Gradual cambered chamfered mold with enhanced water cooling structure and design method

A chamfering crystallizer and crystallizer technology, which are applied in the field of billet continuous casting production, can solve the problems such as the inability to fully consider the thermal shrinkage of the corner of the crystallizer, the uneven distribution of the mold slag film and the air gap, and the uneven growth of the billet shell. , to prevent the accumulation of mold slag, improve the heat transfer at the corners, and inhibit the generation of corner defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The embodiment of the present invention is applied to the crystallizer of a 280mm×325mm bloom continuous casting machine in a certain steel factory. The mold length is 800mm. It is a tubular crystallizer and mainly produces high-carbon alloy steel such as bearing steel and cord steel.

[0045] The design method of present embodiment crystallizer is:

[0046] (1) Taking bearing steel GCr15 as the main production steel object, the measurement results of thermal contraction coefficient of bearing steel GCr15 when cooling from 1300°C to 500°C at different cooling rates are as follows: Figure 10 shown;

[0047] (2) According to the copper plate structure of the crystallizer, the size of the cast slab and the thermal contraction coefficient of the specific steel grade obtained from the measurement, a two-dimensional transient thermal-mechanical coupling calculation model is established with the 1 / 4 billet shell-mold cross-section system as the calculation object, The specif...

Embodiment 2

[0137] The embodiment of the present invention is applied to the crystallizer of a 360mm×450mm bloom continuous casting machine in a steel factory. The crystallizer length is 850mm. It is a four-sided combined crystallizer and mainly produces medium carbon alloy steels such as 45# and 40Cr.

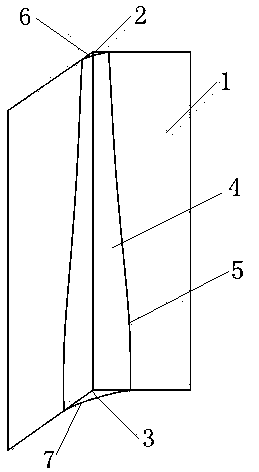

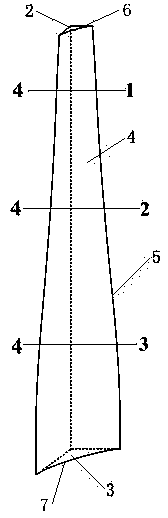

[0138] According to the method steps in the embodiment 1 related to the crystallizer, the progressive arc chamfering crystallizer with enhanced water-cooling structure finally obtained, such as Figure 1 to Figure 6 and Figure 9 As shown, with four such as figure 1 The symmetrically distributed upper chamfer 2 and four lower chamfers 3 shown are along the height direction of the crystallizer inner wall 1, from the upper chamfer 2 to the lower chamfer 3, and the chamfer angles are according to Figure 10 The heat shrinkage of the billet corner shown in the figure gradually increases, and the chamfered surface 4 formed between the upper chamfer 2 and the lower chamfer 3 is a gradual arc s...

Embodiment 3

[0145] The embodiment of the present invention is applied to the crystallizer of a 180mm×180mm bloom continuous casting machine in a certain steel factory. The crystallizer length is 800mm. It is a copper tube type crystallizer and mainly produces high-carbon alloy steel such as 72A.

[0146] According to the method steps in the embodiment 1 related to the crystallizer, the progressive arc chamfering crystallizer with enhanced water-cooling structure finally obtained, such as Figure 1 to Figure 8 As shown, with four such as figure 1 The symmetrically distributed upper chamfer 2 and four lower chamfers 3 shown are along the height direction of the crystallizer inner wall 1, from the upper chamfer 2 to the lower chamfer 3, and the chamfer angles are according to Figure 10 The heat shrinkage of the billet corner shown in the figure gradually increases, and the chamfered surface 4 formed between the upper chamfer 2 and the lower chamfer 3 is a gradual arc surface, and the transi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com