Method for rolling interstitial free steel ferrite on traditional hot rolling mills

A technology of interstitial atom-free steel and ferrite, which is applied in the field of IF steel rolling, can solve the problem that the finishing rolling is easy to fall into the two-phase region, and achieve the effect of improving the structure and deep drawing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

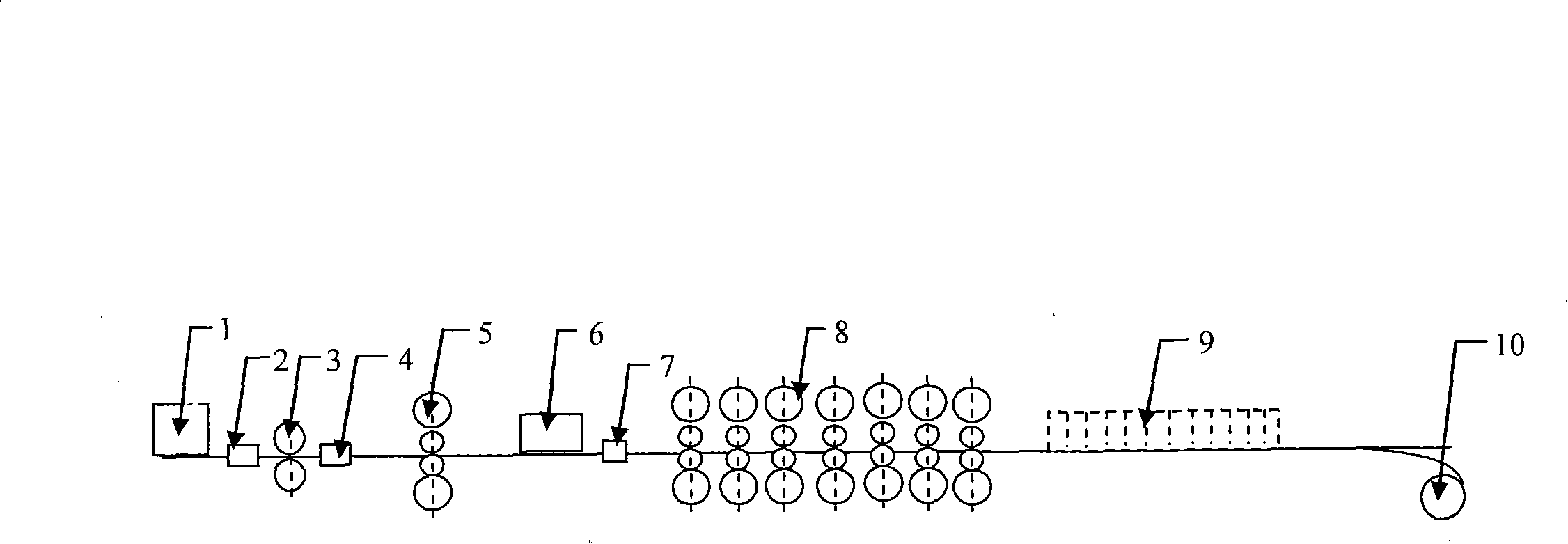

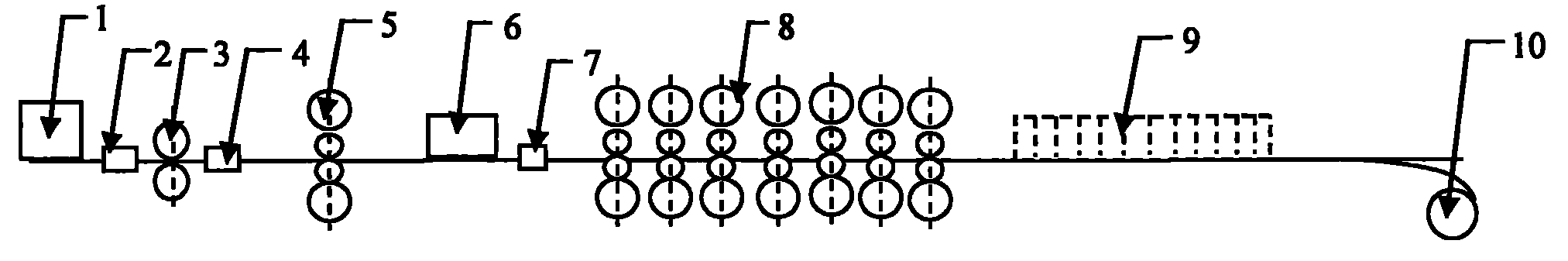

Method used

Image

Examples

Embodiment 1

[0015] Example 1: The hot rolling process is as follows: slab heating temperature 1148°C, finish rolling inlet temperature 862°C, finish rolling temperature 810°C, coiling temperature 704°C, middle slab thickness 38mm, hot rolled sheet thickness specification 2.05mm. The chemical composition of molten steel is: C: 0.0025%; Si: 0.016%; Mn: 0.16%; P: 0.012%; S: 0.0060%; Ti: 0.048%.

Embodiment 2

[0016] Example 2: The hot rolling process is as follows: slab heating temperature 1145°C, finish rolling inlet temperature 850°C, finish rolling temperature 800°C, coiling temperature 702°C, middle slab thickness 38mm, hot rolled plate thickness specification 2.1mm. The chemical composition of molten steel is: C: 0.0022%; Si: 0.015%; Mn: 0.17%; P: 0.013%; S: 0.0056%; Ti: 0.052%.

Embodiment 3

[0017] Example 3: The hot rolling process is: slab heating temperature 1135°C, finish rolling entrance temperature 860°C, finish rolling temperature +815°C, coiling temperature 692°C, middle slab thickness 38mm, hot rolled plate thickness specification 1.8mm . The chemical composition of molten steel is: C: 0.0025%; Si: 0.018%; Mn: 0.15%; P: 0.015%; S: 0.0062%; Ti: 0.044%.

[0018] The performance of the hot-rolled coil in embodiment 1-3 is shown in the table below

[0019]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com