Control device and control method for refining ladle slag emulsification

A technology of a control device and a control method, which is applied in the direction of manufacturing tools, casting melt containers, casting equipment, etc., can solve the problems of reducing plasticity, toughness and fatigue limit, corrosion of furnace lining refractory materials, and brittle fracture of steel. Stabilize the emulsification phenomenon, improve the temperature drop of molten steel, and improve the effect of cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

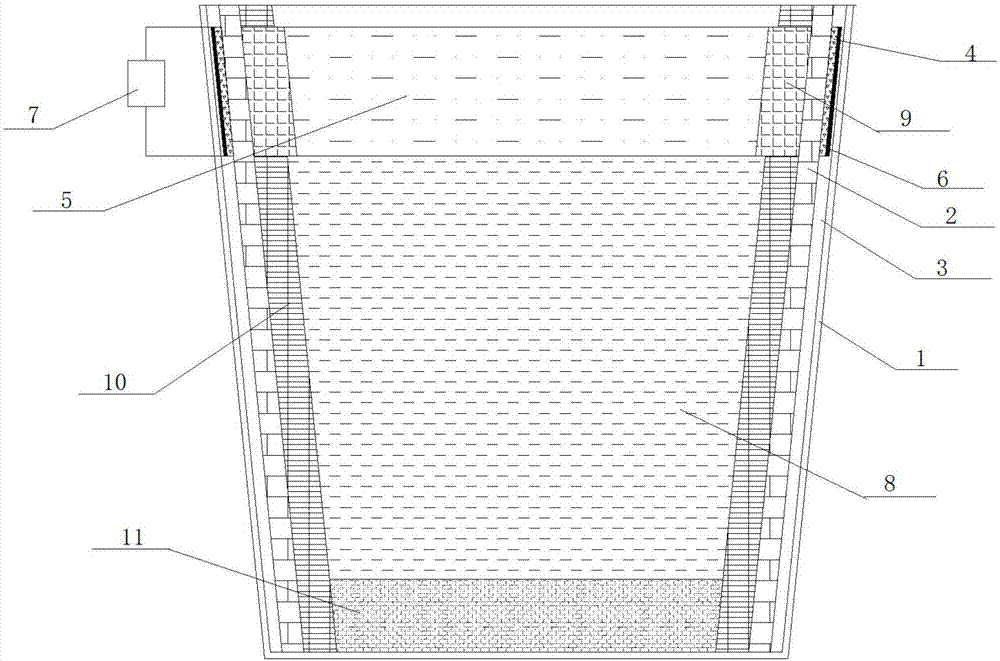

Embodiment 1

[0020] A control device for slag emulsification of a refining ladle 1, including a furnace body, the wall of the furnace body includes a refractory layer, a permanent layer 2 of the furnace body and an insulation layer 3 arranged in sequence from the inside to the outside, and a brick layer is arranged at the bottom of the furnace body 11. The insulation layer 3 and the block layer 11 are provided with cladding steel covering the entire furnace body; the refractory layer includes a molten steel refractory layer 10 located at the lower part of the furnace body and a slag line refractory layer 9 located at the upper part of the furnace body, and the upper part of the thermal insulation layer 3 A coil 4 is provided at the same position as the slag line refractory layer 9 , and the two ends of the coil 4 are respectively connected to two poles of a DC power supply 7 . The steel cladding on the bottom surface of the furnace body is provided with an air inlet for inputting gas to the...

Embodiment 2

[0026] In this embodiment, an inorganic insulated electromagnetic wire with a diameter of 1 to 2 mm is evenly wound between the permanent layer 2 of the furnace body of the ladle 1 and the insulation layer 3 to form a coil 4 surrounding the furnace body with 3000 to 5500 turns, covering the entire slag layer 5, Apply a layer of 1-2mm SiC-Si-Al cement evenly on the outer side of the coil 4, connect the coil 4 to the DC power supply 7 in two stages, and other settings are the same as in Example 1; 1-3 minutes after the bottom blowing of argon gas in the refining ladle 1 starts , turn on the DC power supply 7, adjust the voltage to 130-160V, and the current to 11-15A, and the slag surface is in a dynamic and stable state.

Embodiment 3

[0028] In this embodiment, an inorganic insulated electromagnetic wire with a diameter of 2 to 3 mm is evenly wound between the permanent layer 2 of the furnace body of the ladle 1 and the insulation layer 3 to form a coil 4 surrounding the furnace body with 500 to 3000 turns, covering the entire slag layer 5, Apply a layer of 1-2mm SiC-Si-Al cement evenly on the outer side of the coil 4, connect the coil 4 to the DC power supply 7 in two stages, and other settings are the same as in Example 1; 1-3 minutes after the bottom blowing of argon gas in the refining ladle 1 starts , turn on the DC power supply 7, adjust the voltage to 100-130V, and the current to 7-11A, and the slag surface is in a dynamic and stable state.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com