Evaporative water chilling unit comprising parallel air coolers, air filter and water filter

A technology for air coolers and chillers, which is used in energy recovery systems for ventilation and heating, shielding with air flow, space heating and ventilation, etc. Time control, preparation of cold water condensation, etc., to achieve the effect of high performance coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

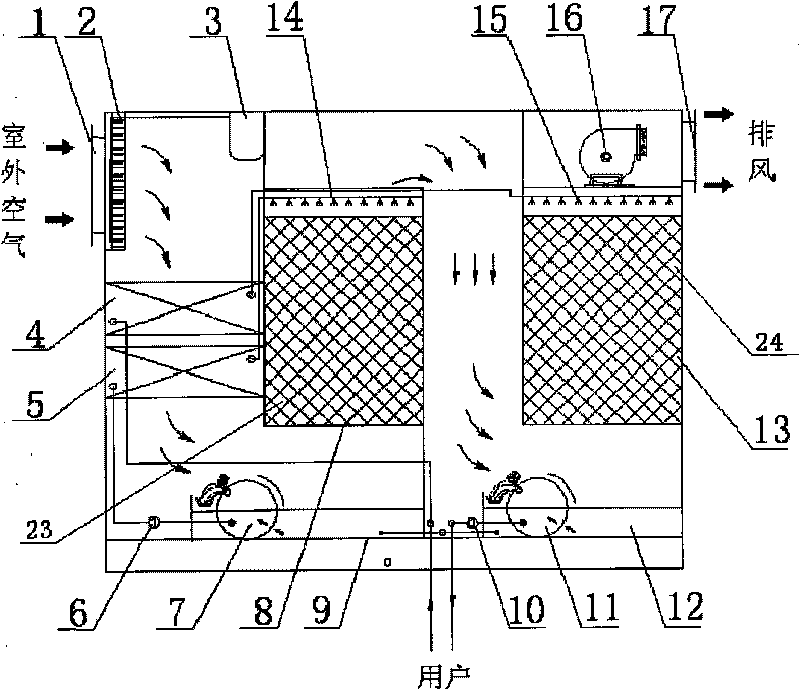

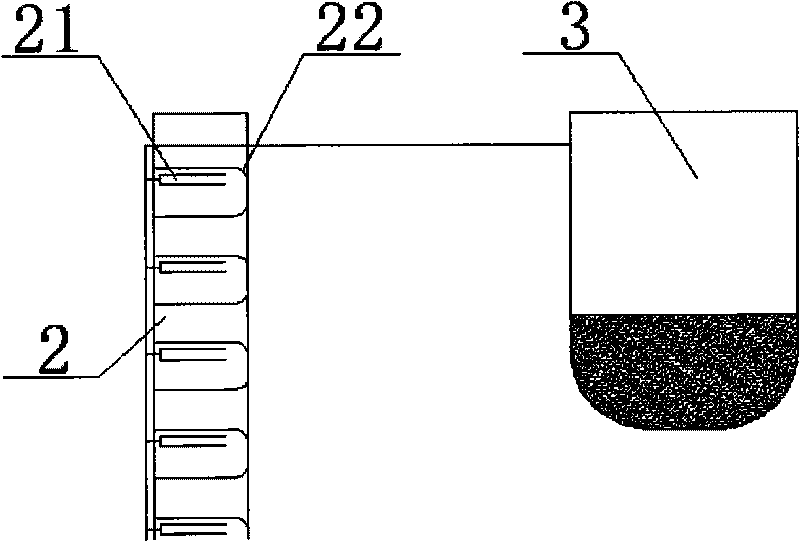

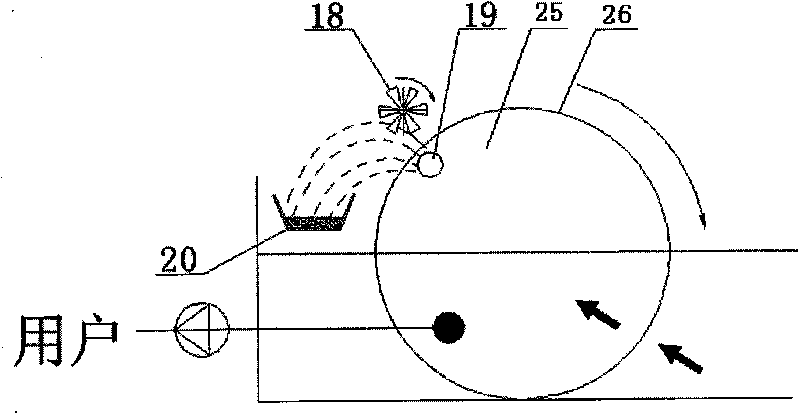

[0022] The evaporative water chiller of the present invention takes the evaporative cooling technology of the air cooler and the direct evaporative cooler as the core, adopts two-stage parallel air coolers to perform equal humidity cooling on the air, and adopts the two-stage parallel direct evaporative cooler to utilize air and The heat and moisture exchange of water takes away heat through the air to produce high-temperature cold water with a water temperature between the wet bulb temperature and the dry bulb temperature. The unit sets the air filter, two-stage parallel air cooler, two-stage parallel direct evaporative cooler, exhaust fan, air filter and water filter into an evaporative cold water combination of air cooler parallel connection, air filter and water filter unit.

[0023] Such as figure 1 As shown, in the evaporative chiller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com