Flaking machine with flame retardant sprinkling structure and flame retardant sprinkling method

A flame retardant and flaking machine technology, which is applied in the direction of manufacturing flat surface processing machines, wood processing appliances, impregnated wood, etc., can solve the problems of flame retardant performance that cannot meet safety requirements, high process complexity, and high cost, etc. problems, to achieve good flame retardant coverage, simple and easy process, and excellent adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

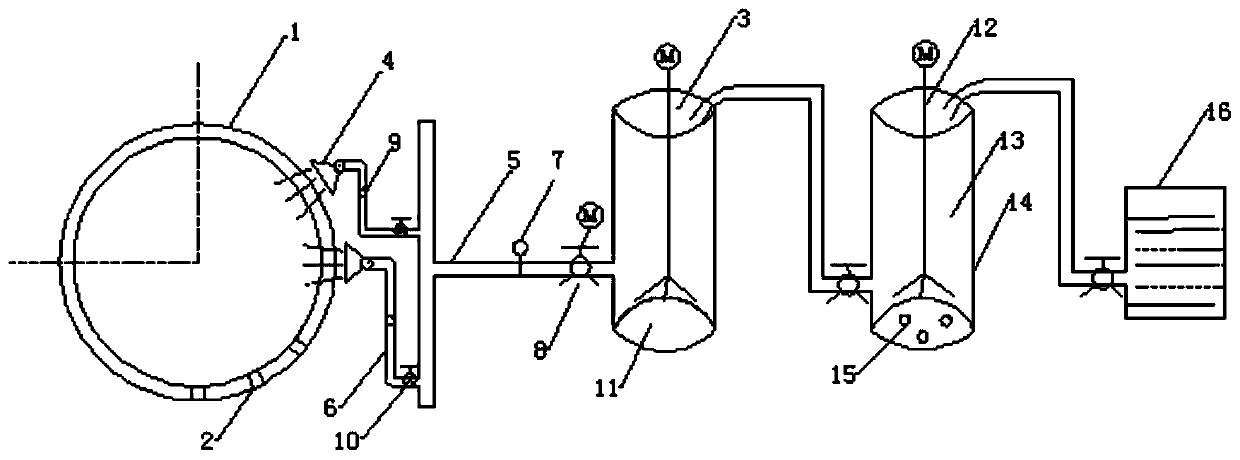

[0057] like figure 1 Shown is provided with the flaking machine of flame retardant spraying structure, and this flaking machine comprises: knife ring 1 and the blade 2 that is evenly distributed on the knife ring 1, the quantity of blade 2 is 48 ( figure 1 Three blades are drawn as an example, and the remaining 45 blades that are not drawn are evenly arranged on the knife ring 1);

[0058] The spraying structure includes: a flame retardant storage tank 3, a pressure nozzle 4 and a flame retardant delivery pipeline, and the pressure nozzle 4 is connected to the flame retardant storage tank 3 through the flame retardant delivery pipeline;

[0059] The injection angle of the pressure nozzle 4 is perpendicular to the blade of the blade 2, so that the angle between the nozzle and the blade is 90°. The number of pressure nozzles 4 is 10, and the pressure nozzles 4 are evenly distributed along the outer circumference of the knife ring 1, and the distance between the pressure nozzles...

Embodiment 2-21

[0067] Adopt the device that embodiment 1 provides, along with the rotation of planer knife ring, blade is planed to wood cutting (planing specification: width 5-40mm, thickness 0.4-0.8mm, length 100-180mm), at the same time, The flame retardant solution is evenly sprayed onto the planer along the direction perpendicular to the blade edge to obtain a flame retardant planer.

[0068] The spraying range of the flame retardant solution can cover all planks.

[0069] The temperature of the flame retardant solution is around 25±5°C;

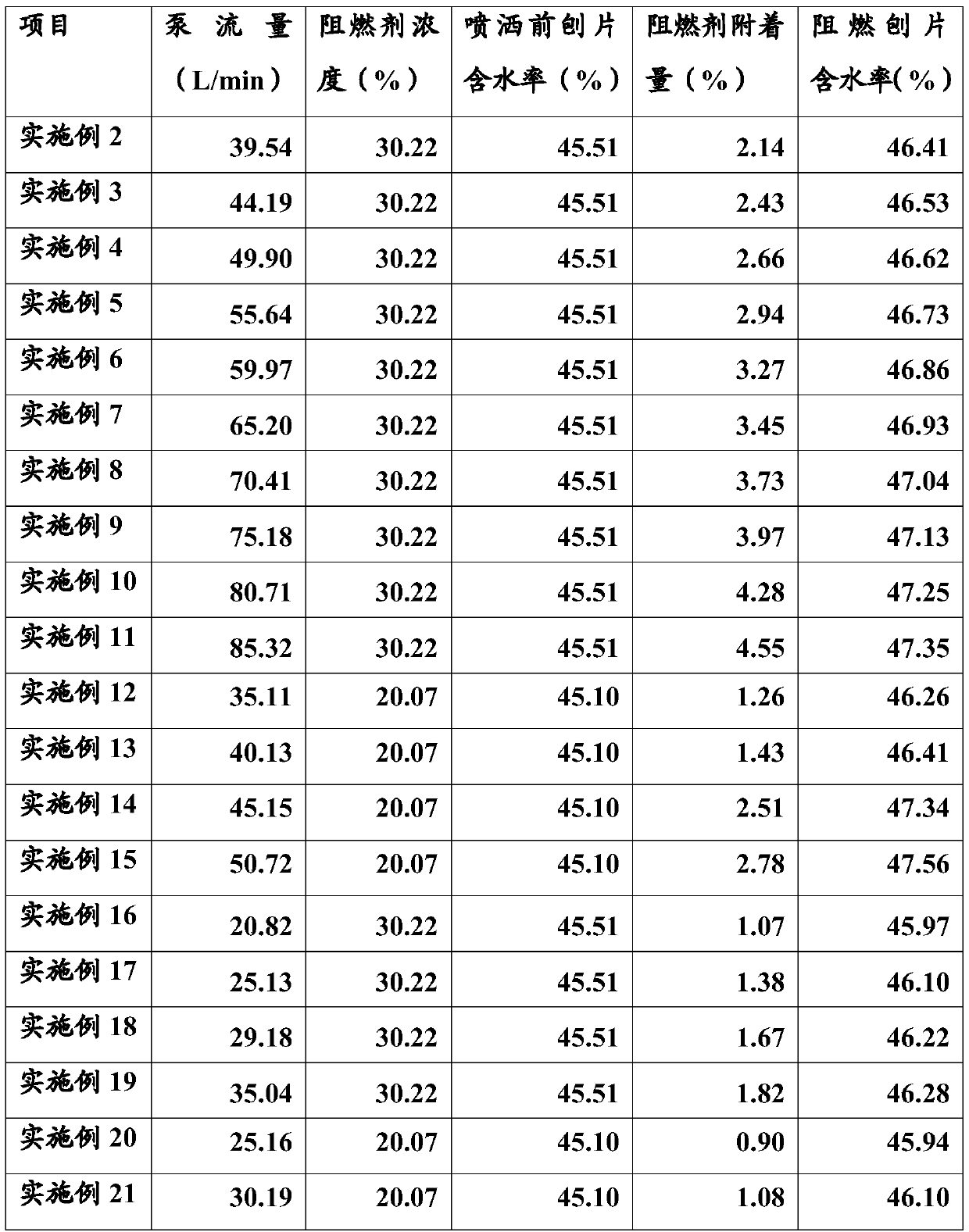

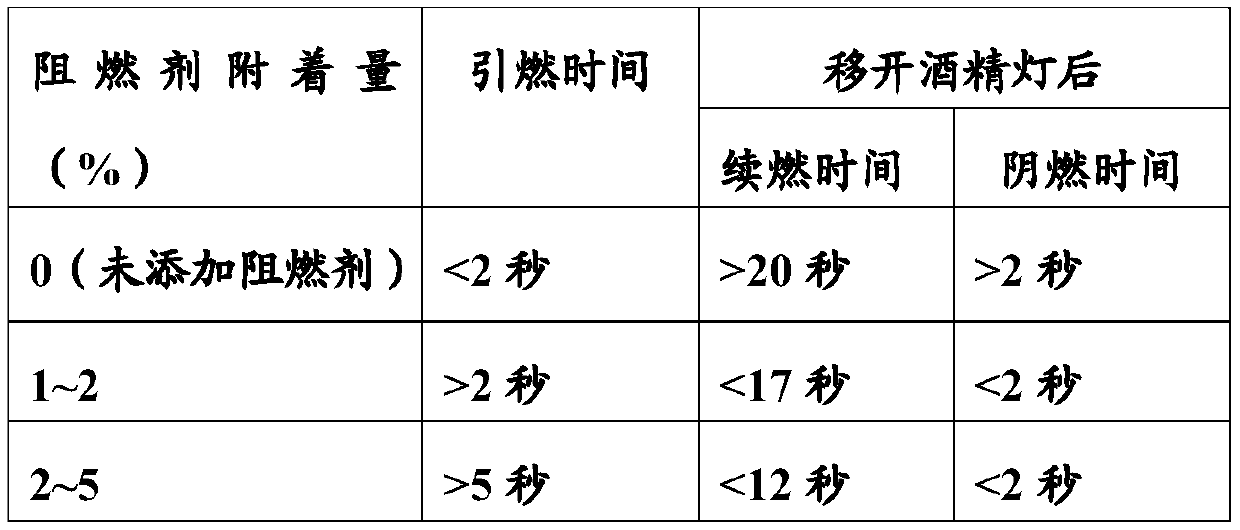

[0070] The concentration of the flame retardant in the flame retardant solution, the adhesion amount of the flame retardant, the spraying amount (indicated by the pump flow rate), and the moisture content of the flakes before and after spraying the flame retardant are shown in Table 1.

[0071] Table 1.

[0072]

[0073] Note: When the pump flow rate reaches the maximum value in the table, there is an obvious liquid outflow phenomenon inside the ...

Embodiment 22

[0107] Example 22 Knife ring temperature monitoring

[0108] After shaving for 10 minutes in Example 2, the temperature of the knife ring was monitored by an infrared temperature detector immediately after the knife ring exited. Each batch of wood needs 4 knives, takes about 1 minute, and monitors 40 batches.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com