Heat preservation protective device for molten iron tank of molten iron vehicle

A protection device, a technology for a molten iron truck, which is applied in the directions of casting molten material containers, metal processing equipment, casting equipment, etc., can solve the problems of threatening the molten iron truck, the safety of personnel and facilities along the way, affecting the production of steel, splashing molten iron, etc., and achieves remarkable results. Economic and social benefits, improvement of molten iron temperature drop, and effect of improving smelting production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

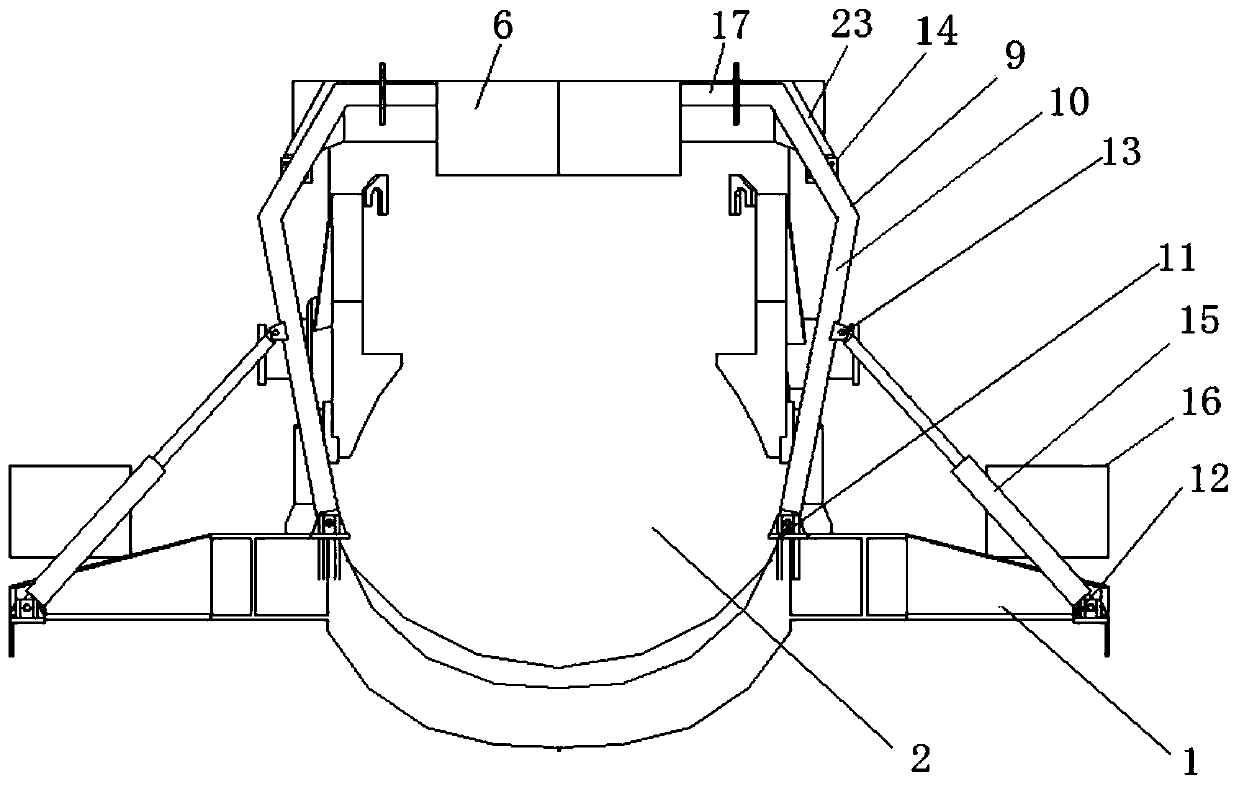

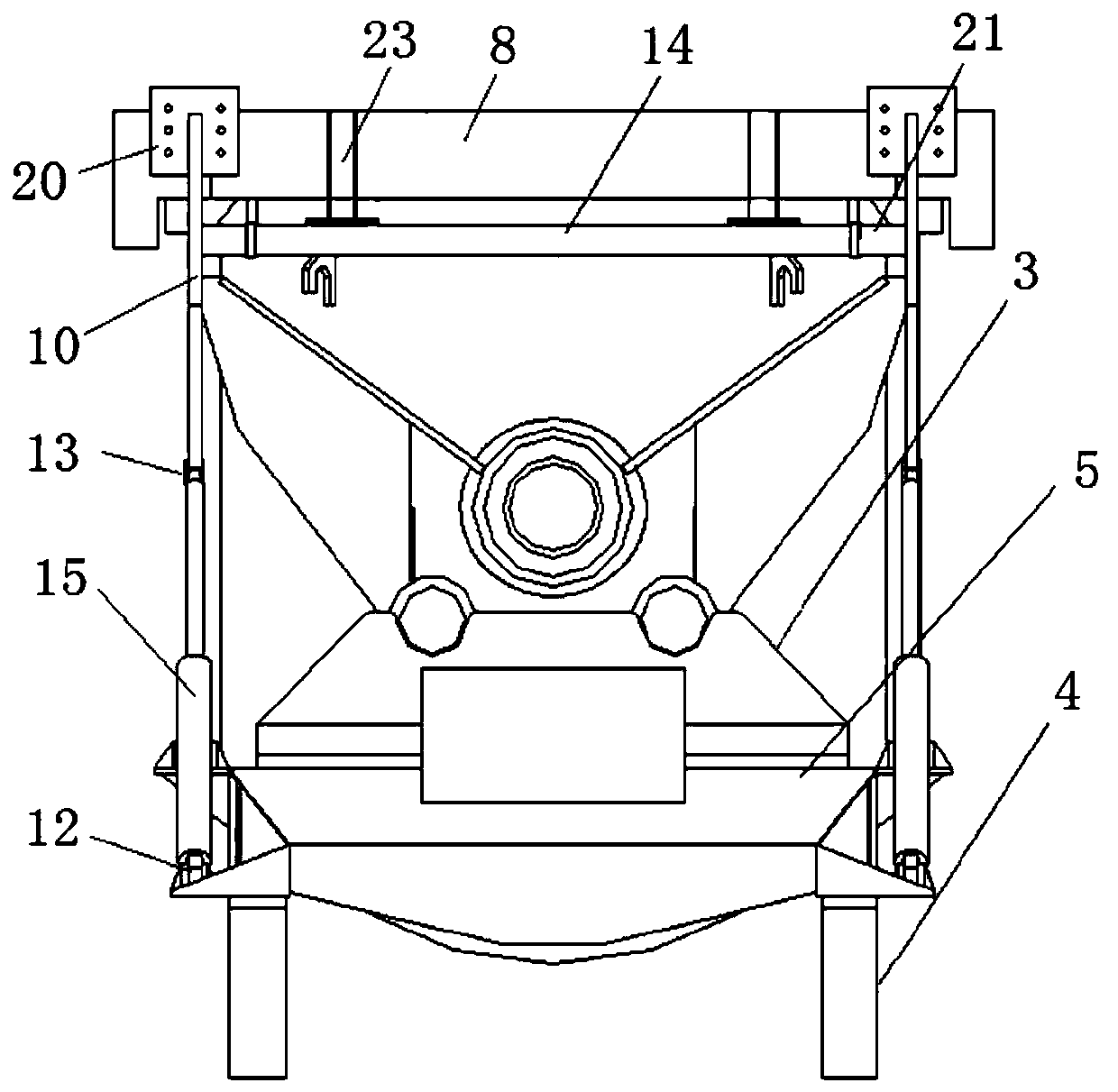

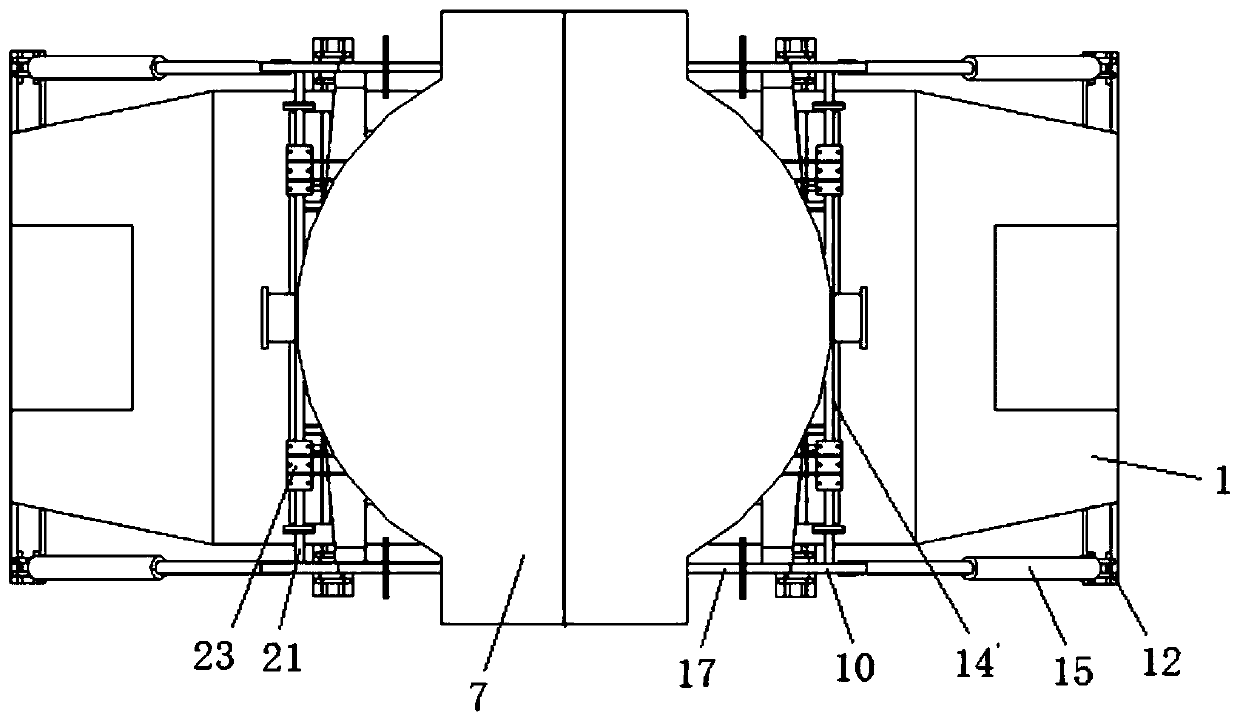

[0021] The present invention is made up of protective cover 6, support frame 9, hydraulic cylinder 15, hydraulic pump and hydraulic control device 16.

[0022] figure 1 , 2 , 3, 4, 5, 6, and 7 show that the protective cover 6 is relatively composed of two semicircular covers, and the two semicircular covers respectively include two semicircular top plates 7 and two vertically connected top plates 7 The side plate 8 with a semicircular circumference matches the top surface and the outer circumference of the upper opening of the molten iron tank 2 after the two semicircular covers are docked. opposite ends. When the molten iron tank 2 needs to be filled with molten iron or hoisted, the two semicircular covers of the protective cover 6 are opened on the front and rear sides; the two semicircular covers of the protective cover 6 are closed during transportation to prevent the molten iron heat loss.

[0023] figure 1 , 2 , 3 shows that two support frames 9 are respectively lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com