Method and system for improving water cooling quality of TMCP steel plate

A steel plate, water cooling technology, applied in workpiece cooling device, workpiece surface treatment equipment, metal rolling, etc., can solve problems such as poor water cooling quality of steel plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In this embodiment, a method for improving the water-cooling quality of TMCP steel plates is provided. The method of the present invention improves the original TMCP production line, and a pre-leveler is installed at the entrance of the water-cooling equipment in the original TMCP production line; There are no restrictions on some straightening equipment, as long as they can meet the straightening needs of wide and thick plates.

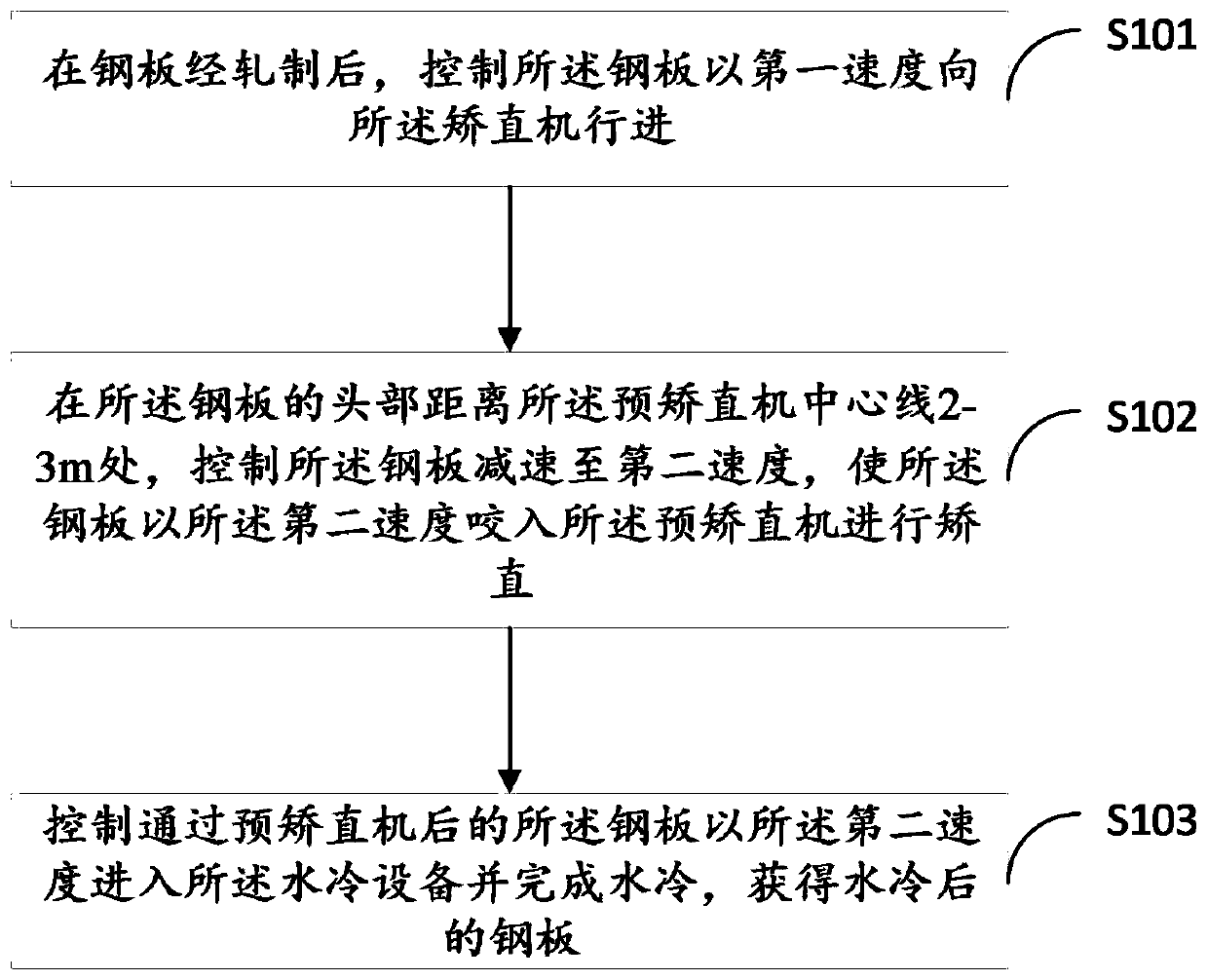

[0040] see figure 1 , the method includes:

[0041] S101. After the steel plate is rolled, control the steel plate to advance towards the straightening machine at a first speed;

[0042] S102. When the head of the steel plate is 2-3m away from the center line of the pre-leveler, control the steel plate to decelerate to a second speed, so that the steel plate bites into the pre-leveler at the second speed machine for straightening;

[0043] S103. Control the steel plate passing through the pre-leveler to enter the water cooling equipment at ...

Embodiment 2

[0061] In this embodiment, a system for improving the water-cooling quality of TMCP steel plates is used in a TMCP production line, and a pre-leveler is installed at the entrance of the water-cooling equipment in the TMCP production line;

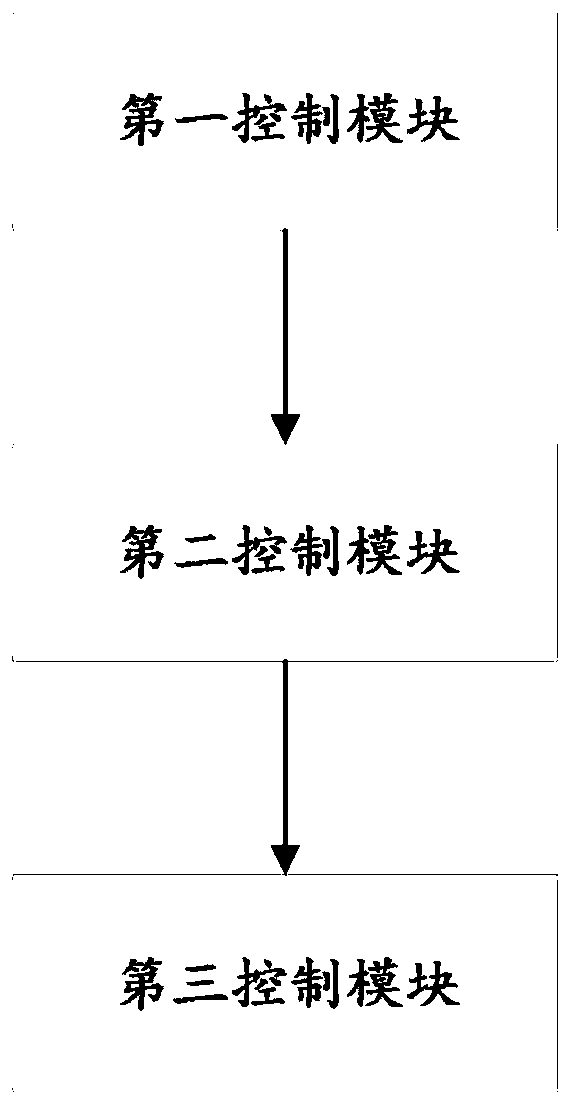

[0062] see figure 2 , the system includes:

[0063] The first control module is used to control the steel plate to travel to the straightening machine at a first speed after the steel plate is rolled;

[0064] The second control module is used to control the deceleration of the steel plate to a second speed when the head of the steel plate is 2-3m away from the center line of the pre-leveler, so that the steel plate bites at the second speed The pre-straightener performs straightening;

[0065] The third control module is used to control the steel plate passing through the pre-leveler to enter the water cooling equipment at the second speed and complete water cooling to obtain a water cooled steel plate. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com