature is 820 + / - 20 DEG C; the coiling temperature is 710 + / - 20 DEG C; and the thickness of an intermediate slab is 36 to 40 mm. The method mainly performs IF steel rolling on the traditional hot rolling mills.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

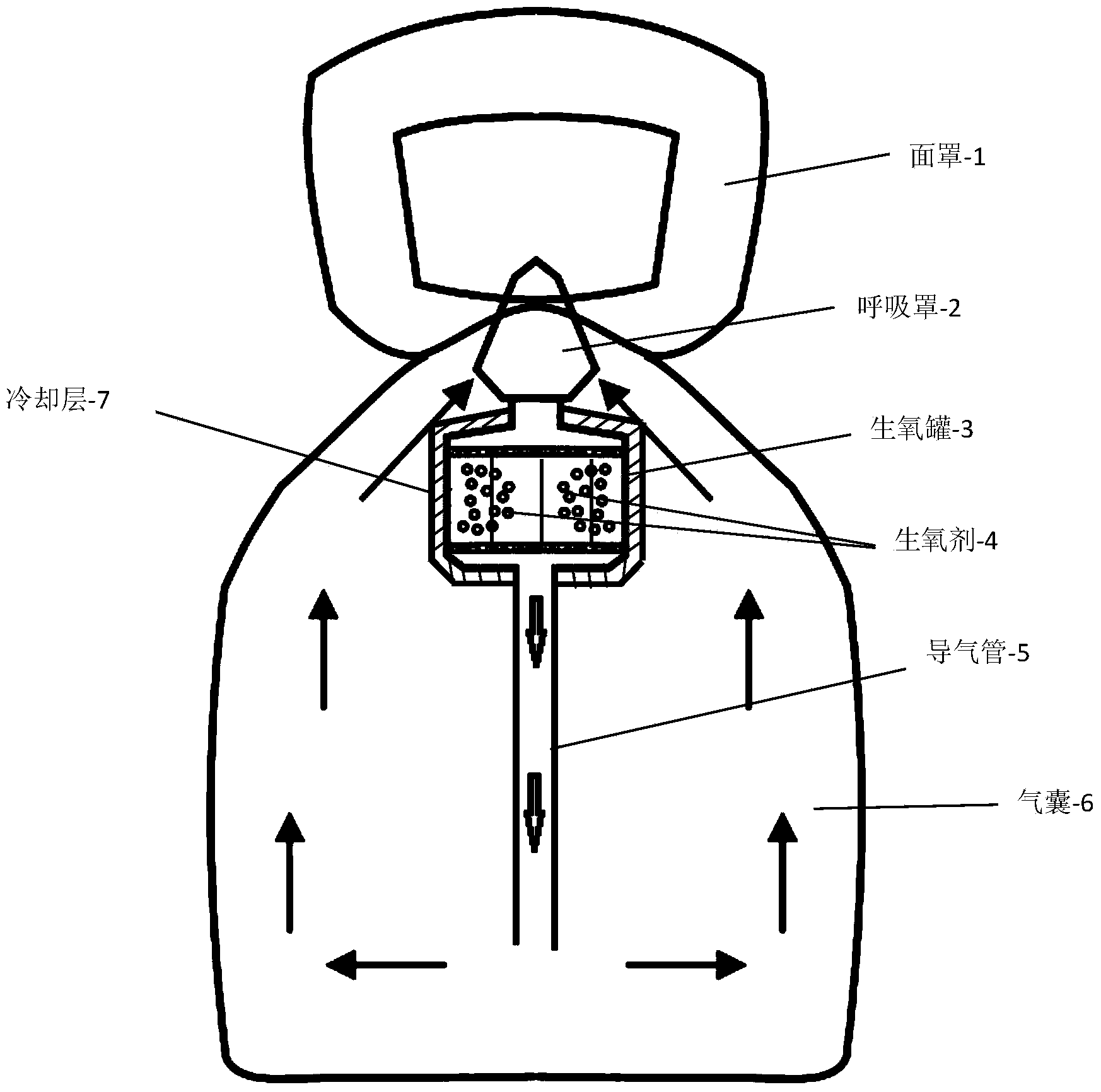

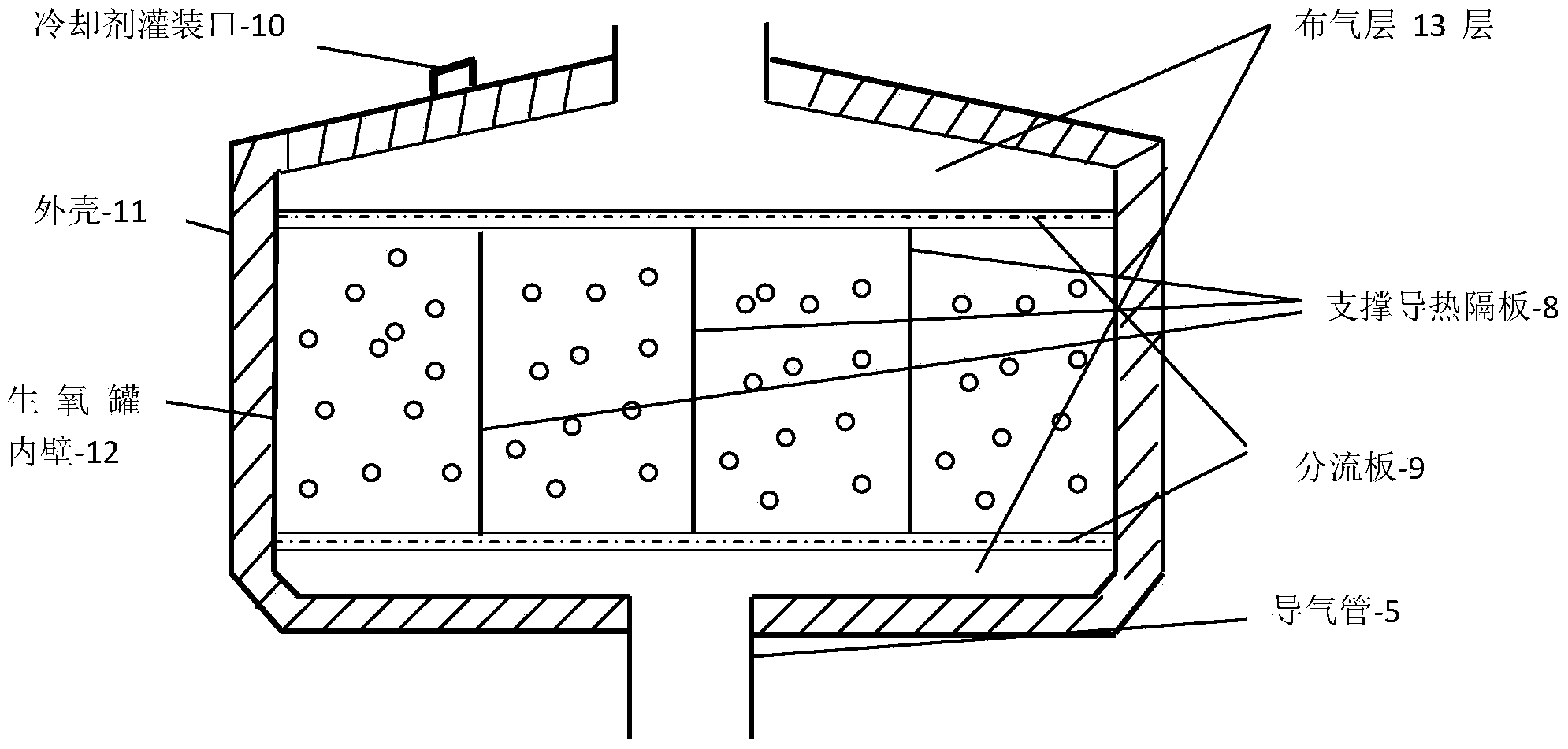

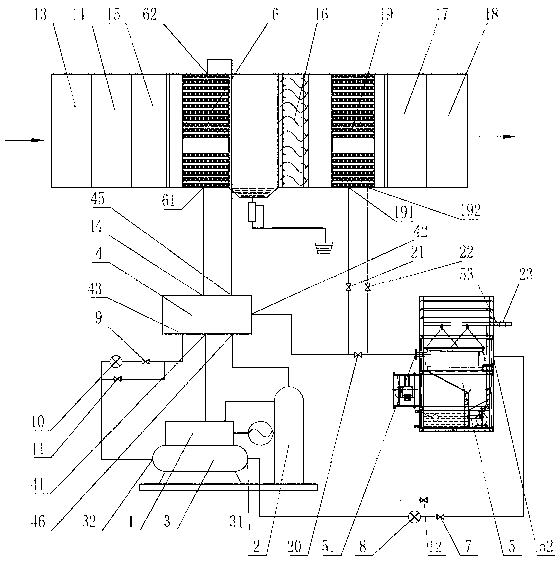

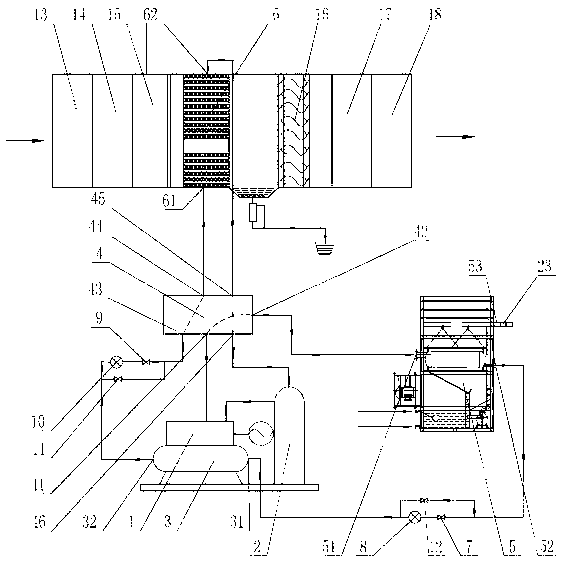

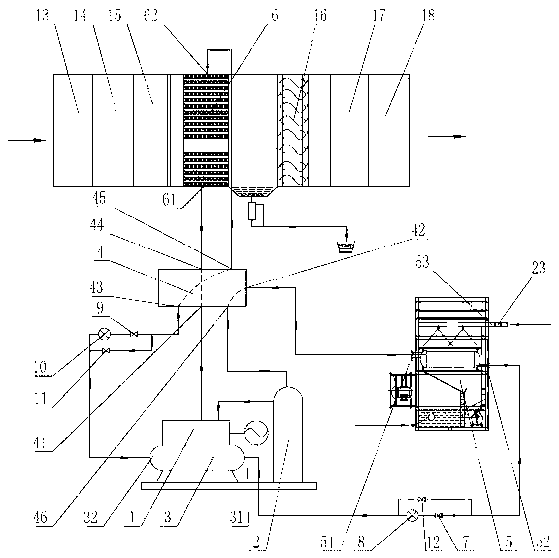

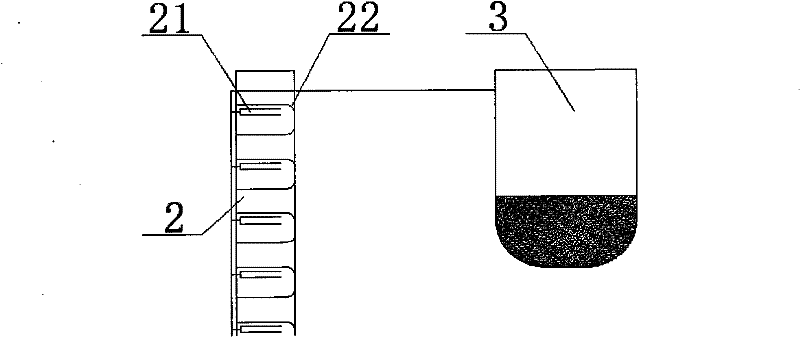

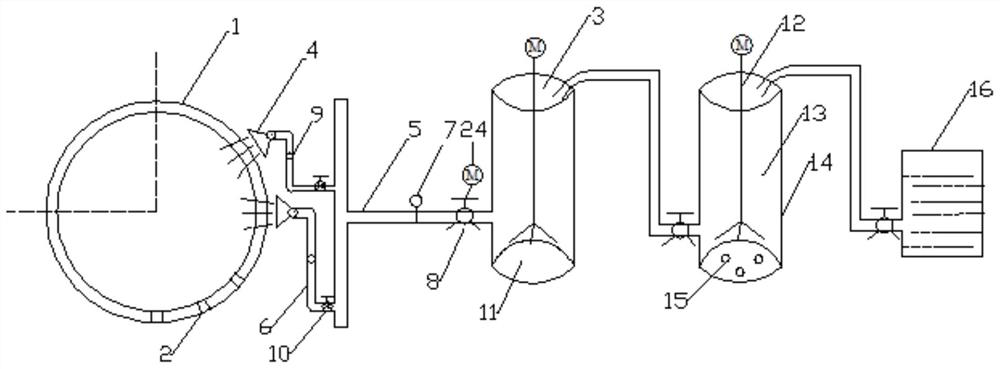

Efficient oxygen-generation and air stagnation prevention chemical oxygen fire-fighting self-rescue respirator with cooling layer

InactiveCN103706053ASolve for uniformitySolve the cooling problemFire rescueRespiratory apparatusRespiratorIsolation layer

The invention provides an efficient oxygen-generation and air stagnation prevention chemical oxygen fire-fighting self-rescue respirator with a cooling layer. The chemical oxygen fire-fighting self-rescue respirator comprises a mask (1), a breathing cover (2), an oxygen-generation tank (3) and an airbag (6), and is characterized in that the breathing cover is arranged on the mask and is connected with an opening of the airbag; an expiration one-way valve and an inspiration one-way valve are arranged at the connecting position of the breathing cover and the airbag; the oxygen-generation tank is arranged in the airbag, and an air inlet in the top of the oxygen-generation tank is connected with the breathing cover through the expiration one-way valve; meanwhile an air guide tube is connected with an air outlet in the bottom of the oxygen-generation tank. According to the self-rescue respirator, the oxygen-generation tank is arranged in the airbag, the airbag is effectively prevented from being wrinkled or adhered, and the air stagnation phenomenon is completely eradicated; a flow channel subdivision staggered fin type cooling structure is adopted in the oxygen-generation tank, the problem that the reaction in a medicament layer is uneven and the cooling problem are effectively solved, and meanwhile the temperature of generated oxygen is effectively lowered through the arrangement of a supporting heat conduction separation plate, a heat isolation layer and the air guide tube.

Owner:BEIJING ANYANGTE TECH

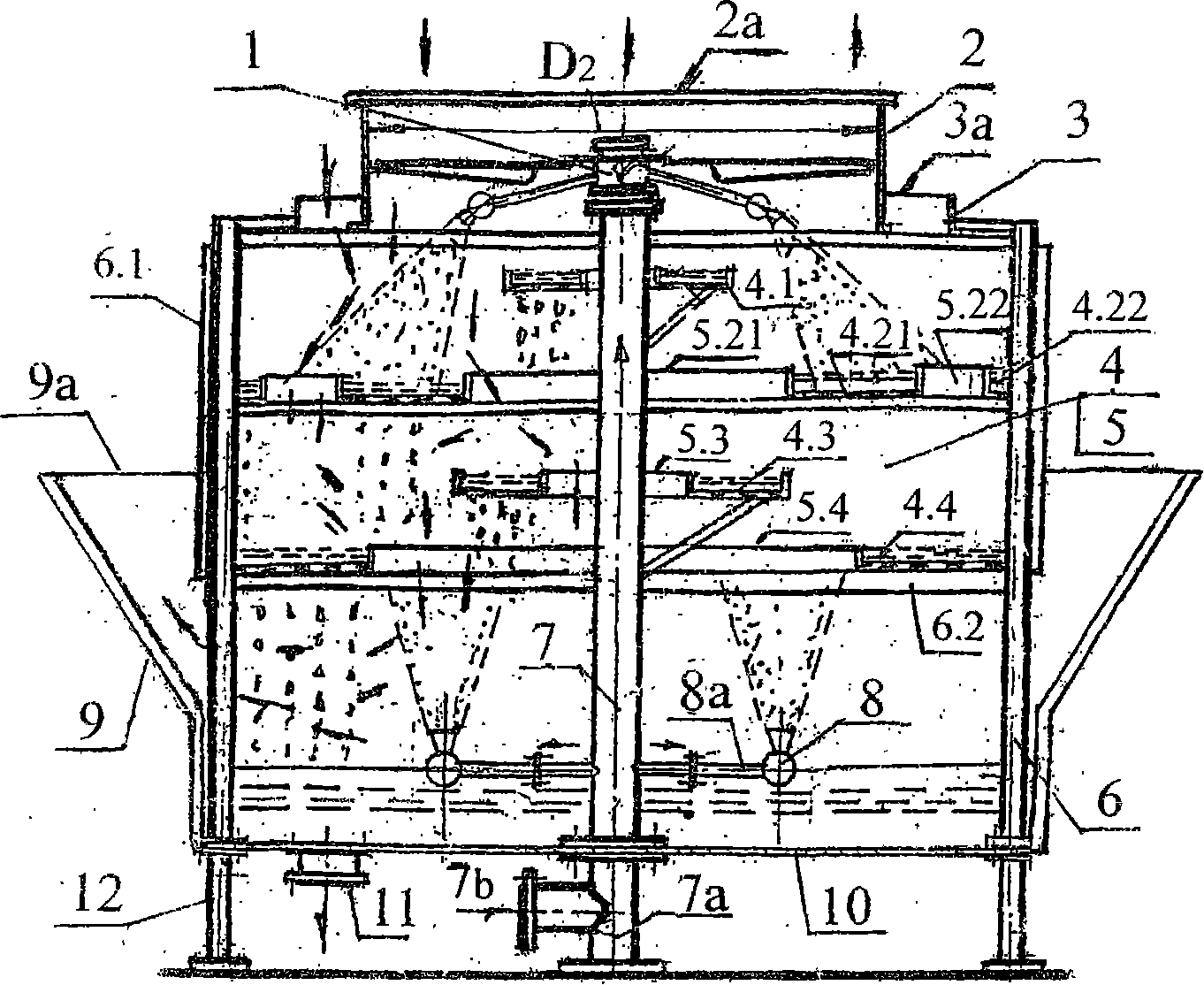

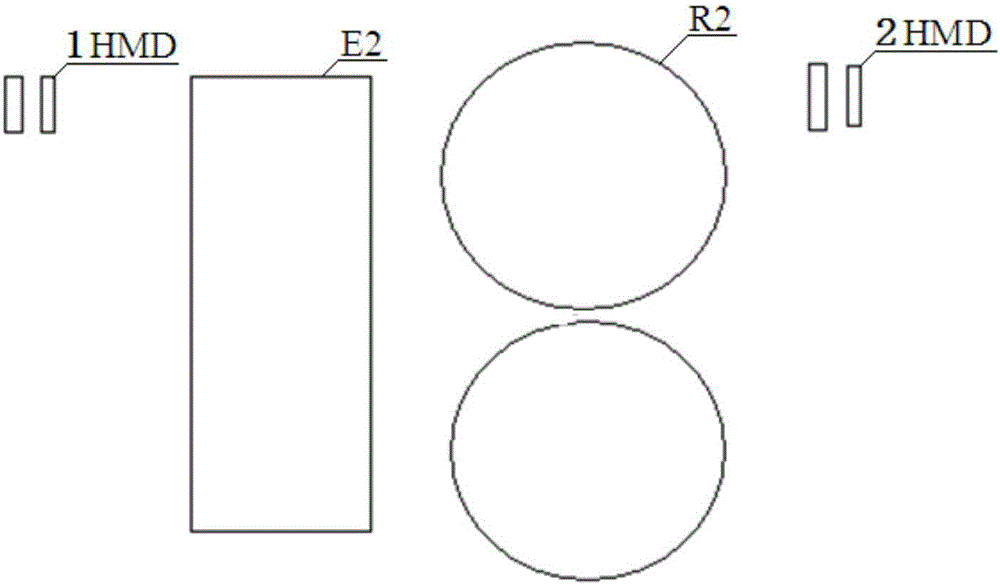

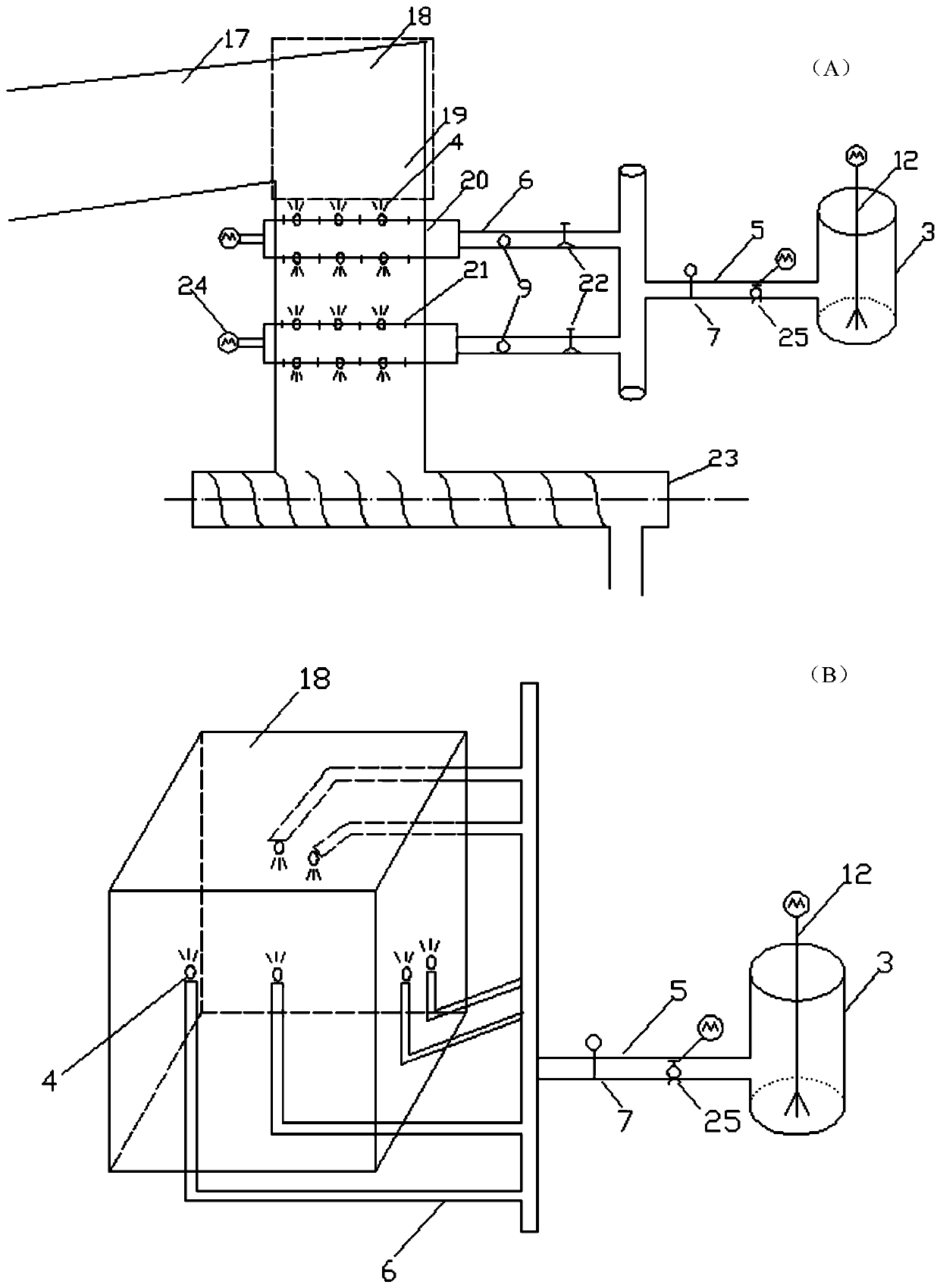

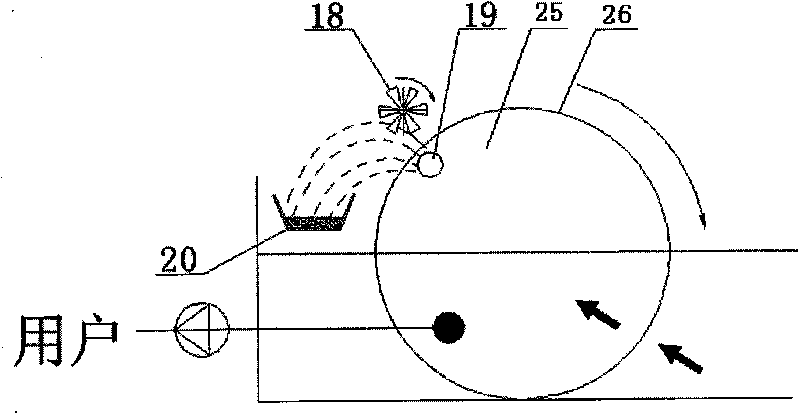

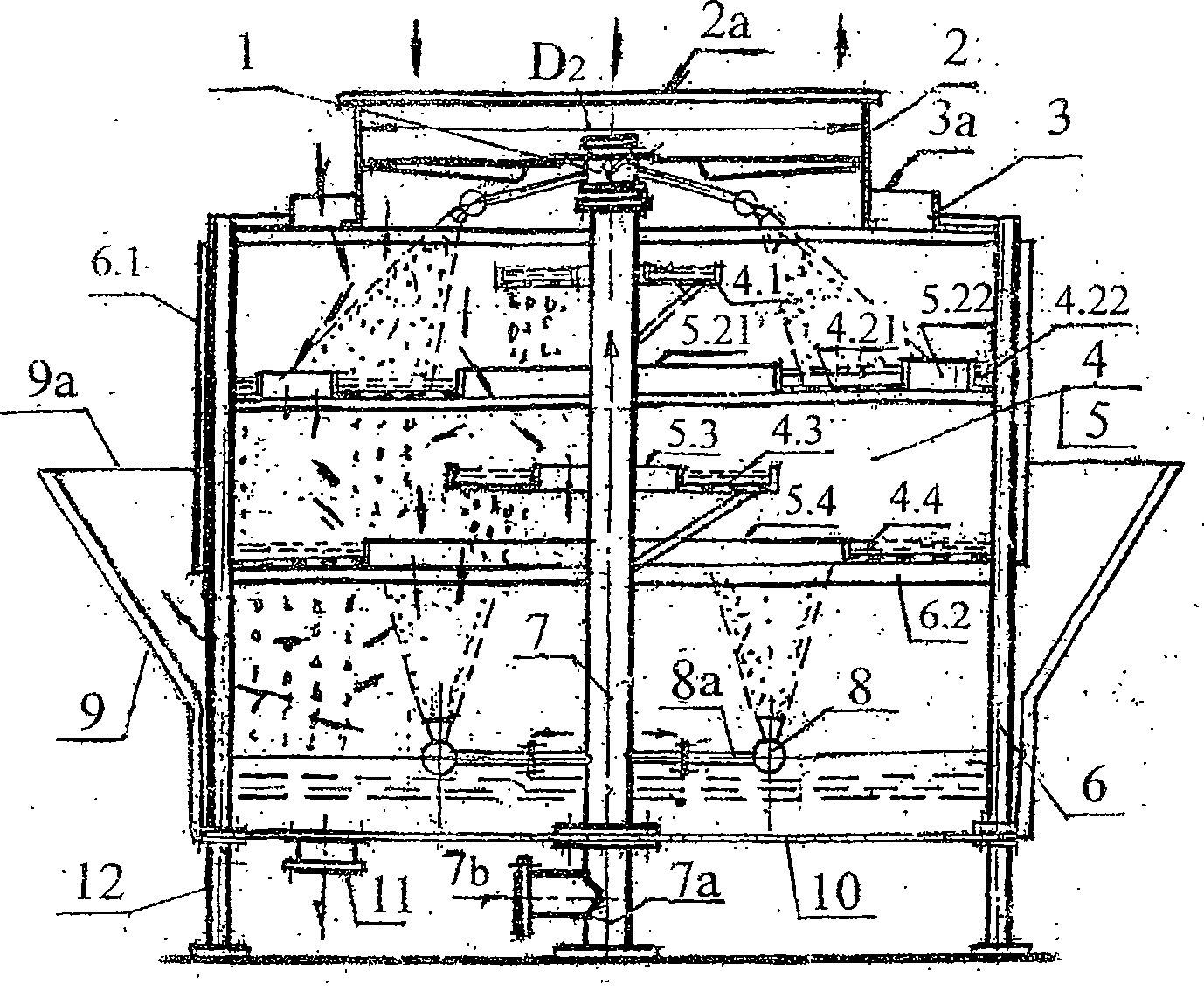

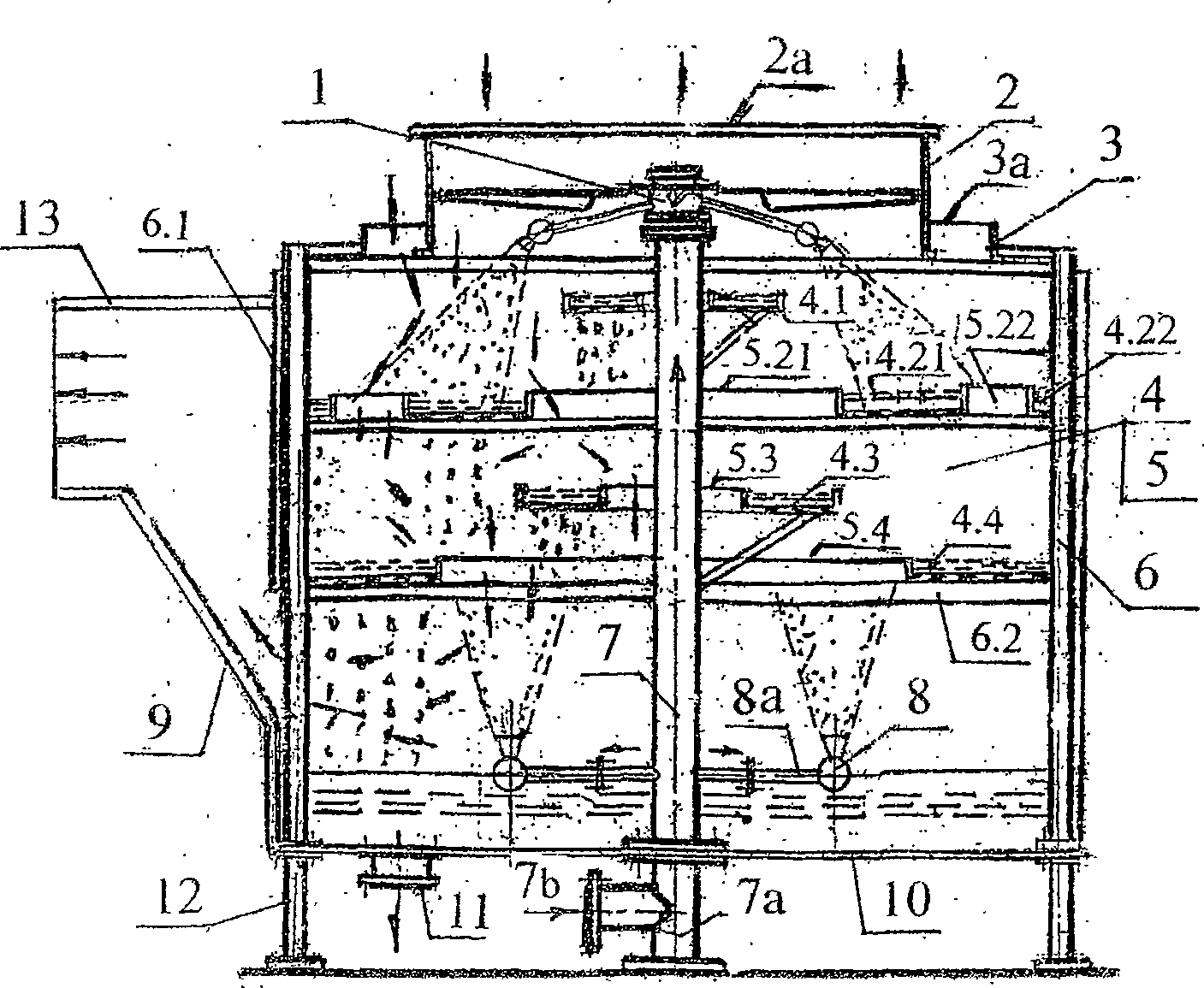

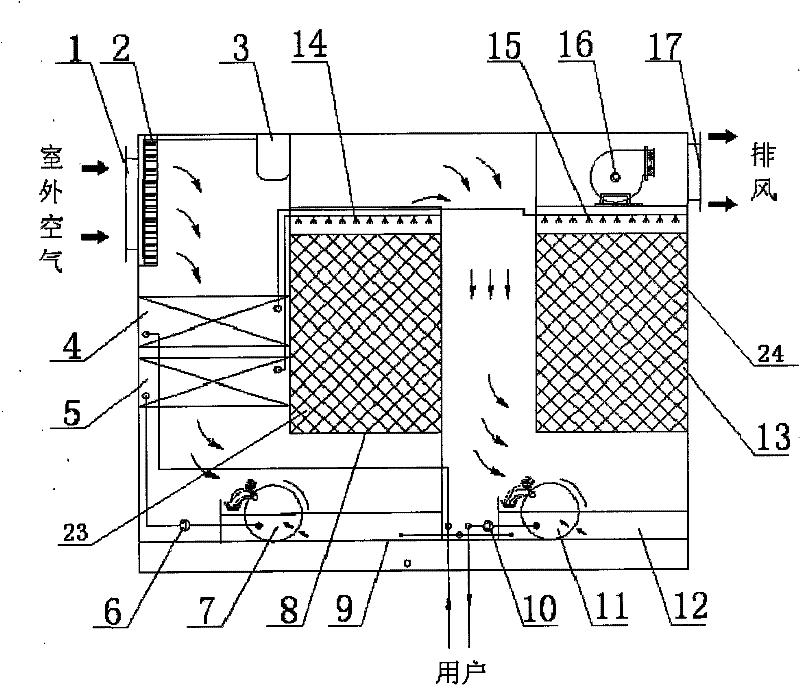

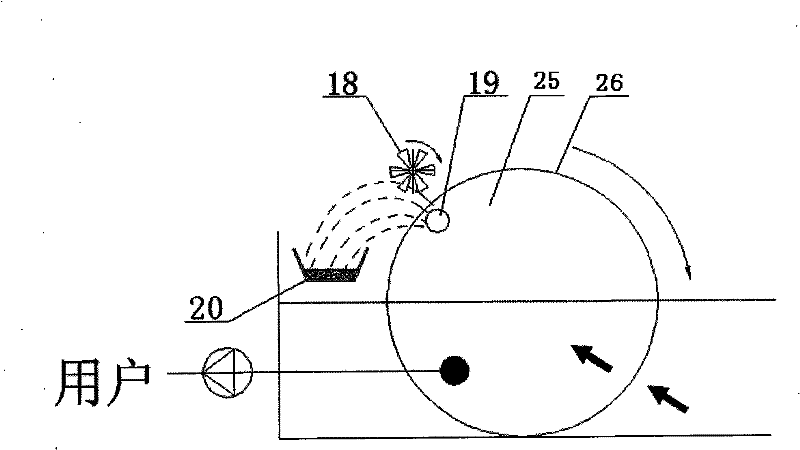

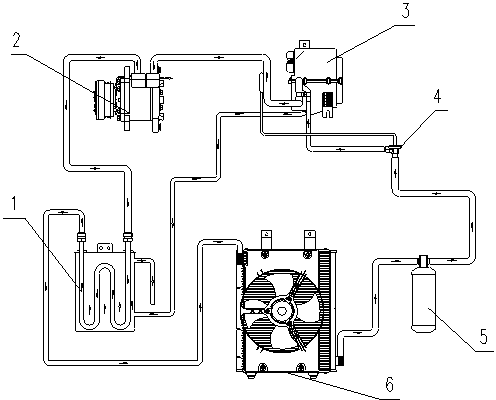

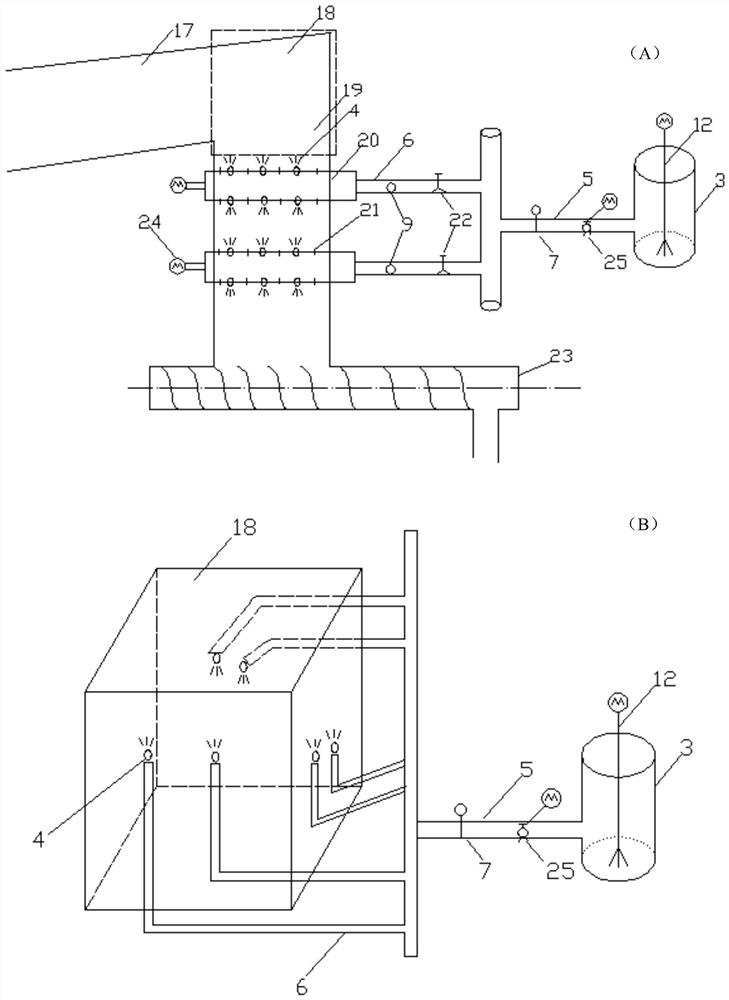

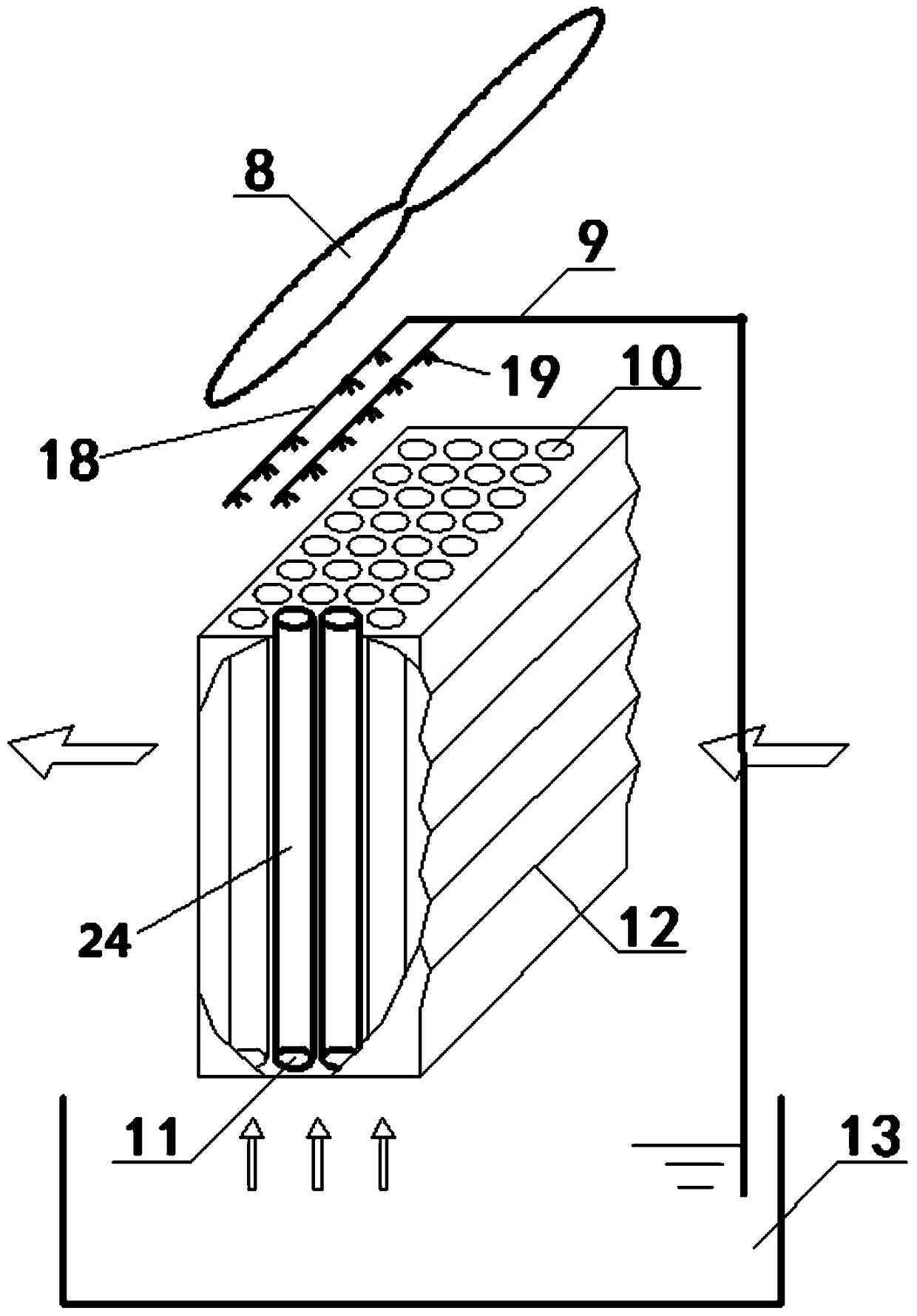

Lower jet type spraying thrust aerating and cooling tower, and jet flow cool wind machine

InactiveCN101169312AIncrease temperature dropEasy windingTrickle coolersAir conditioning systemsCooling towerEngineering

The invention relates to a downward spraying type spray boosting aeration cooling tower and shooting flow air-cooler. A tower body is provided with an out revolving type spray boosting wind pumping device inside which sprays frog flow by being connected pressure hot water, a nozzle downward sprays and laminas downward pump wind; cooling medium wind enters a wind channel for one time and two times from the tower top and a wind outlet is arranged on the middle lower part of the tower wall and is provided with a wind bucket. The lower part of the spraying device is provided with layers of drenching screen stencils, the water distribution and wind leading enable the drenching even and the cold winter passes amongst the water frog flow for a plurality of times, thereby greatly elevating the heat passing efficiency. Because the wind has the same direction with the water, the disturbance of the water frog to the laminas is reduced and the wind force of the ejection flow is increased, and the praying flow injection wind is downward and also be utilized, namely the generated three air flows of lamina mechanical wind, spray injection wind and the lamina injection wind proceed the heat exchanging with the spray flow, the wind rate is increased, the gas and water rate reaches above 1.0 which is 29 to 90 percent higher than the prior upward spraying cooling towers, and the reducing temperature can be greatly elevated. The noise of the tower water flow is reduced; the tower top has no drift ice, and the working hydraulic pressure is 0.08 to 0.12MPa. Because the wind temperature is near to the water temperature, the invention can be simultaneously used as the injection flow air-cooler, and the refrigerating air-condition in winter, summer and autumn.

Owner:魏仕英

Production method for ultralow-phosphorus hydroforming steel

ActiveCN107868900AIncrease temperature dropIncrease processing costManufacturing convertersChemical compositionNon-metallic inclusions

The invention provides a production method for ultralow-phosphorus hydroforming steel and relates to the technical field of metal material smelting. The production method sequentially comprises the steps of molten iron pretreatment, LD converter smelting, primary LF refining, slagging-off treatment, secondary LF refining, VD vacuum treatment and continuous casting. Specifically, molten iron pretreatment is carried out through a KR method; in the LD converter smelting link, peroxidation is adopted to steel tapping, the final phosphorus content is strictly controlled; in the primary LF refininglink, a slagging material is added, primary refining dephosphorization is carried out, so that the phosphorus content of molten steel reaches to 0.002%-0.003%; after the phosphorus content is qualified, slagging off is carried out; in the secondary LF refining, component adjustment is mainly carried out, and the purity degree is improved; and in VD vacuum treatment, degassing is carried out, and acasting blank is obtained through continuous casting. The HIC and SSCC performance of the ultralow-phosphorus hydroforming steel obtained through the production method can meet requirements of the related standard completely, and the chemical components of a steel plate are stable; the content of harmful chemical components of phosphorus and sulfur is low; nonmetallic inclusion is controlled well; and the quality of the casting blank is good.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

Method for improving rough rolling rhythm of strip steel

ActiveCN106424159AIncrease temperature dropImprove rolling rhythmTemperature control deviceWork cooling devicesStrip steelWater cooling

The invention belongs to the technical field of rough rolling and discloses a method for improving the rough rolling rhythm of strip steel. The method includes the steps that a rolling mill double-descaling water cooling step is adopted, and the temperature of plate blanks in the rolling process is lowered, wherein by adopting the rolling mill double-descaling water cooling step, descaling water is sprayed to the plate blanks at an inlet and an outlet of a rolling mill correspondingly. The method for improving the rolling rhythm by shortening the steel placement time is efficient and stable.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

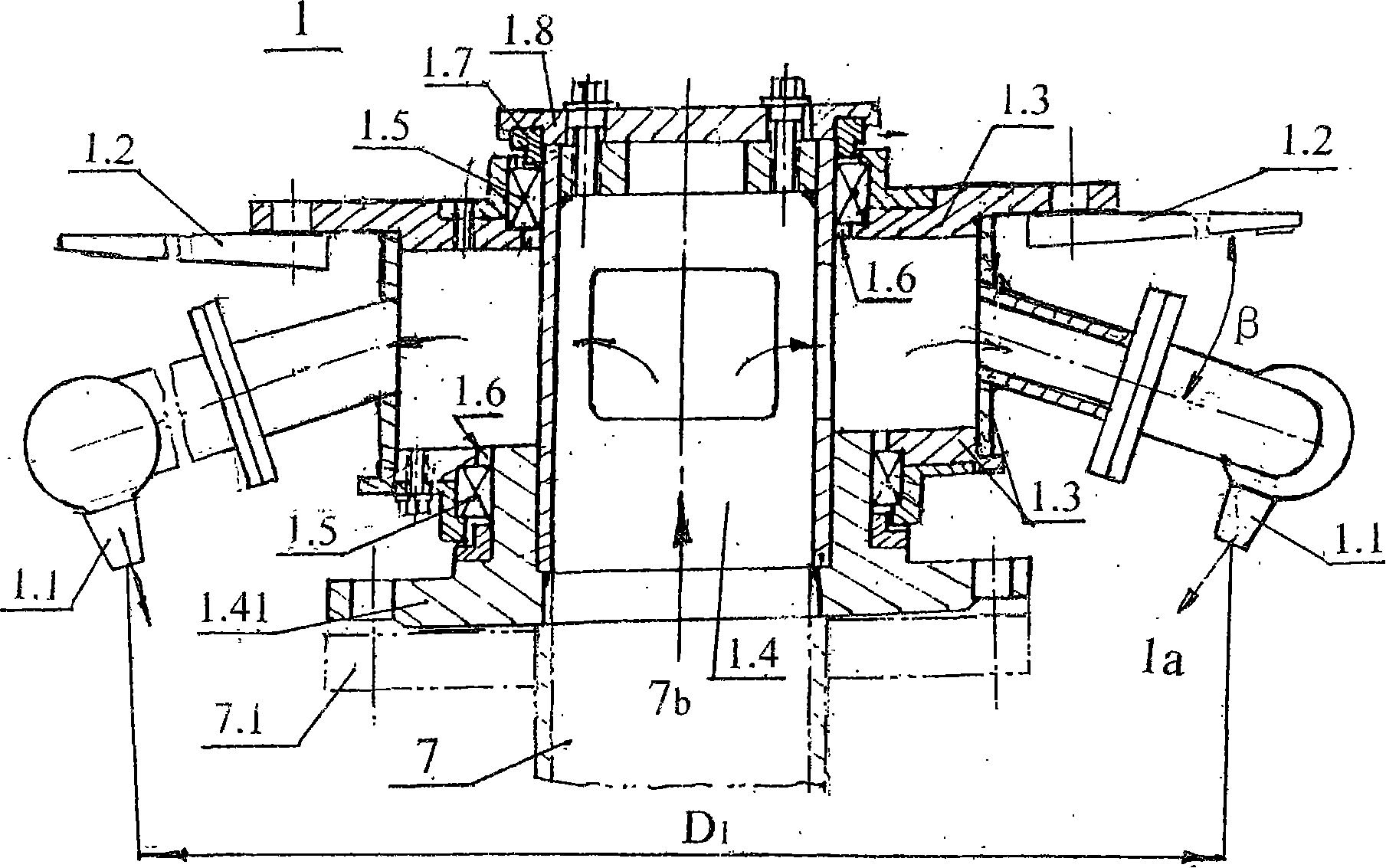

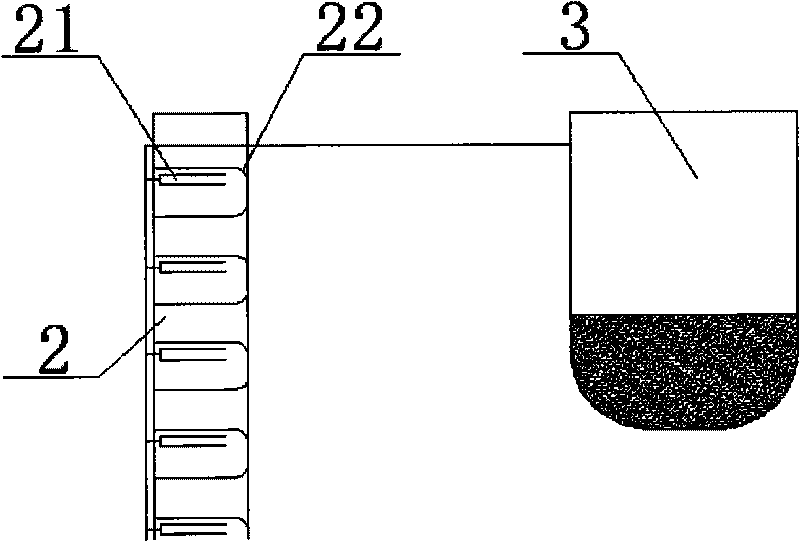

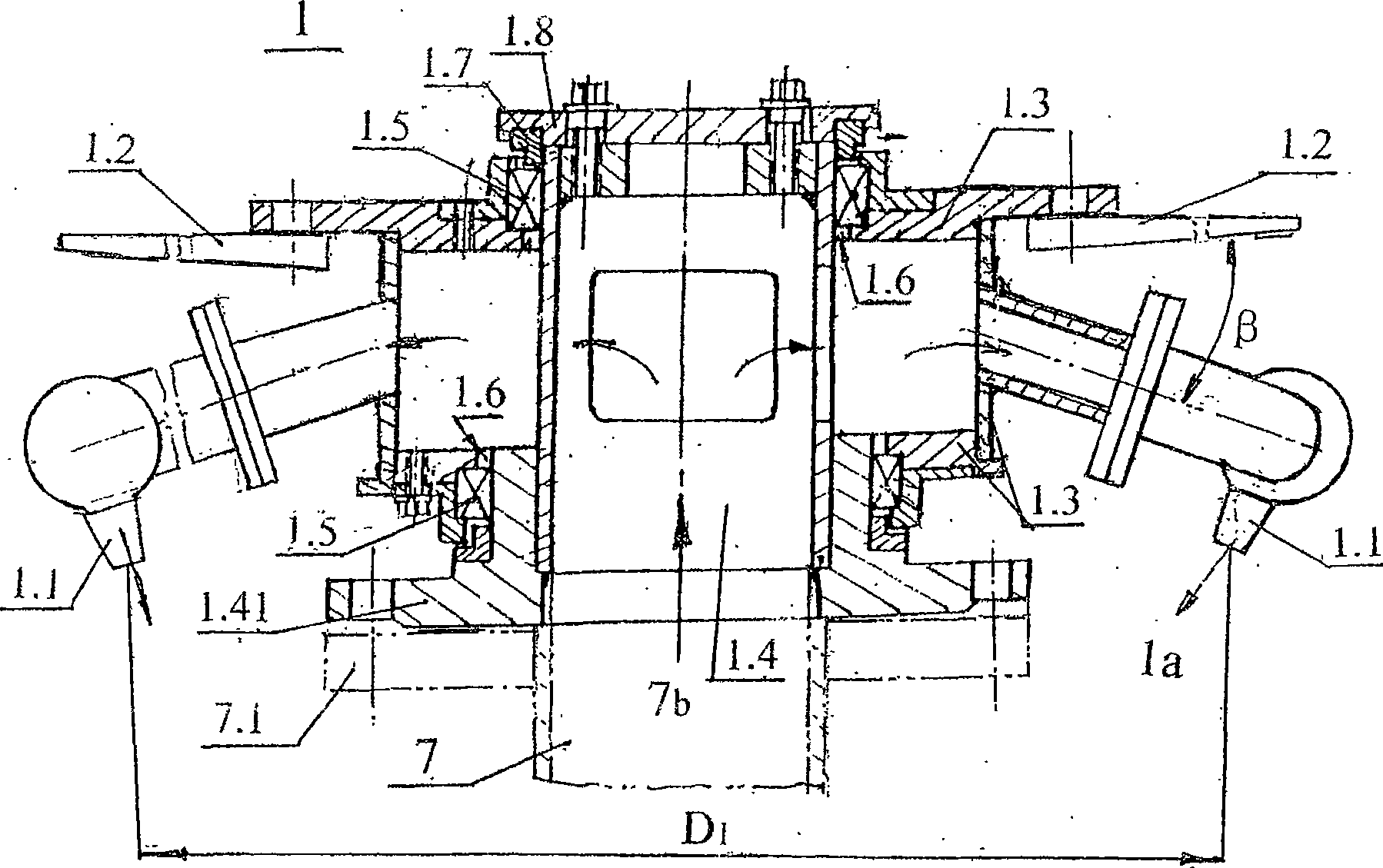

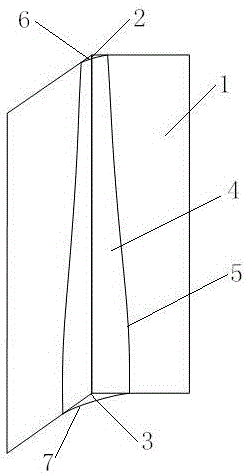

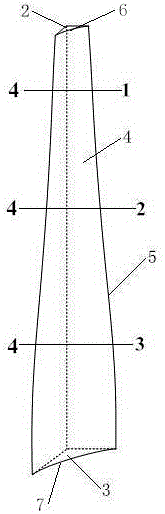

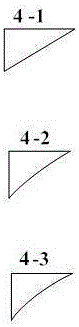

Gradual cambered chamfered mold with enhanced water cooling structure and design method

The invention belongs to the field of billet continuous casting production, and particularly relates to a gradual cambered chamfered mold with an enhanced water cooling structure and a design method. The mold is provided with four upper opening chamfers and four lower opening chamfers, wherein the chamfer angle is gradually increased according to the thermal contraction rule at the corner of a casting blank from the upper opening chamfers to the lower opening chamfers along the height direction of the inner wall of the mold; the chamfer surfaces formed between the upper opening chamfers and the lower opening chamfers are gradual cambered surfaces; the transition arc length at the boundary of the gradual cambered surfaces increases according to the air gap growth rule; the beveled edges of the upper opening chamfers on the chamber surfaces are straight or cambered; the beveled edges of the lower opening chamfers on the chamber surfaces are also straight or cambered. According to the mold, the air gap is effectively suppressed through a specific cambered chamfer structure, the heat transfer of the corner of the billet is improved, the shell growth is homogenized, the cooling of the corner of the mold is obviously improved by enhancing the water cooling structure of the chamfer region, the grains of the chamfer contact surface are thinned, and the occurrence of the corner defect is surpassed.

Owner:NORTHEASTERN UNIV

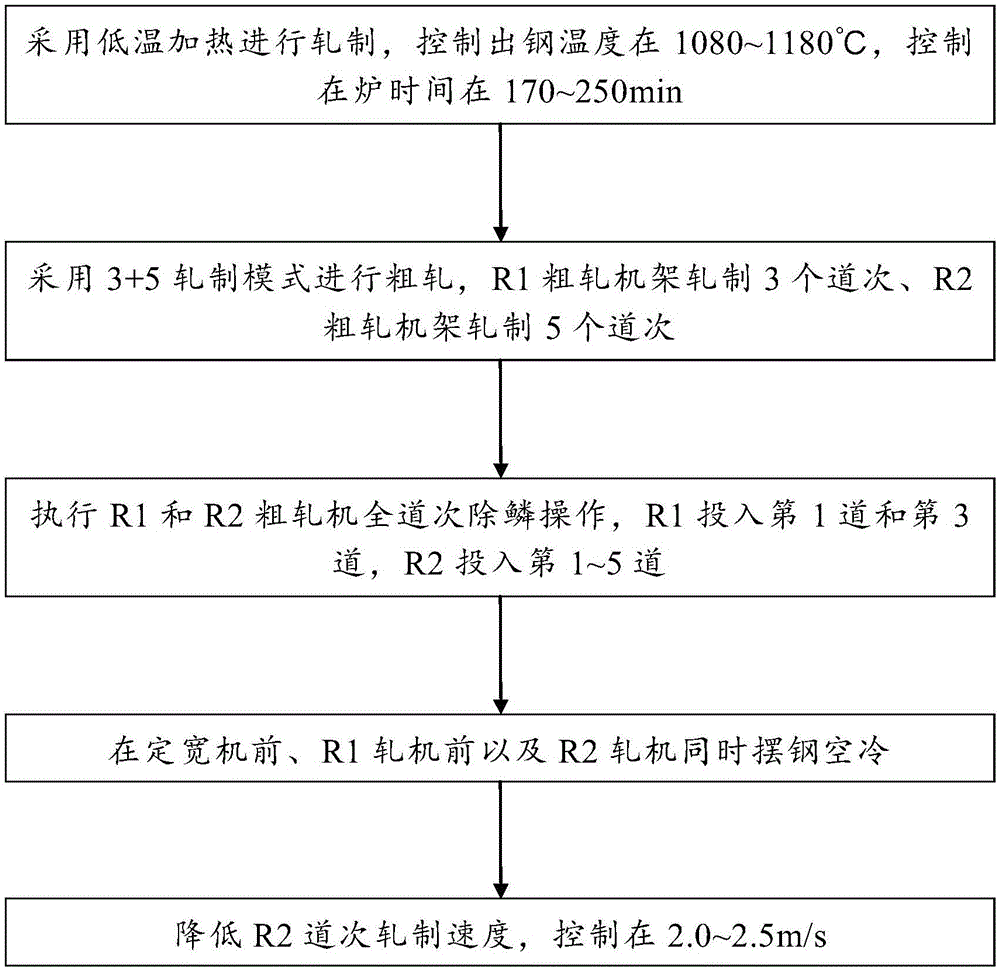

Method and device for increasing hot rolling speed of ferrite

ActiveCN106583465ALower tapping temperatureWeakening rangeTemperature control deviceWork cooling devicesRolling millRolling speed

The invention belongs to the technical field of hot rolling processes, and discloses a method for increasing the hot rolling speed of a ferrite. The method comprises the following steps of rolling by adopting a low-tempreature heating method, controlling the tapping temperature to be 1,080-1,180 DEG C, and controlling the time in the furnace to be 170-250 min; conducting rough rolling by adopting a 3+5 rolling mode, forming 3 passes through rolling of a rough mill frame R1, and forming 5 passes through rolling of a rough mill frame R2; executing all-pass scale removal operations by a rough mill R1 and a rough mill R2, putting the rough mill R1 in the first pass and the third pass, and putting the rough mill R2 in the first pass, the second pass, the third pass, the fourth pass and the fifth pass; synchronously conducting steel placing and air cooling in front of a width gauge and the rough mill R1 and on the rough mill R2; and reducing the pass rolling speed of the rough mill R2, and controlling the pass rolling speed of the rough mill R2to be 2.0-2.5 m / s.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

Novel air conditioner dehumidification unit

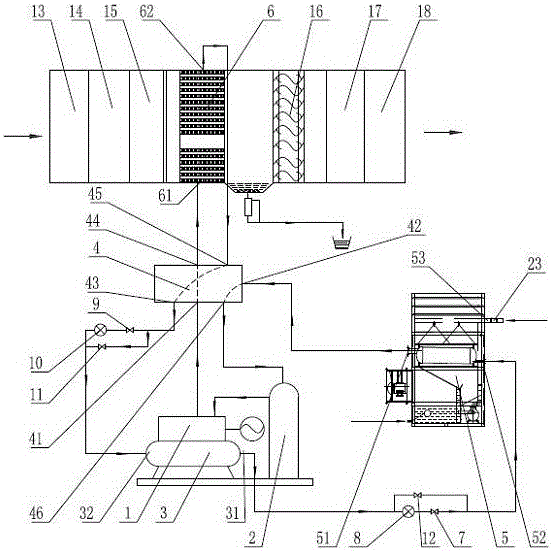

ActiveCN103307677AAchieve dehumidification functionConserve waterLighting and heating apparatusSpace heating and ventilation detailsLiquid storage tankEngineering

A novel air conditioner dehumidification unit adopts the structure that a compressor, a separating tank and a liquid storage tank are respectively connected with three ports of a reversing valve, and the other three ports of the reversing valve are respectively connected with two ports of first plate fin type heat exchangers and one end of a dew point indirect evaporative cooling device; and the other end of the dew point indirect evaporative cooling device is communicated with the liquid storage tank; the separating tank is communicated with the compressor; the first plate fin type heat exchangers are arranged on the function sections of a combined type air-handling unit; a second throttle valve is arranged on a connecting pipeline of the liquid storage tank and the reversing valve; a first throttle valve is arranged on the connecting pipeline of the dew point indirect evaporative cooling device and the liquid storage tank; in a refrigeration working condition, the second throttle valve works, and in the heating working condition, the first throttle valve works; and in field where dehumidification is required, second plate fin type heat exchangers are additionally arranged on the function sections of the combined type air-handling unit. According to the unit provided by the invention, the cold / hot water circulating system is saved, three working conditions of refrigeration, heating and dehumidification are realized, the heat exchange efficiency is high, and the remarkable effects of energy conservation and emission reduction can be achieved.

Owner:无锡金龙石化冶金设备制造有限公司 +1

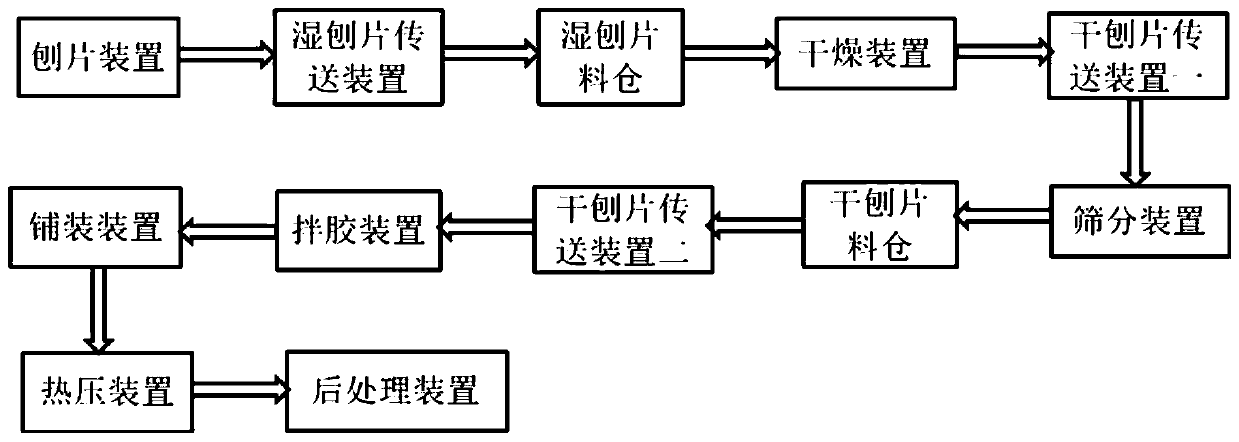

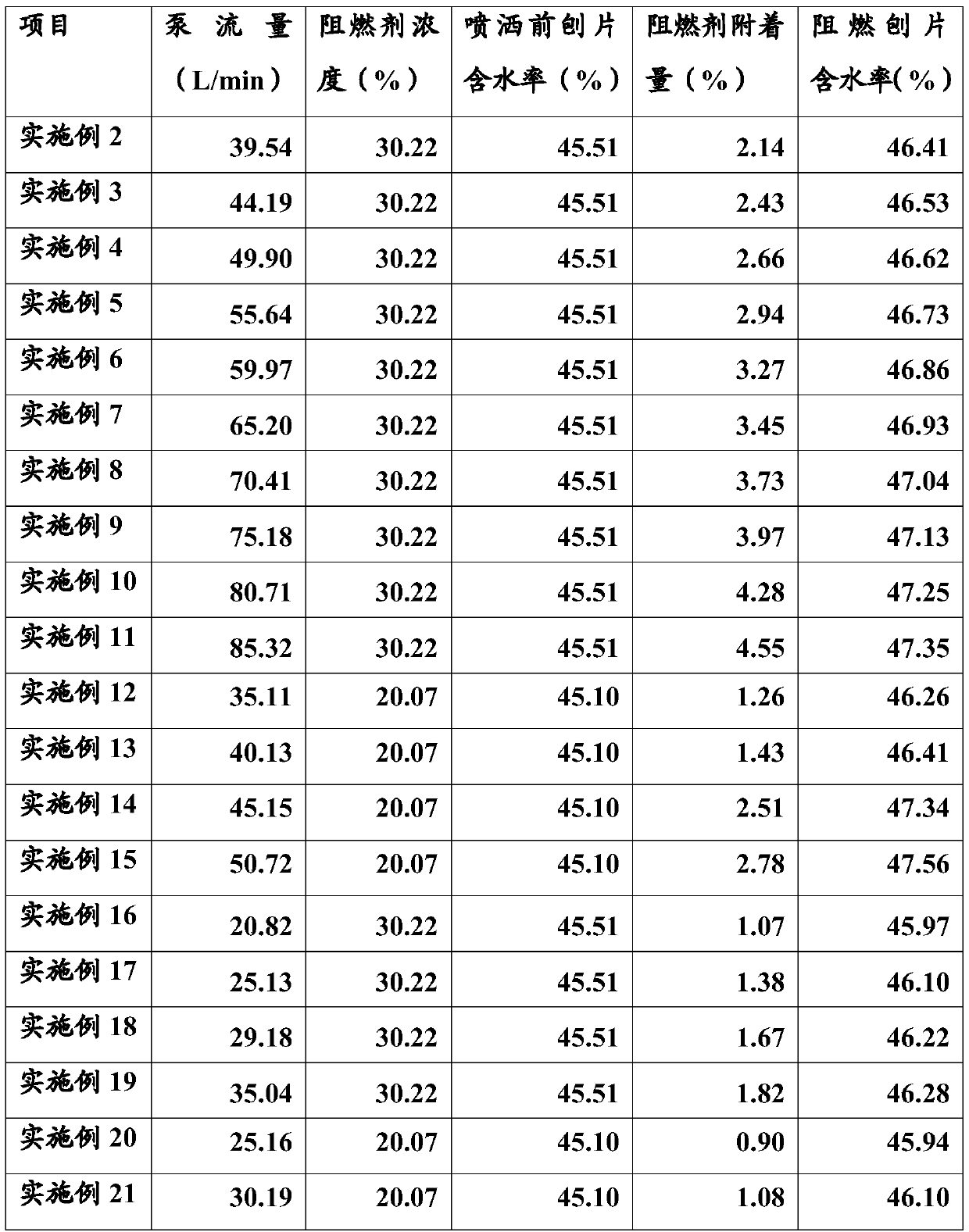

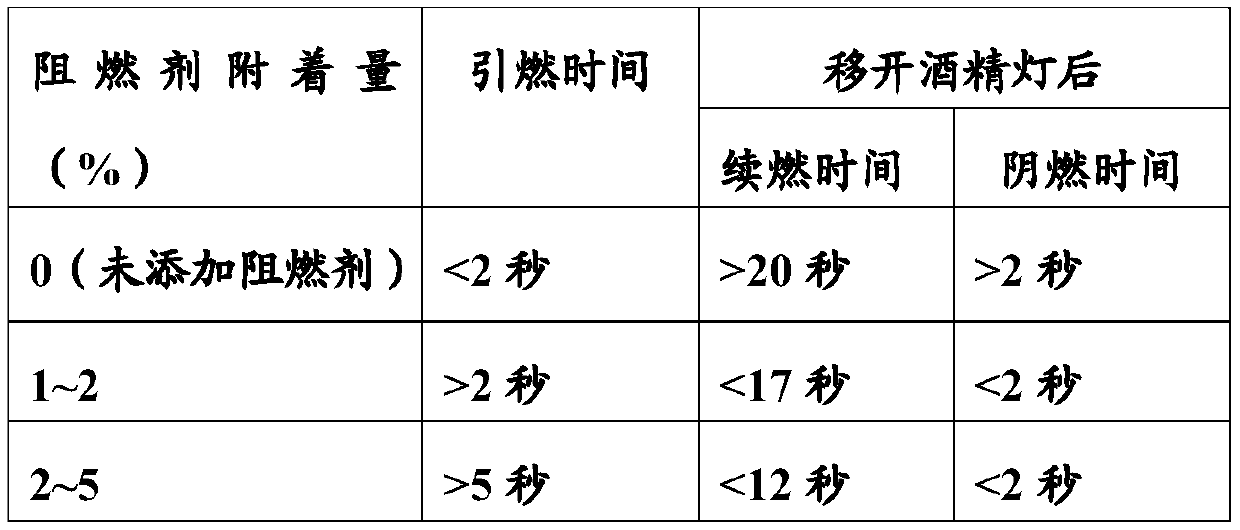

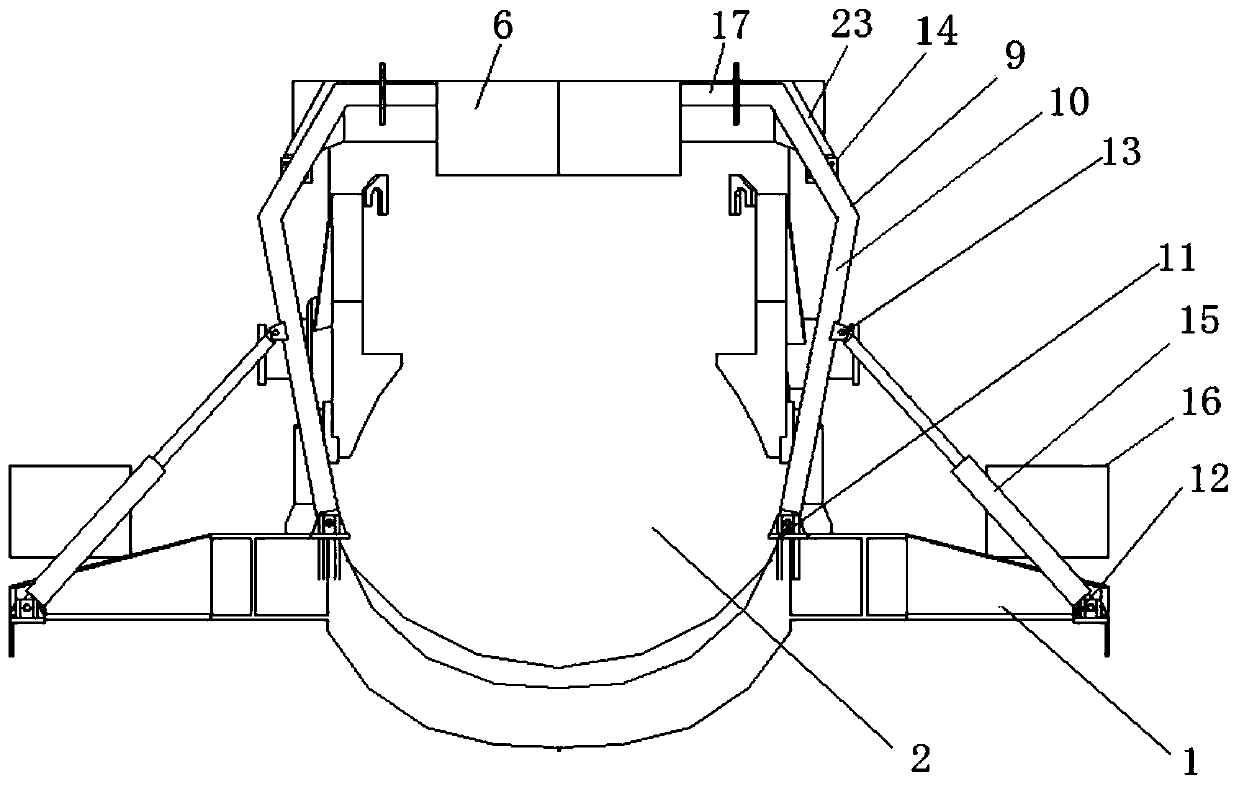

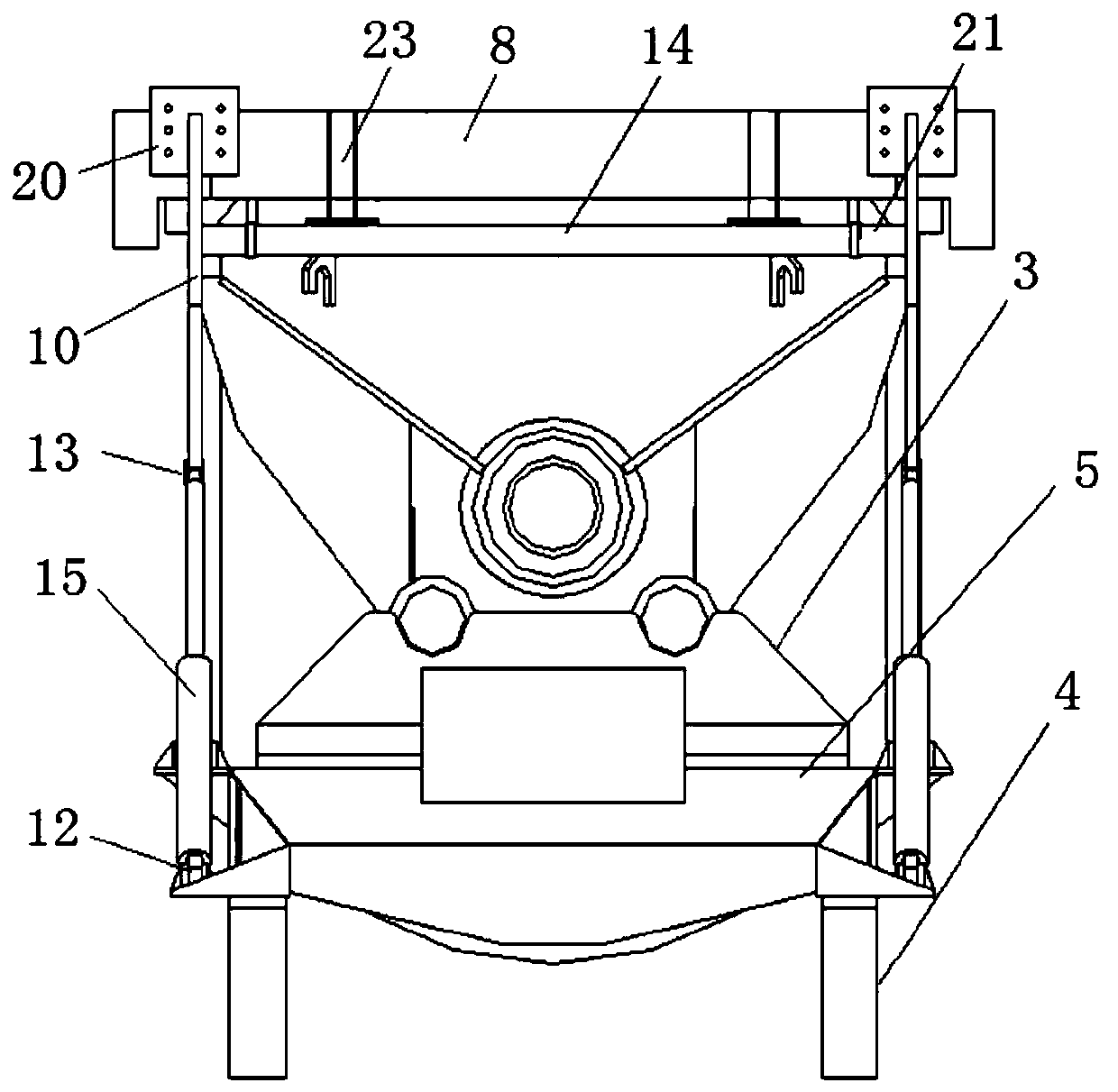

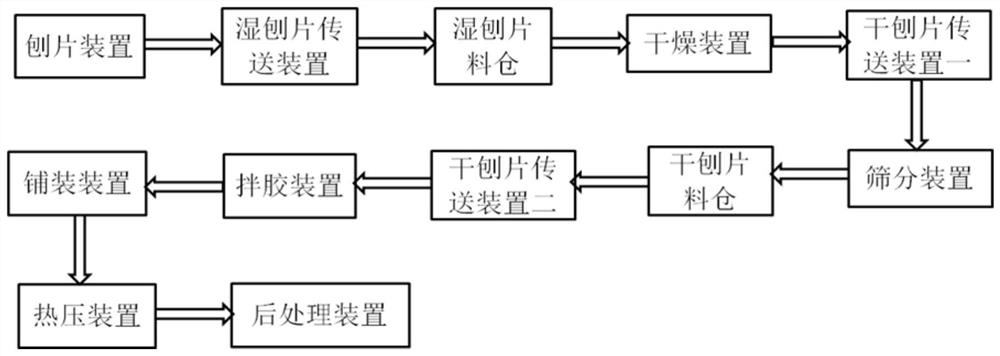

Oriented strand board production system provided with flame retarding agent spraying structure and oriented strand board production method

ActiveCN109732737AFully absorbedEvenly distributedWood working apparatusFlat articlesEngineeringFire retardant

The invention discloses an oriented strand board production system provided with a flame retarding agent spraying structure and a production method of oriented strand boards. The production system comprises a flaking device, a wet flaking conveying device, a wet flaking stock bin, a drying device, a first dry flaking conveying device, a screening device, a dry flaking stock bin, a second dry flaking conveying device, a glue stirring device, a paving device, a hot pressing device and the flame retarding agent spraying structure; and the flame retarding agent spraying structure is connected withthe flaking device, the first dry flaking conveying device and / or the second dry flaking conveying device, the glue stirring device and the paving device. Multiple-work-procedure spraying is adoptedfor the system, flaking absorbing is sufficient, and a flame retarding agent is distributed uniformly; various types of flame retarding agent solutions are sprayed while flaking is performed, an excellent flame retarding agent covering rate can be acquired unexpectedly, and the temperature lowering amplitude of a knife ring and a blade is further improved. A flame retarding oriented strand board obtained due to treatment is good in flame retarding performance; and the physical performance of the obtained oriented strand board is equivalent to that of an oriented strand board produced and pressed without adding a flame retarding agent.

Owner:湖北宝源木业有限公司

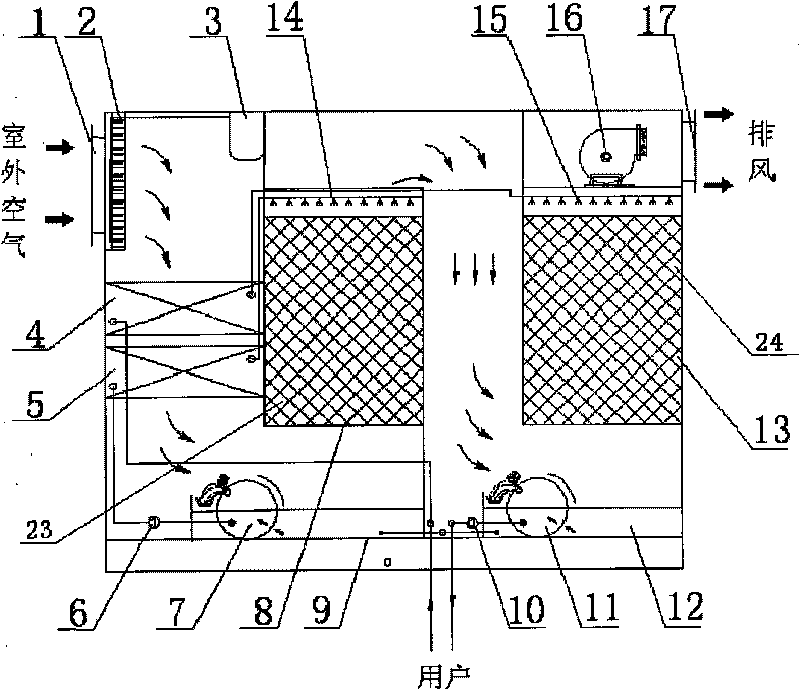

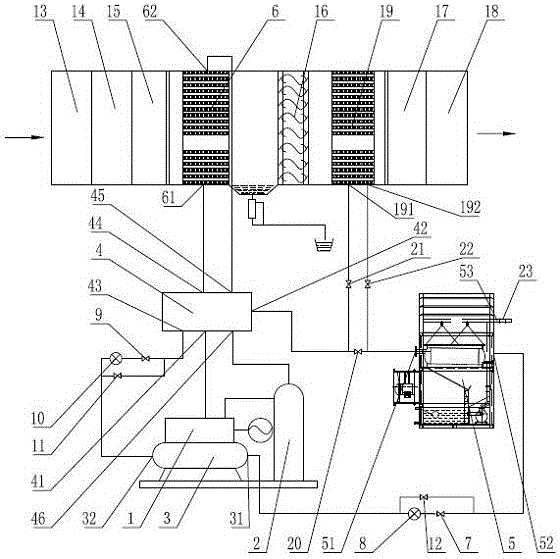

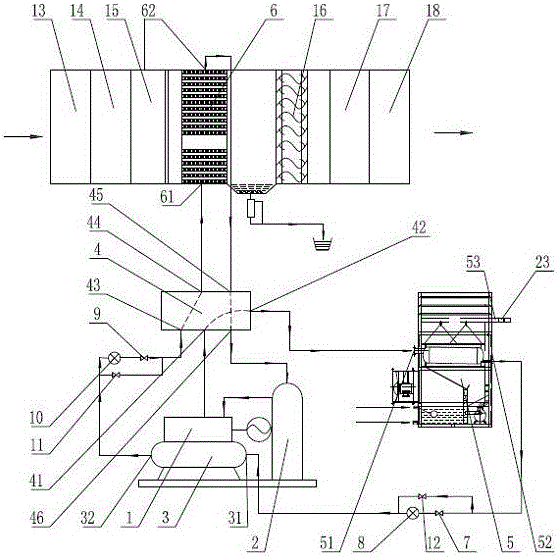

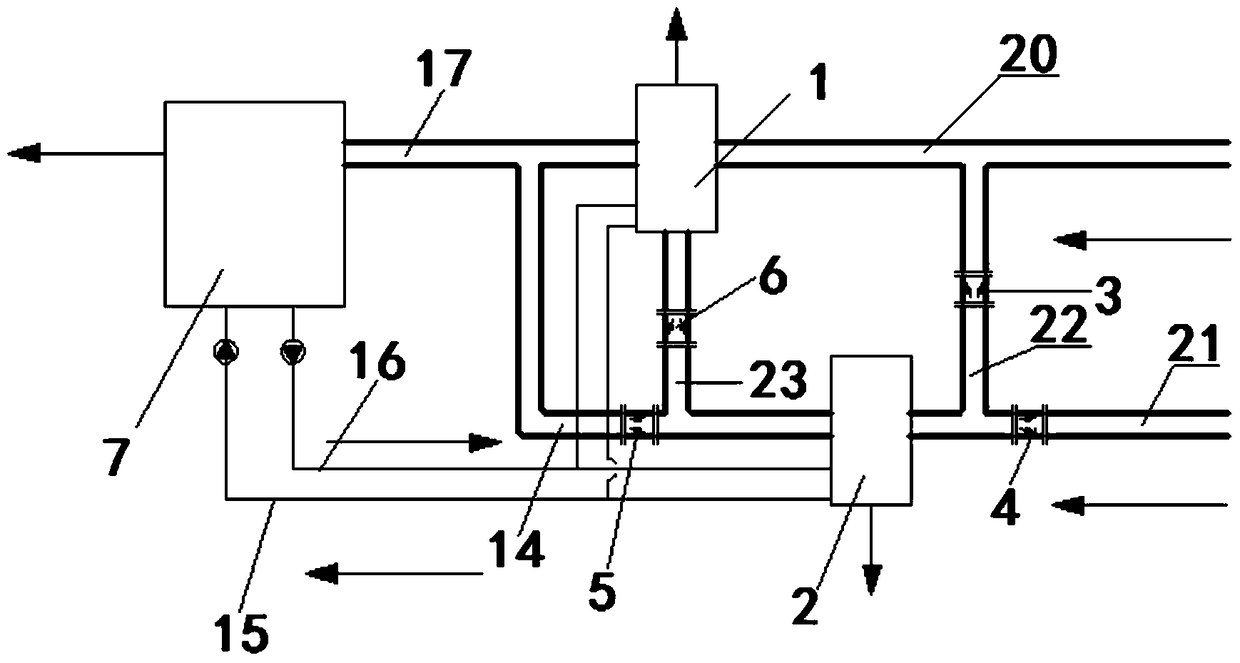

Evaporative water chilling unit comprising parallel air coolers, air filter and water filter

InactiveCN101713580AImprove the coefficient of performanceImprove efficiencyEnergy recovery in ventilation and heatingLighting and heating apparatusEvaporative coolerWater filter

The invention discloses an evaporative water chilling unit comprising parallel air coolers, an air filter and a water filter, wherein a primary direct evaporative cooler and a secondary direct evaporative cooler which are connected in parallel are arranged in a shell of the unit, and a primary air cooler and a secondary air cooler which are connected in parallel are also arranged in the shell of the unit; an air filtering and dust removing device is arranged at one side of the primary direct evaporative cooler; an exhaust fan is arranged at one side of the secondary direct evaporative cooler; and a water collecting box and the water filter are respectively arranged at the lower parts of the two direct evaporative coolers. The water chilling unit of the invention adopts the mode of arranging the primary air cooler and the secondary air cooler in parallel and arranging the primary direct evaporative cooler and the secondary direct evaporative cooler in parallel, and simultaneously, the active air filter and the active water filter are arranged for two-stage filtration; the evaporative cooling technology is fully utilized to prepare high-temperature cold water of which the temperature is between wet-bulb temperature and dew-point temperature; and compared with the traditional water chilling unit refrigerated mechanically, the evaporative water chilling unit of the invention is more economic, energy-saving and environment-friendly and has higher coefficient of performance (cop).

Owner:XI'AN POLYTECHNIC UNIVERSITY

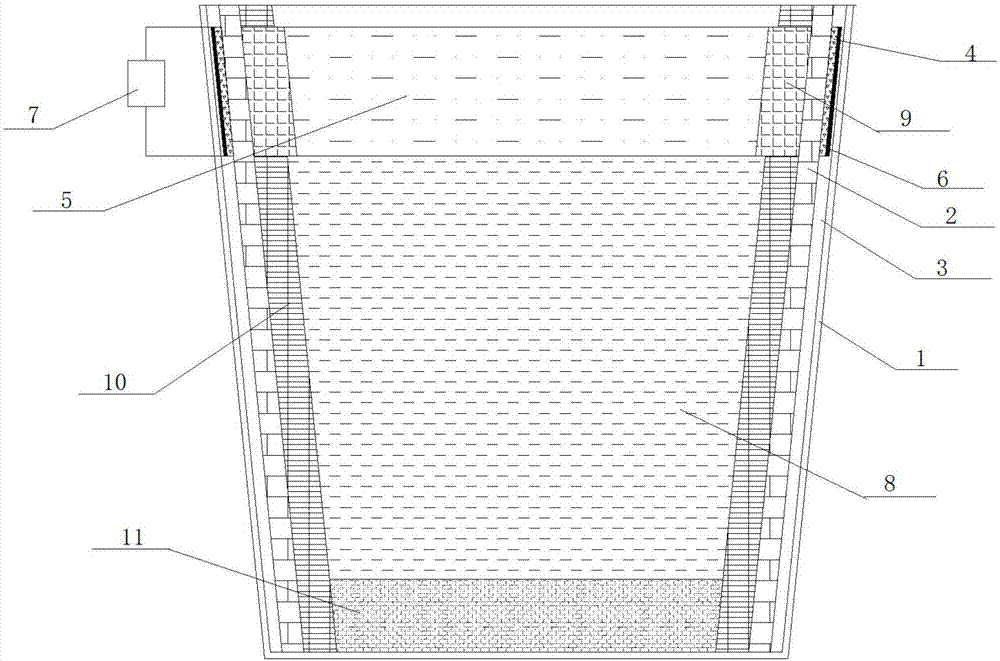

Control device and control method for refining ladle slag emulsification

The invention discloses a control device for refining ladle slag emulsification. The control device comprises a furnace body; a wall surface of the furnace body comprises a fire-resistant layer, a furnace body permanent layer and a thermal insulation layer that are arranged from the inside to the outside sequentially; a brick cup layer is arranged at the bottom of the furnace body; the thermal insulation layer and the brick cup layer are externally provided with wrapping steel wrapping the whole furnace body; the fire-resistant layer comprises a molten steel fire-resistant layer part located at the lower part of the furnace body and a slag line fire-resistant layer part located at the upper part of the furnace body; a coil is arranged the corresponding upper parts of the thermal insulation layer and the slag line fire-resistant layer; and the two ends of the coil are connected with an anode and a cathode of a direct current power supply. The invention further discloses a control method for the refining ladle slag emulsification. The control method is characterized in that molten steel and slag are poured into furnace body, argon gas is blown in from the bottom of the furnace body for 1-3mins, then the direct current power supply is turned on, the coil is electrified, and an electromagnetic field is formed. An emulsification motion state of the slag is controlled in real time under a dynamic condition, so that the life of a liner material is prolonged effectively, the steel cleanness is improved, and a guarantee is provided for safe and efficient production of high quality steel.

Owner:WUHAN UNIV OF SCI & TECH

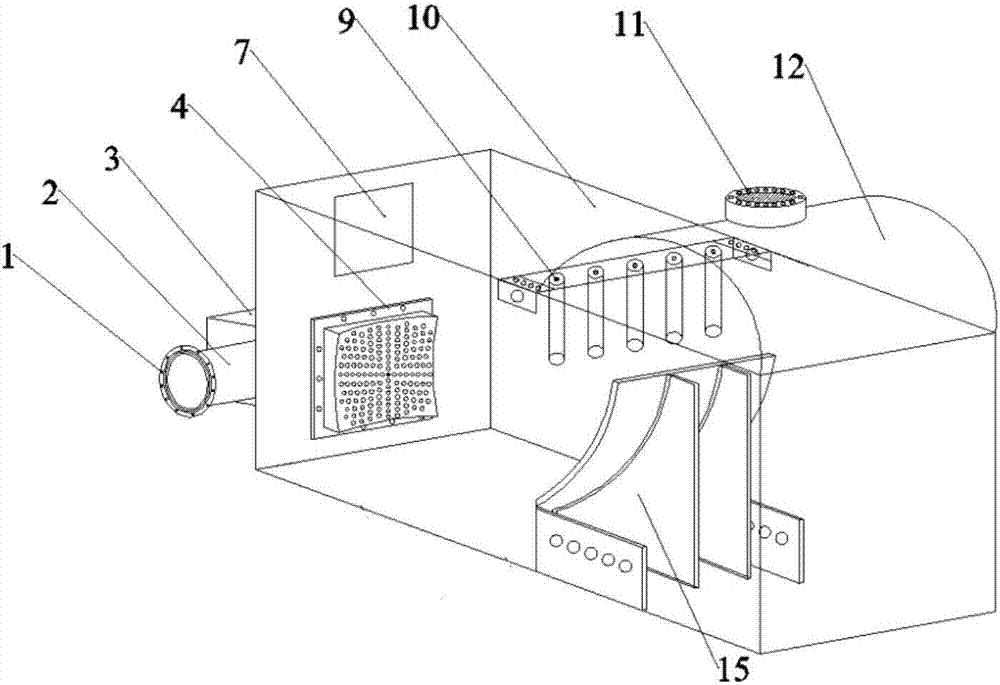

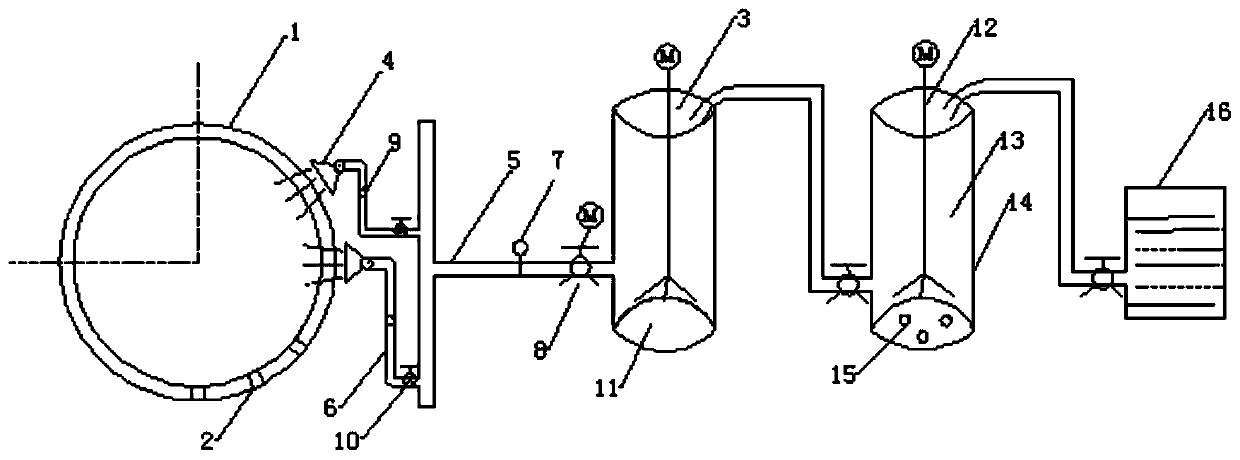

Ultrasonic punching device for blast furnace slag

ActiveCN107058654AAvoid cloggingSpeed up heat exchangeRecycling and recovery technologiesPunchingSlag

The invention relates to an ultrasonic punching device for blast furnace slag. A flushing tank body is located below a slag inlet. A water tank body is provided with a water inlet pipe, and the water inlet pipe is connected with an externally-connected water pipe. The flushing tank body is connected with a punching pore plate with punching nozzles. A slag flushing ditch is formed between a left-side retaining wall and a right-side retaining wall. The slag flushing ditch is provided with an inclined section and a gentle section. A cambered surface top covering plate is arranged on the rear section of a punching device body. A waste gas collection device is arranged on the cambered surface top covering plate. Amplitude-change poles of an ultrasonic generation device are connected to the left-side retaining wall and the right-side retaining wall. A flow distribution device is mounted on the gentle section of the slag flushing ditch. Flow distribution partitions are arranged on an arc-shaped baffle of the flow distribution device. By means of the ultrasonic punching device for the blast furnace slag, the blast furnace slag enters the slag flushing ditch from the slag inlet, flushing water enters the slag flushing ditch from the punching nozzles in a gathered manner, the flow distribution of the water granulated slag stream is conducted through the flow distribution device and the ultrasonic generation device, and the generation of foaming slag is inhibited; and the granularity of the water granulated slag is uniformized, harmful gas such as SOx and H2S is absorbed effectively, and waste gas is collected and treated by a waste collection device and then discharged. The ultrasonic punching device is simple in structure and environmentally friendly.

Owner:WUHAN UNIV OF SCI & TECH

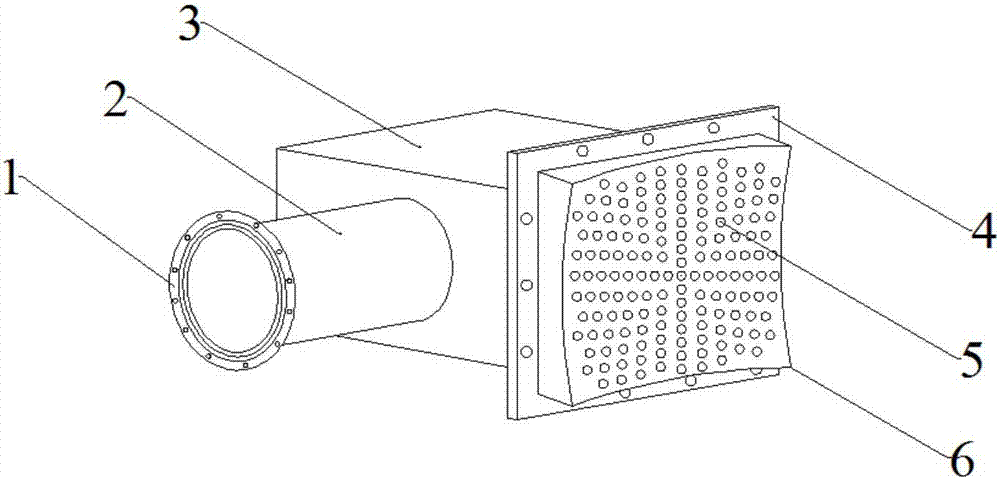

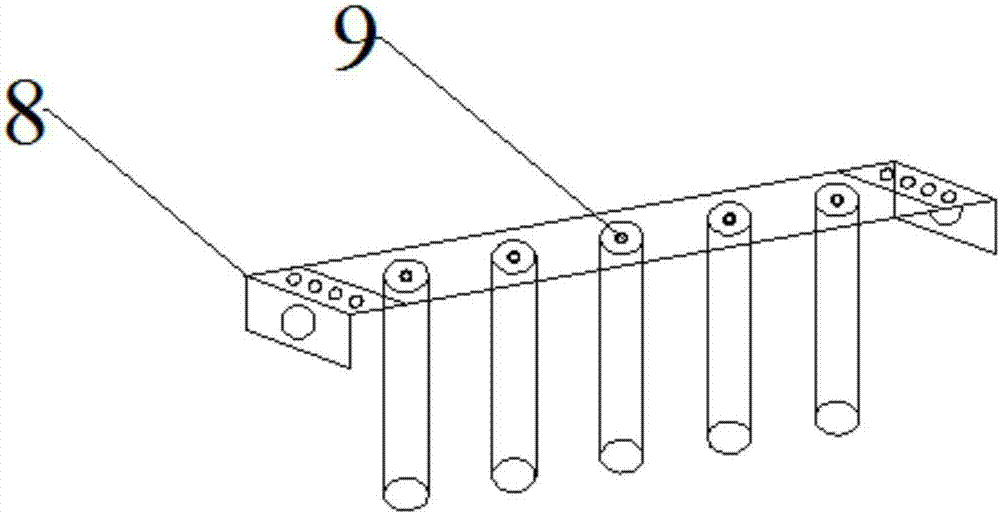

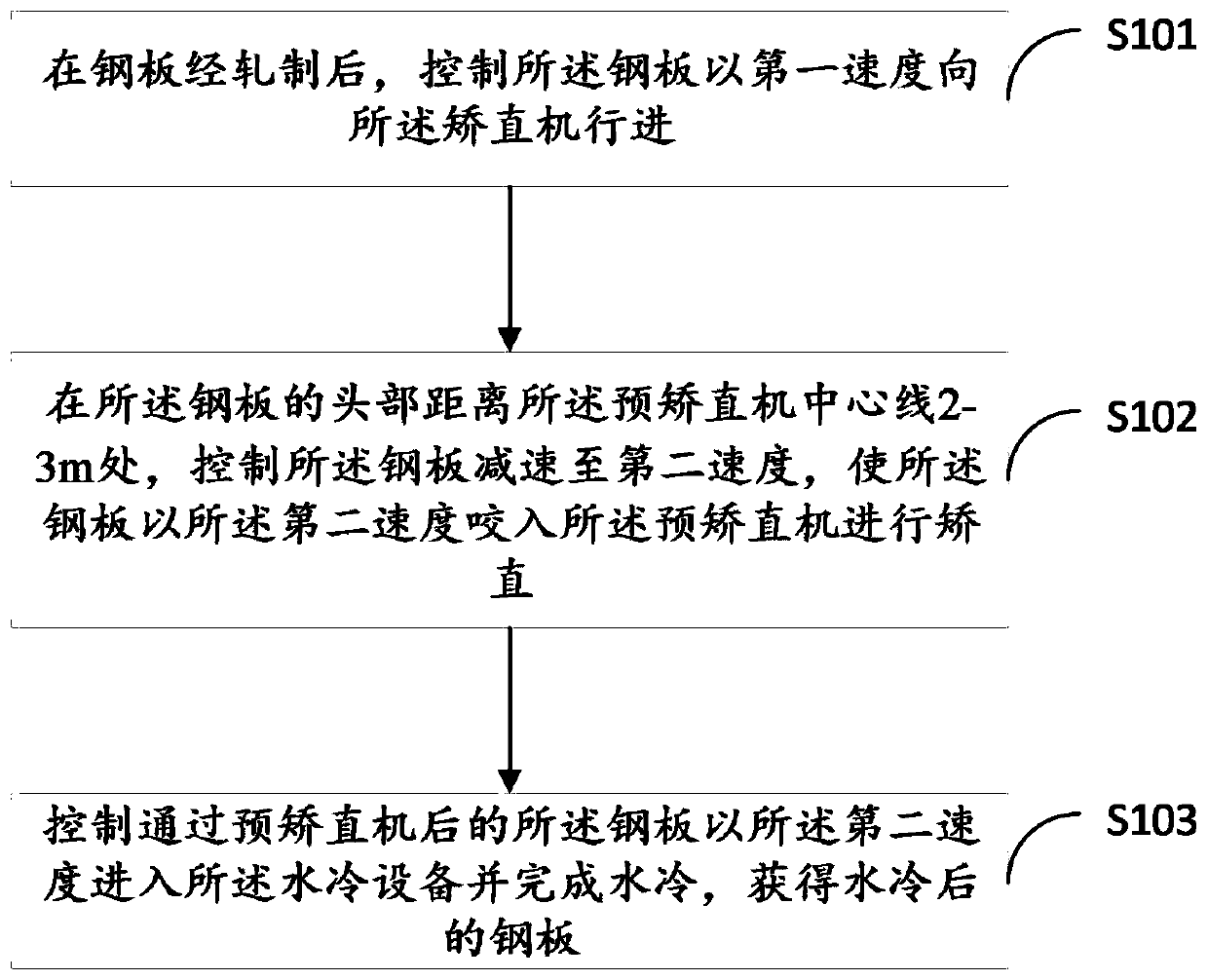

Method and system for improving water cooling quality of TMCP steel plate

InactiveCN110842033AQuality improvementIncrease temperature dropTemperature control deviceWork cooling devicesPhysicsSteel plates

The invention discloses a method and system for improving the water cooling quality of a TMCP steel plate. The method and system are used for a TMCP production line. A pre-straightening machine is mounted on an inlet of water cooling equipment in the TMCP production line. The method comprises the steps that after the steel plate is rolled, the steel plate is controlled to advance towards the pre-straightening machine at first speed; the speed of the steel plate is controlled to be reduced to second speed at the position where the distance between the head of the steel plate and the center lineof the pre-straightening machine ranges from 2 m to 3 m, so that the steel plate enters the pre-straightening machine to be straightened at the second speed; and the steel plate passing through the pre-straightening machine is controlled to enter the water cooling equipment at the second speed, water cooling is completed, and the steel plate obtained after water cooling is obtained. The technicalproblem that in an existing TMCP, the water cooling quality of the steel plate is poor is solved.

Owner:SHOUGANG CORPORATION

Indirect evaporative condensing unit

PendingCN112984658AReduce the temperatureReduce energy consumptionCondensate preventionLighting and heating apparatusEvaporative coolerCondensation temperature

The invention discloses an indirect evaporative condensing unit. The indirect evaporative condensing unit comprises a direct evaporative cooling unit, indirect evaporative cooling units symmetrically arranged on the left side and the right side of the direct evaporative cooling unit, and a condenser arranged below the direct evaporative cooling unit; air inlets leading to the interior of the direct evaporative cooling unit are further formed in the sides, close to the direct evaporative cooling unit, of the indirect evaporative cooling units; the two air inlets communicate with primary air outlets of the indirect evaporative cooling units on the corresponding sides of the two air inlets correspondingly; and an air inlet a is further formed in the side, away from the direct evaporative cooling unit, of each indirect evaporative cooling unit. According to the indirect evaporative condensing unit, the vertical pipe type indirect evaporative cooler is adopted for precooling air entering the unit, the temperature of the air entering the condenser is reduced, and therefore the condensing temperature is effectively reduced, energy consumption of a compressor is reduced, and the problems that a traditional air cooling refrigerant air conditioner is prone to being shut down at the high temperature in summer, and power consumption of the compressor is large are solved.

Owner:新疆华奕新能源科技有限公司

Method for rolling interstitial free steel ferrite on traditional hot rolling mills

ActiveCN101618396BImprove deep drawing performanceImprove organizational structureTemperature control deviceWork treatment devicesLaminar coolingHeating furnace

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

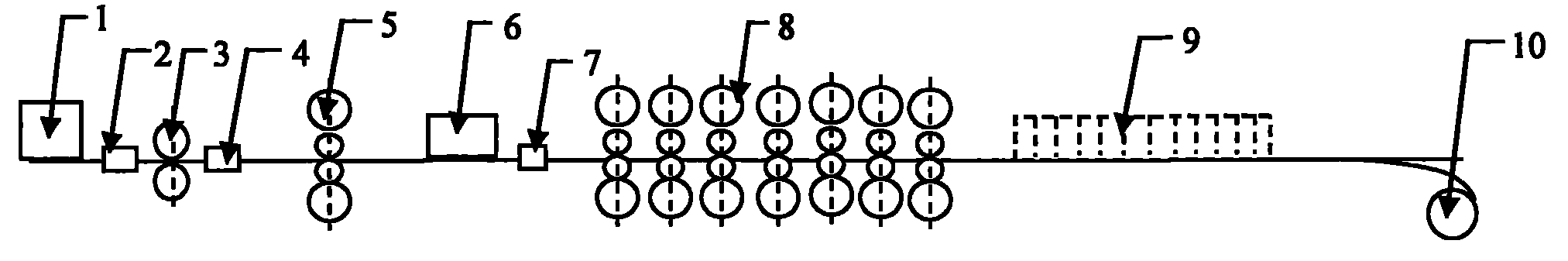

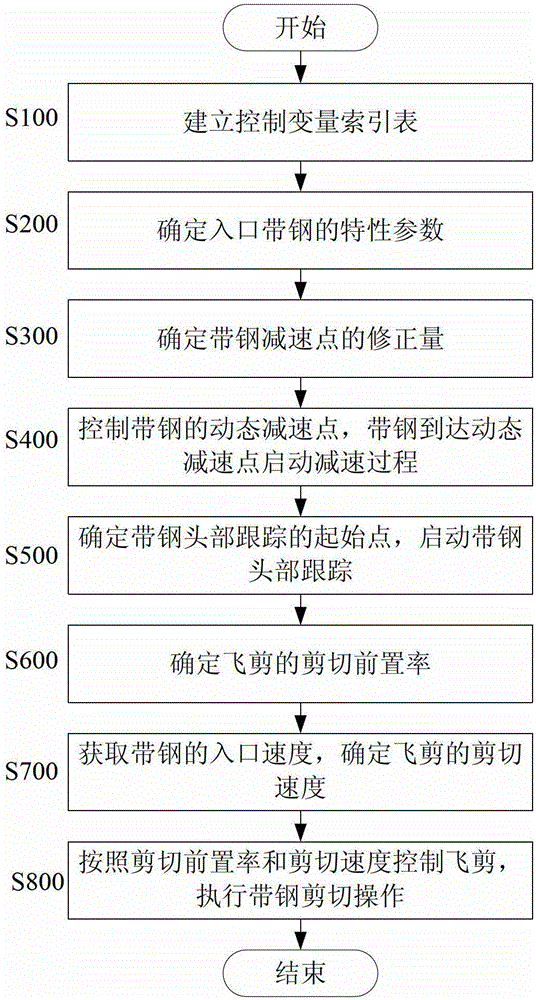

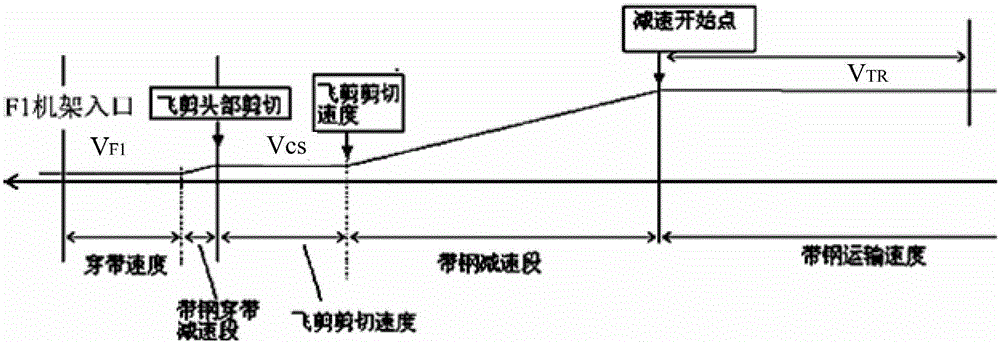

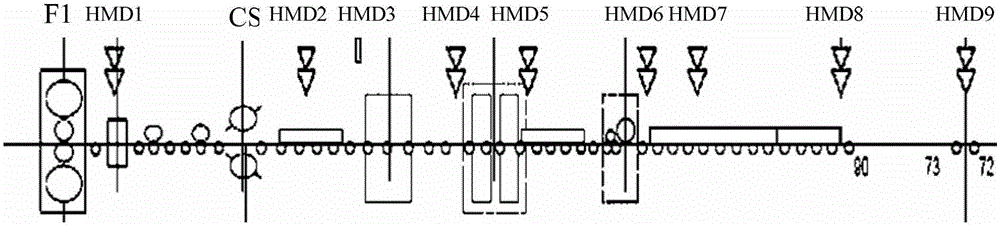

A method for controlling the variable speed at the finish rolling entrance of hot continuous rolling mill

ActiveCN103934276BRealize multi-level controlSave shipping timeRoll mill control devicesMetal rolling arrangementsStrip steelContinuous rolling

The invention provides a hot continuous rolling mill finish rolling inlet variable speed control method which is especially suitable for metal rolling mills or control devices for machining products, and particularly relates to a method for controlling entrance speed of finish rolling strip steel of a hot continuous rolling mill through computer programs. According to four sets of compensation factors, feature parameters of the entering strip steel are determined; according to the feature parameters of the strip steel, speed reducing point correction of the strip steel is determined; according to the speed reducing point correction, a target speed reducing point of the strip steel is determined, and a dynamic speed reducing point is controlled; according to the target speed reducing point of the strip steel, a tracking start point of the head of the strip steel is determined; according to the feature parameters of the strip steel, the shear front-arranging rate of a flying shear is determined; according to the entrance speed of the strip steel and the shear front-arranging rate of the flying shear, the shearing speed of the flying shear is determined. Speed change points are determined according to the types and specifications of steel, the speed of the strip steel before flying shear is controlled in a multilevel mode, conveying time of the strip steel in an intermediate roller way is saved, the rolling efficiency of different strip steel can be maximized, and the rolling efficiency of the strip steel in the hot rolling process is improved.

Owner:BAOSHAN IRON & STEEL CO LTD

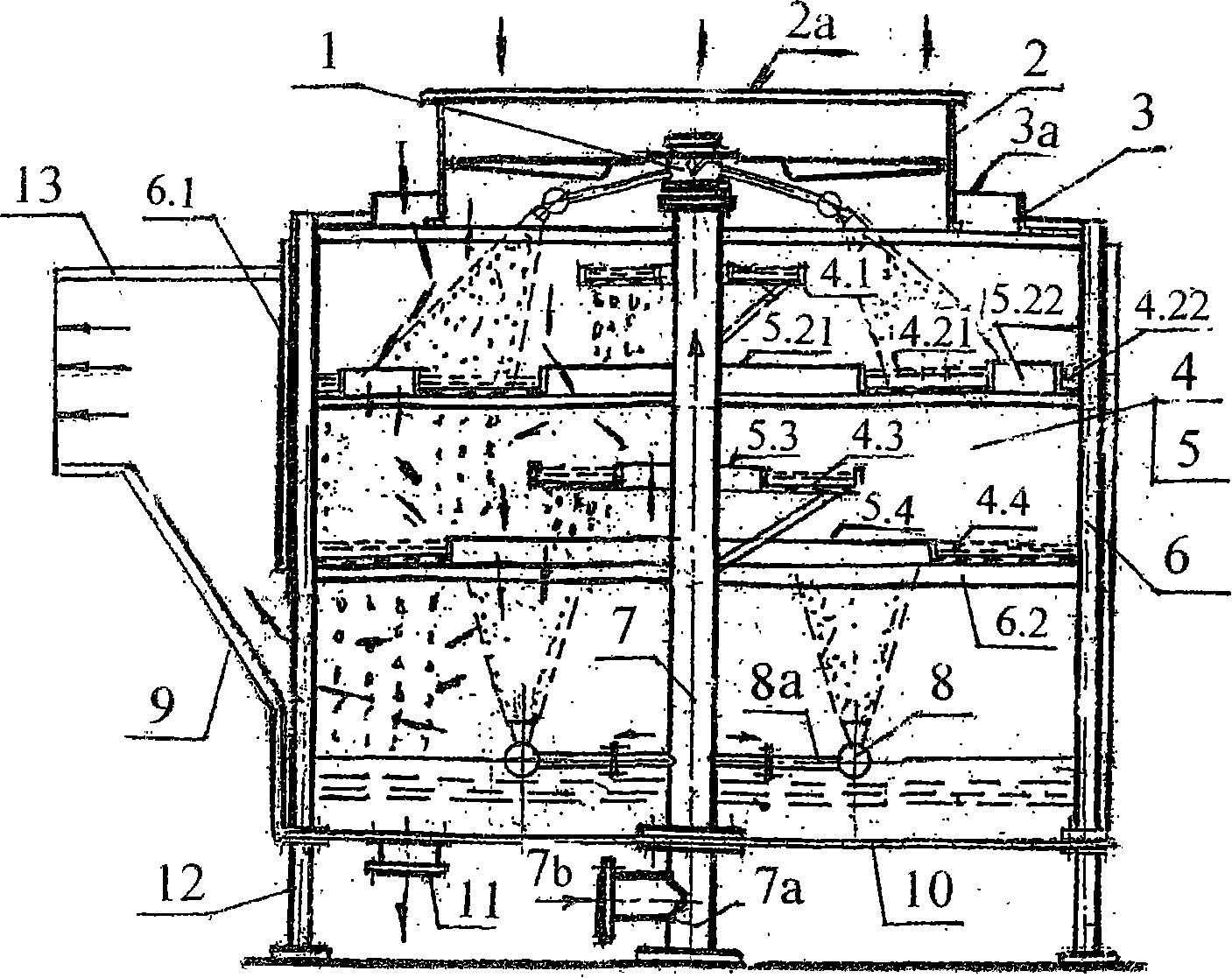

Lower jet type spraying thrust aerating and cooling tower, and jet flow cool wind machine

InactiveCN100520266CIncrease temperature dropEasy windingTrickle coolersAir conditioning systemsAir volumeCooling tower

Downspray spray push draft cooling towers and jet coolers. The tower body is equipped with an external rotating spray propulsion and exhaust device that injects hot water under pressure and sprays mist flow. The nozzle sprays downward and the blades draw air downward; The middle and lower part of the tower wall is equipped with wind buckets. There is a multi-layer water spray screen under the spray device, which distributes water and guides the wind to make the water spray evenly, and the cold air passes through the water mist flow for multiple times to fully exchange heat, which greatly improves the heat transfer efficiency. Because the wind and water are in the same direction, the interference of water mist on the wind blades is reduced, the force of the jet flow is increased, and the downward direction of the spray flow ejection wind can also be used, that is, the three airflows of the wind blade mechanical wind, the spray ejection wind and the fan ejection wind are generated. Heat exchange with the spray flow, the air volume is increased, the air-water ratio is above 1.0, which is 29-90% higher than the existing spray cooling tower, and the temperature drop can be greatly improved. The noise of the water flow in the tower is reduced; the top of the tower does not float; the working water pressure drop is 0.08-0.12MPa. Because the outlet air temperature is similar to the outlet water temperature, it can be used as a jet cooler at the same time for cooling and air conditioning in spring, summer and autumn.

Owner:魏仕英

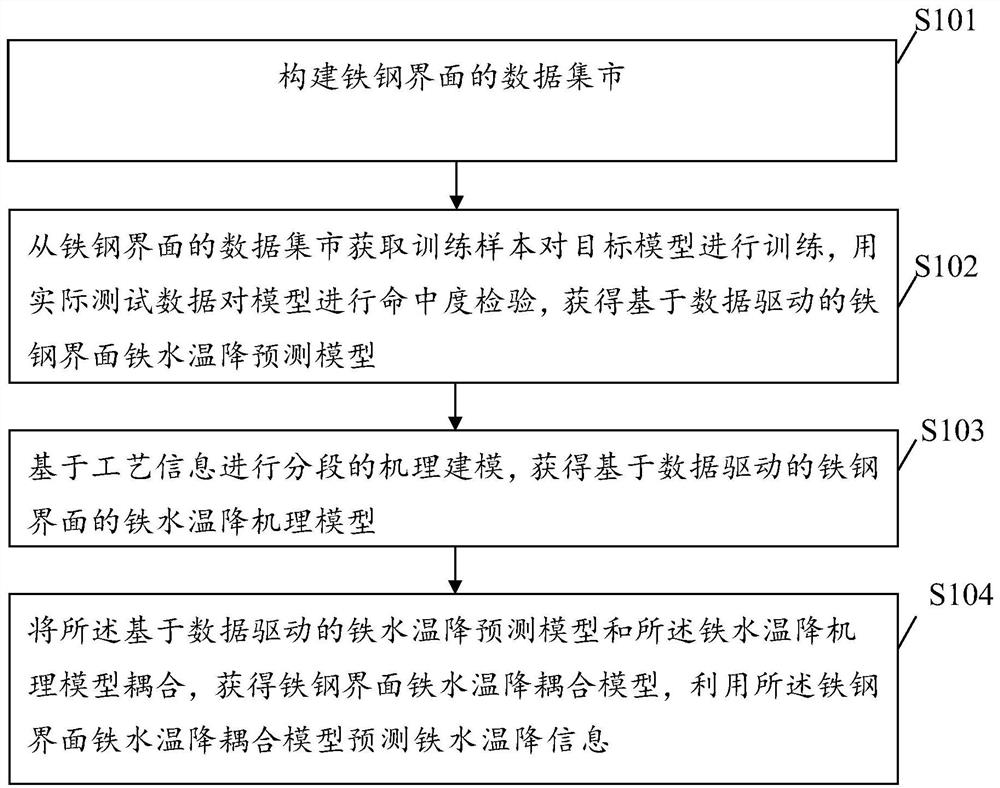

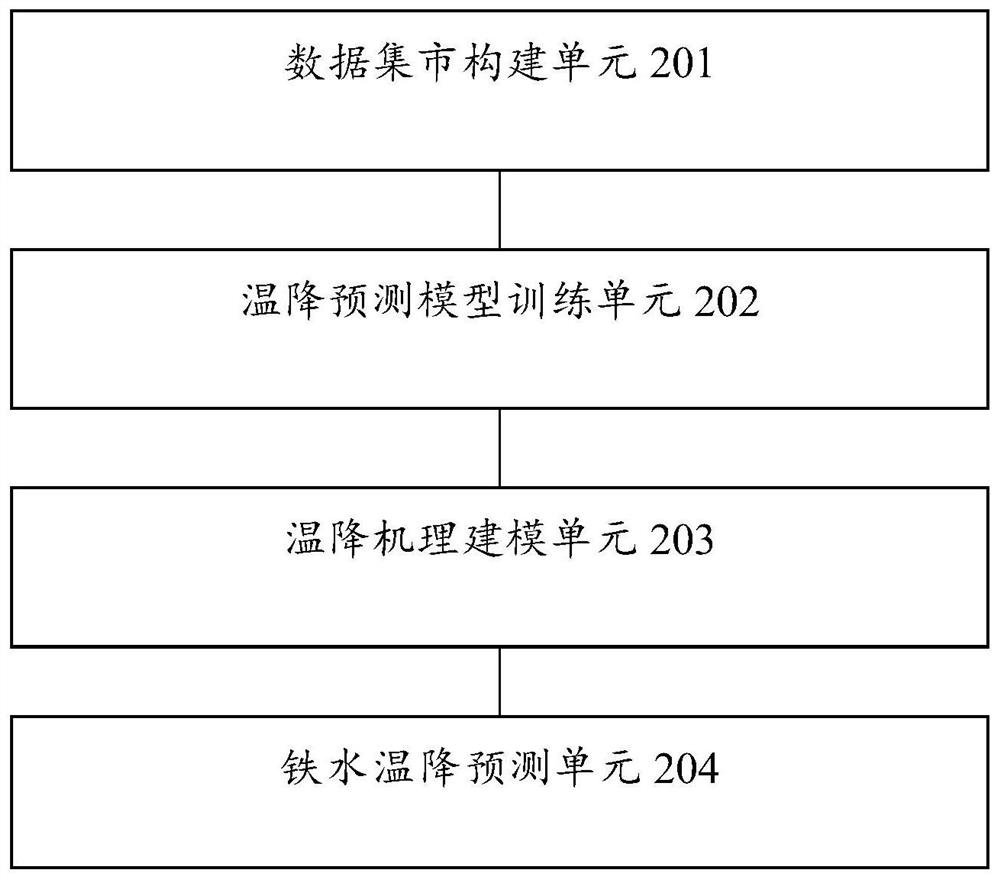

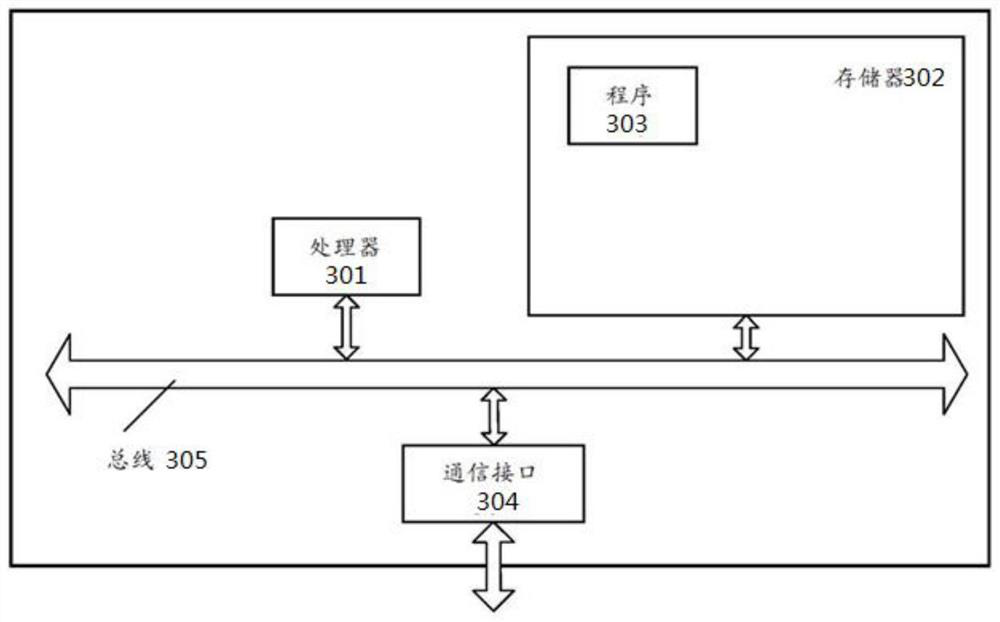

Method, device and terminal equipment for predicting temperature drop of molten iron at iron-steel interface

ActiveCN112434961BIncrease temperature dropEasy to digForecastingDesign optimisation/simulationData setTerminal equipment

The present application discloses a method, device and terminal equipment for predicting the temperature drop of molten iron at the iron-steel interface. The method includes: building a data mart for the iron-steel interface; obtaining training samples from the data mart for the iron-steel interface to train the target model, Obtain the prediction model of molten iron temperature drop at the iron-steel interface; perform segmented mechanism modeling based on process information, and obtain a data-driven iron-steel interface molten iron temperature drop mechanism model; combine the data-driven iron-steel interface molten iron temperature drop prediction model and The coupling model of the molten iron temperature drop mechanism is obtained to obtain the coupled model of the molten iron temperature drop at the iron-steel interface, and the molten iron temperature drop information is predicted using the coupled model of the molten iron temperature drop at the iron-steel interface. Using the method for predicting the temperature drop of molten iron at the iron-steel interface described in this application can accurately predict the temperature change of molten iron in real time online, facilitate subsequent control of the temperature drop of molten iron, provide molten iron with stable composition and temperature, and contribute to the improvement of energy efficiency at the iron-steel interface, It is of great significance to reduce costs and increase efficiency, improve production efficiency and clean production.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Evaporative water chilling unit comprising parallel air coolers, air filter and water filter

InactiveCN101713580BImprove the coefficient of performanceImprove efficiencyEnergy recovery in ventilation and heatingLighting and heating apparatusEvaporative coolerFiltration

The invention discloses an evaporative water chilling unit comprising parallel air coolers, an air filter and a water filter, wherein a primary direct evaporative cooler and a secondary direct evaporative cooler which are connected in parallel are arranged in a shell of the unit, and a primary air cooler and a secondary air cooler which are connected in parallel are also arranged in the shell of the unit; an air filtering and dust removing device is arranged at one side of the primary direct evaporative cooler; an exhaust fan is arranged at one side of the secondary direct evaporative cooler;and a water collecting box and the water filter are respectively arranged at the lower parts of the two direct evaporative coolers. The water chilling unit of the invention adopts the mode of arranging the primary air cooler and the secondary air cooler in parallel and arranging the primary direct evaporative cooler and the secondary direct evaporative cooler in parallel, and simultaneously, the active air filter and the active water filter are arranged for two-stage filtration; the evaporative cooling technology is fully utilized to prepare high-temperature cold water of which the temperature is between wet-bulb temperature and dew-point temperature; and compared with the traditional water chilling unit refrigerated mechanically, the evaporative water chilling unit of the invention is more economic, energy-saving and environment-friendly and has higher coefficient of performance (cop).

Owner:XI'AN POLYTECHNIC UNIVERSITY

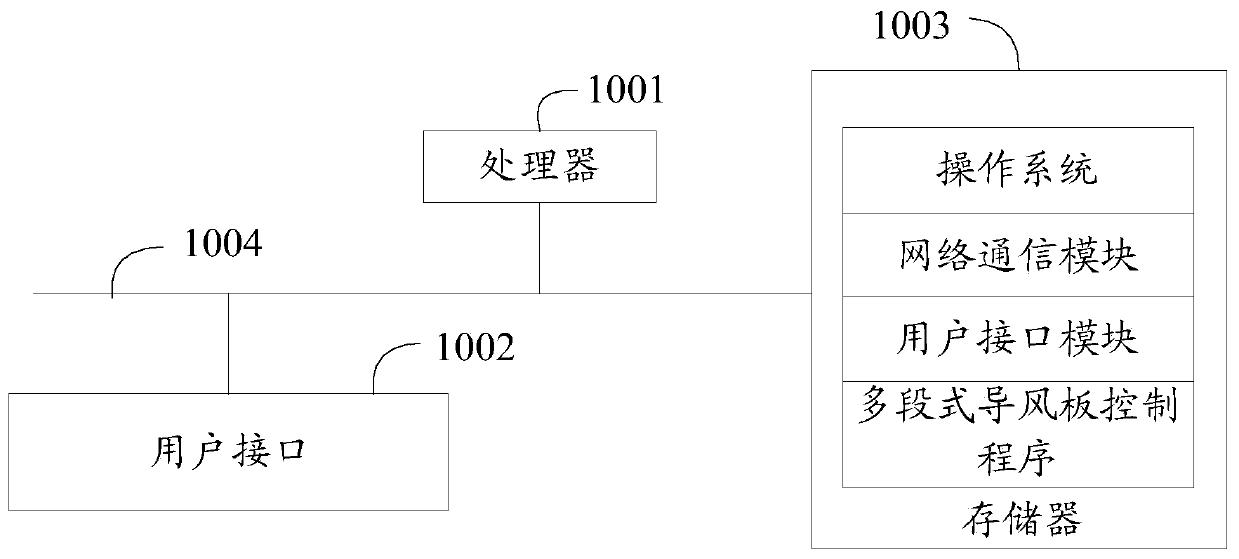

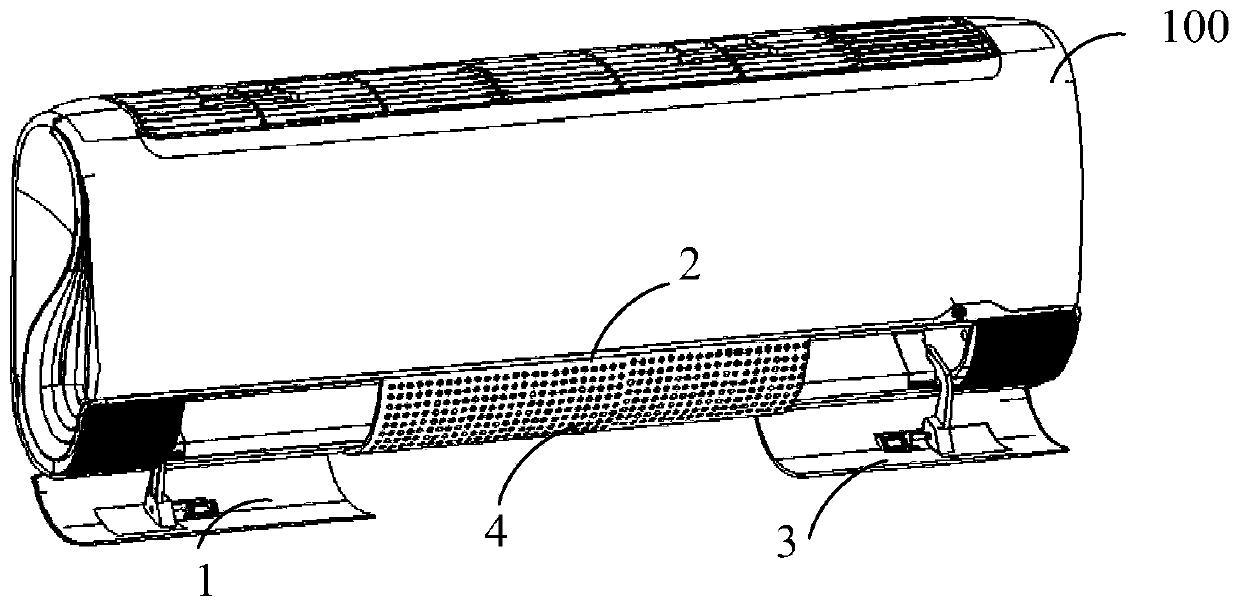

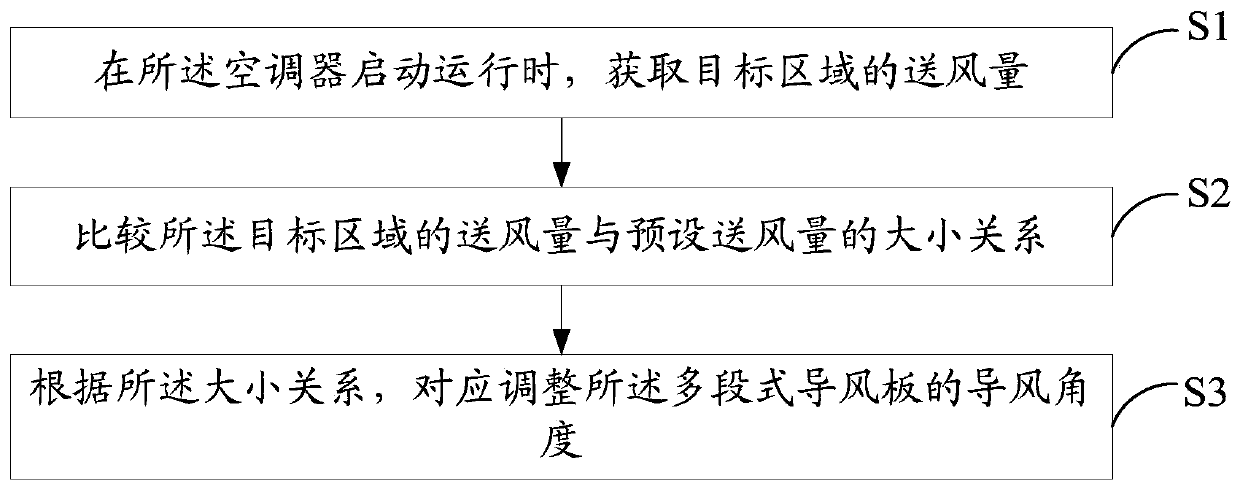

Air conditioner, multi-stage wind deflector control method, and computer-readable storage medium

ActiveCN108397867BFlexible adjustment of air supply volumeFlexible adjustment of air guide angleMechanical apparatusSpace heating and ventilation safety systemsThermodynamicsControl engineering

The invention discloses a method for controlling a multi-stage air deflector of an air conditioner. The method for controlling a multi-stage air deflector of an air conditioner includes the following steps: when the air conditioner starts to operate, obtain the air supply volume of a target area; compare The size relationship between the air supply volume of the target area and the preset air supply volume; according to the size relationship, the wind guide angle of the multi-section air deflector is correspondingly adjusted. The invention also discloses an air conditioner and a computer-readable storage medium. The present invention uses multi-section air deflectors to flexibly adjust the air guide angles of one or more sections of air deflectors according to different requirements, so as to realize the adjustment of air supply volume and further increase the speed of temperature drop or temperature rise.

Owner:GD MIDEA AIR CONDITIONING EQUIP CO LTD +1

A new type of air conditioner dehumidifier

ActiveCN103307677BAchieve dehumidification functionConserve waterLighting and heating apparatusSpace heating and ventilation detailsLiquid storage tankEngineering

A novel air conditioner dehumidification unit adopts the structure that a compressor, a separating tank and a liquid storage tank are respectively connected with three ports of a reversing valve, and the other three ports of the reversing valve are respectively connected with two ports of first plate fin type heat exchangers and one end of a dew point indirect evaporative cooling device; and the other end of the dew point indirect evaporative cooling device is communicated with the liquid storage tank; the separating tank is communicated with the compressor; the first plate fin type heat exchangers are arranged on the function sections of a combined type air-handling unit; a second throttle valve is arranged on a connecting pipeline of the liquid storage tank and the reversing valve; a first throttle valve is arranged on the connecting pipeline of the dew point indirect evaporative cooling device and the liquid storage tank; in a refrigeration working condition, the second throttle valve works, and in the heating working condition, the first throttle valve works; and in field where dehumidification is required, second plate fin type heat exchangers are additionally arranged on the function sections of the combined type air-handling unit. According to the unit provided by the invention, the cold / hot water circulating system is saved, three working conditions of refrigeration, heating and dehumidification are realized, the heat exchange efficiency is high, and the remarkable effects of energy conservation and emission reduction can be achieved.

Owner:无锡金龙石化冶金设备制造有限公司 +1

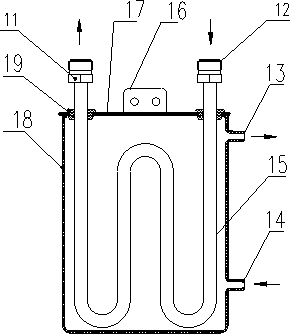

Water cooling device for vehicle air conditioner

InactiveCN103743015AImprove cooling speedIncrease temperature dropMechanical apparatusCompression machines with non-reversible cycleWater savingLiquid storage tank

The invention provides a water cooling device for a vehicle air conditioner. The device comprises a heat exchange unit, a compressor, an evaporator, an expansion valve, a drying bottle and a condenser. The heat exchange device comprises a heat exchange tube and a water cooling liquid storage tank. Two tube ports of the heat exchange tube are arranged at the top of the water cooling liquid storage tank and are a coolant outlet and a coolant inlet. A condensate water outlet and a condensate water inlet are formed on the side of the water cooling liquid storage tank. The coolant inlet is connected with the compressor, and the coolant outlet is connected with the condenser. The condensate water inlet is connected with the evaporator, and the condensate water outlet is connected with a water saving tank. The evaporator is connected with the drying bottle, the expansion valve is arranged on a connection tube between the evaporator and the drying bottle, and the drying bottle is connected with the condenser. According to the water cooling device, by the usage of the heat exchange unit, the refrigeration speed of the whole air conditioner is improved, the vehicle indoor temperature reduction is accelerated, and the refrigeration capacity is improved by about 20% to 30%.

Owner:柳州力通汽车科技有限公司

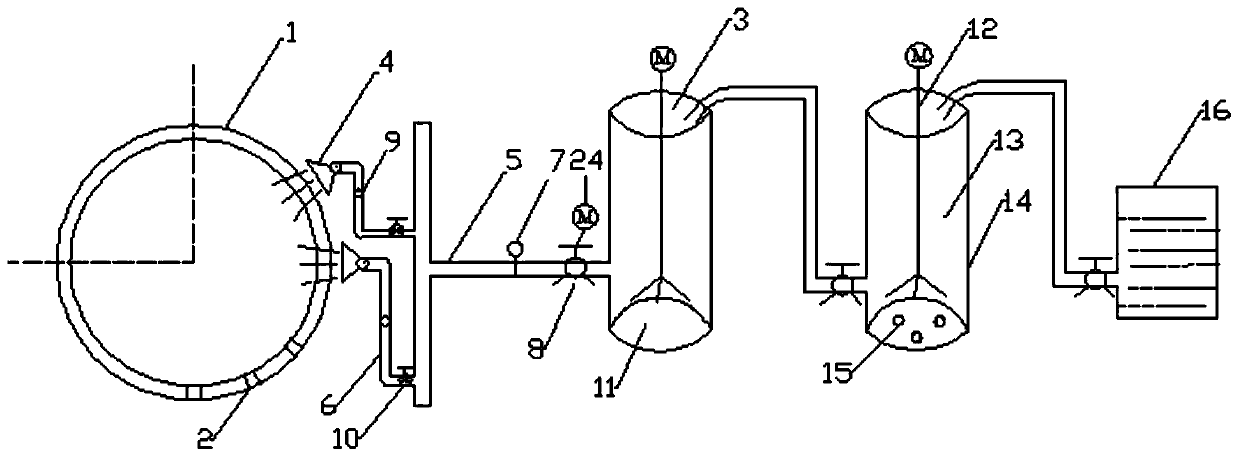

Flaking machine with flame retardant sprinkling structure and flame retardant sprinkling method

PendingCN109746985AImprove flame retardant performanceIncrease coverageFlat surfacing machinesWood impregnation detailsFire retardantKnife blades

The invention discloses a flaking machine with a flame retardant sprinkling structure and a flaking method. The flaking machine comprises a knife ring, knife blades and a sprinkling structure, whereinthe knife blades are distributed on the knife ring; the sprinkling structure comprises a flame retardant storing tank, one or two or more than two spray heads and a transporting pipeline; the spray heads is connected with the flame retardant storing tank through the transporting pipeline; and the spray heads are distributed on the periphery of the knife ring. When the flaking machine disclosed bythe invention is used for flaking, during flaking, a flame retardant is sprinkled at the same time; and during flaking, various flame retardant solutions are sprinkled, so that beyond all expectation, an excellent coverage rate of the flame retardants can be obtained, and the temperature lowering range of the knife ring and the knife blades is further increased.

Owner:湖北宝源木业有限公司

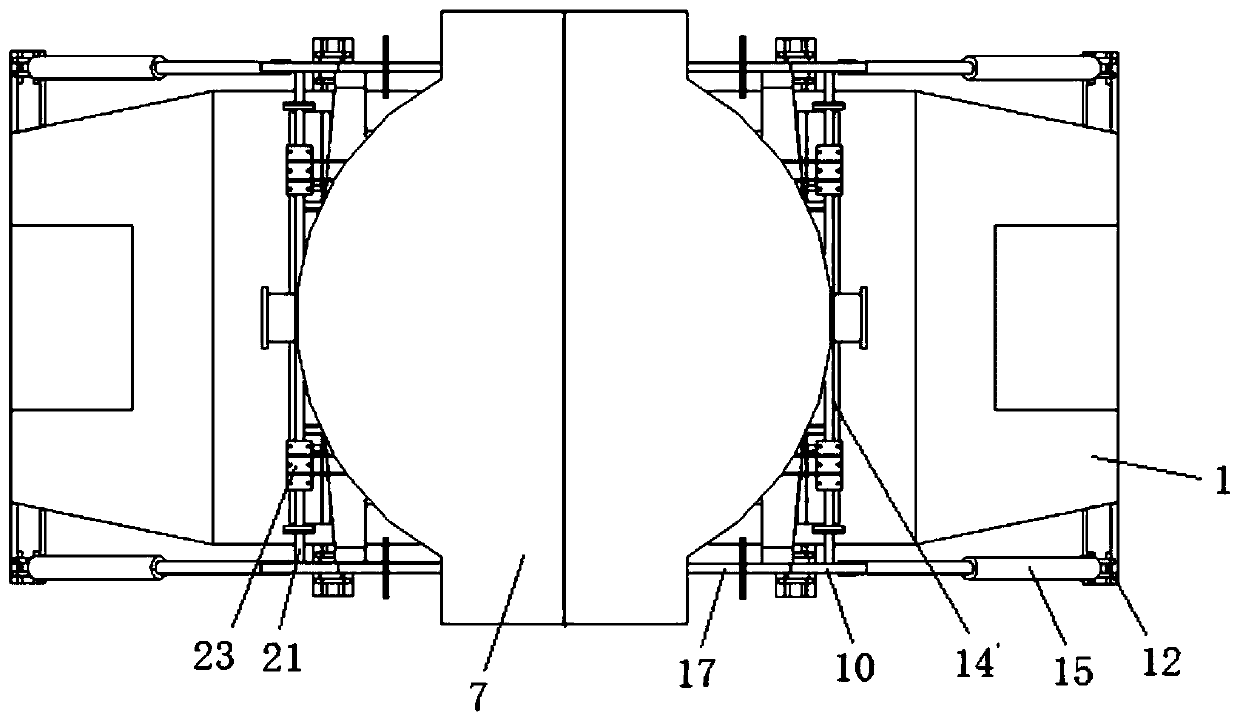

Heat preservation protective device for molten iron tank of molten iron vehicle

PendingCN110434321AIncrease temperature dropReduce splashMelt-holding vesselsSteelmakingHydraulic cylinder

The invention relates to a heat preservation protective device for a molten iron tank of a molten iron vehicle, and belongs to the technical field of iron and steel enterprise molten iron vehicle devices. The device is used for preserving the heat of transported molten iron. According to the technical scheme, a protective cover is composed of two relative semicircular cover bodies, the two semicircular cover bodies are in butt joint and are matched with the top surface and the outer periphery of an opening in the upper end of a molten iron tank, the upper ends of two supporting frames are connected with the two semicircular cover bodies of the protective cover correspondingly, the lower ends of the two supporting frames are connected to the front end and the rear end of the molten iron tank of a molten iron vehicle through vehicle body hinging seats, two hydraulic cylinders are arranged at the front end and the rear end of the molten iron vehicle, the lower ends of the hydraulic cylinders are connected with the vehicle body, the front ends of hydraulic push rods of the hydraulic cylinders are hinged to the middles of the supporting frames, and the hydraulic cylinders are connectedwith hydraulic pumps. The device has the beneficial effects that the excessive temperature drop of the molten iron in the molten iron tank of the molten iron vehicle can be avoided, the smooth proceeding of the subsequent steelmaking process is guaranteed, the production efficiency is improved, the molten iron in the molten iron tank can be protected from being influenced by external factors, andthe safety of the device and personnel is guaranteed.

Owner:宣化钢铁集团有限责任公司

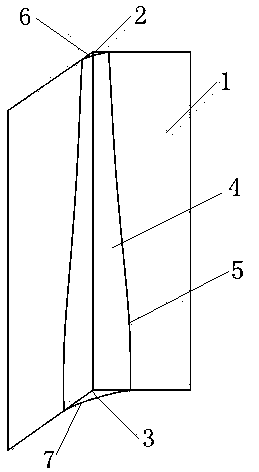

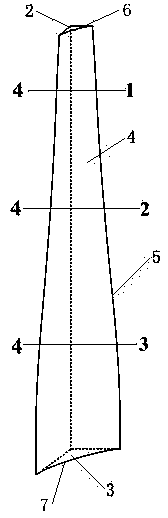

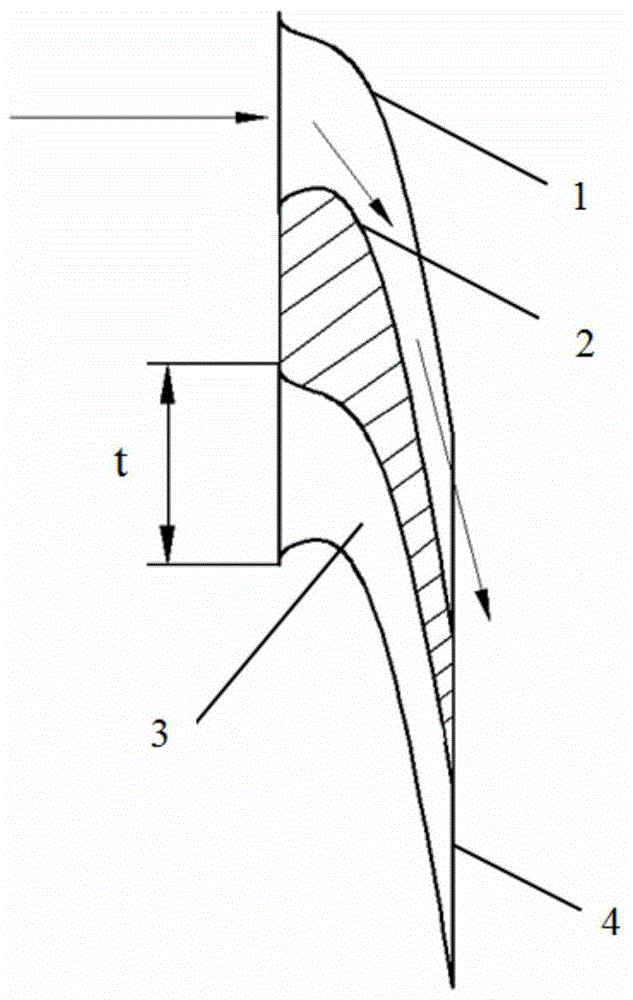

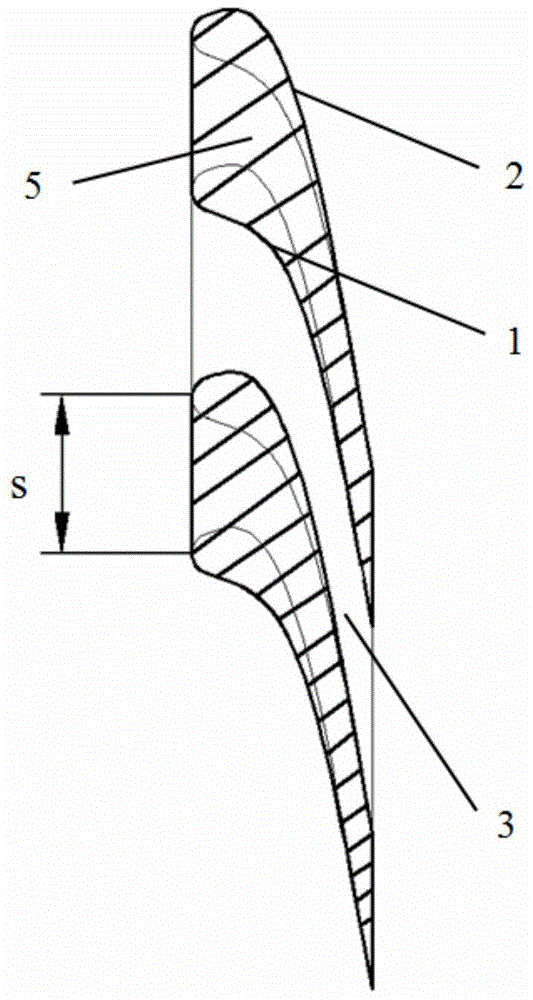

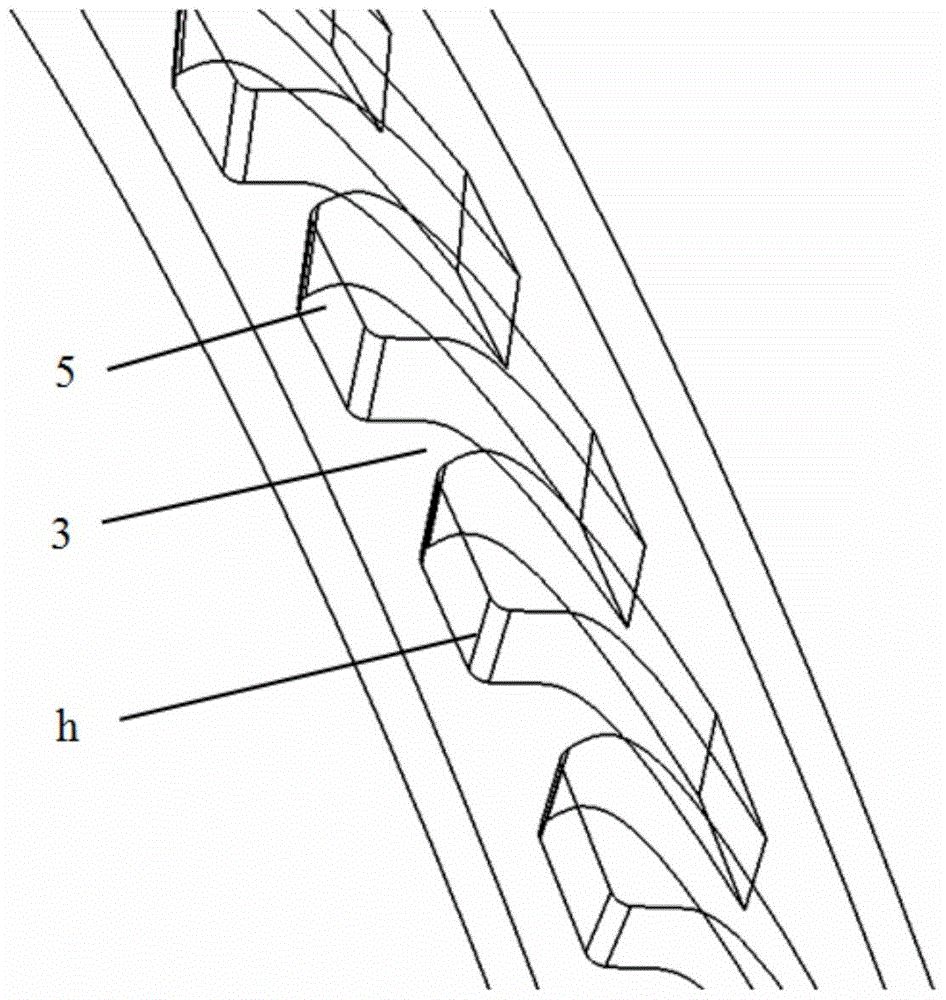

A leaf-hole pre-swirl nozzle for a pre-swirl cooling system

InactiveCN105114186BImprove flow coefficientImprove efficiencyTurbine/propulsion engine coolingAviationEngineering

The invention discloses a blade hole type prewhirl nozzle for a prewhirl cooling system, and belongs to the field of application of aero-engine prewhirl cooling systems. The blade hole type prewhirl nozzle is characterized in that a blade pressure face and a blade suction face are adopted for forming inclined hole runners deflecting in the circumferential direction of a nozzle ring at equal intervals, deflecting molded faces of the nozzle runners are in a gradually-contracted shape, a minimum laryngeal area is achieved at an outlet of the prewhirl nozzle, the accelerating performance and the deflecting performance of the prewhirl nozzle are effectively guaranteed, and the flowing loss of a main flow is small. Blade type solid blocks are distributed between adjacent runners of the prewhirl nozzle, under the condition that the laryngeal area of the nozzle is definite, the ratio of the blade height to the pitch of the prewhirl nozzle can be flexibly adjusted by additionally arranging the blade type solid blocks, and the long and narrow performance of the sections of the runners is effectively improved, so that the secondary flow loss of the end walls in the runners is reduced, the flow coefficient and the prewhirl efficiency of the prewhirl nozzle are improved, and the system temperature drop effect is further improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

A kind of production method of ultra-low phosphorus hydrogen-prone steel

ActiveCN107868900BIncrease temperature dropIncrease processing costManufacturing convertersHydrogenChemical composition

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

A progressive arc chamfering crystallizer with enhanced water cooling structure and its design method

The invention belongs to the field of billet continuous casting production, and specifically relates to a progressive arc-shaped chamfered crystallizer with an enhanced water-cooling structure and a design method. The mold of the present invention has four upper opening chamfers and four lower opening chamfers. Along the height direction of the inner wall of the crystallizer, from the upper opening chamfer to the lower opening chamfer, the chamfering angles follow the heat shrinkage rules of the corners of the casting slab. Gradually increases, the chamfer surface formed between the upper chamfer and the lower chamfer is a gradient arc surface. The transition arc length of the gradient arc surface boundary increases according to the air gap growth law. The upper chamfer is located on the chamfer surface. The hypotenuse on the top is a straight line or an arc, and the hypotenuse on the chamfer surface of the lower chamfer is also a straight line or an arc. The mold of the present invention effectively suppresses air gaps through a unique arc-shaped chamfer structure, improves heat transfer at the corners of the billet, and uniformly grows the billet shell. By enhancing the water-cooling structure in the chamfer area, the cooling speed at the corners of the mold is significantly increased, and the mold becomes finer. The chamfered contact surface grains are reduced to suppress the occurrence of corner defects.

Owner:NORTHEASTERN UNIV LIAONING

Oriented strand board production system and oriented strand board production method provided with flame retardant spraying structure

ActiveCN109732737BFully absorbedEvenly distributedWood working apparatusDomestic articlesProcess engineeringOriented strand board

The invention discloses an oriented particle board production system and a production method provided with a flame retardant spraying structure. The production system includes: flaking device, wet flaking conveying device, wet flaking silo, drying device, dry flaking conveying device 1, screening device, dry flaking silo, dry flaking conveying device 2, glue mixing device, paving device, hot pressing device and flame retardant spraying structure; the flame retardant spraying structure is connected with the flaking device, dry flaking conveying device 1 and / or dry flaking conveying device 2, glue mixing device, The paving device is connected. The present invention adopts multi-process spraying, the shavings absorb fully, and the flame retardant is evenly distributed. By spraying various flame retardant solutions while shaving, it can unexpectedly obtain excellent coverage of the flame retardant and further improve the flame retardant. Cooling of rings and blades. The flame-retardant oriented strand board obtained by the treatment has excellent flame-retardant performance; the physical properties are equivalent to those of the oriented strand board produced and pressed without adding a flame retardant.

Owner:湖北宝源木业有限公司

Three-stage evaporative cooling - variable channel air supply system for textile mills

InactiveCN105650784BReduce cooling energy consumptionEnergy saving highlightsLighting and heating apparatusSpace heating and ventilation detailsTextile millAir volume

Owner:XI'AN POLYTECHNIC UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com